Description

What is a Water Manifold?

All Inline water manifolds are sized to meter the flow of each circuit. The inlet port Size is the same as, or larger than, all outgoing ports combined. This maintains high flow and efficient cooling.

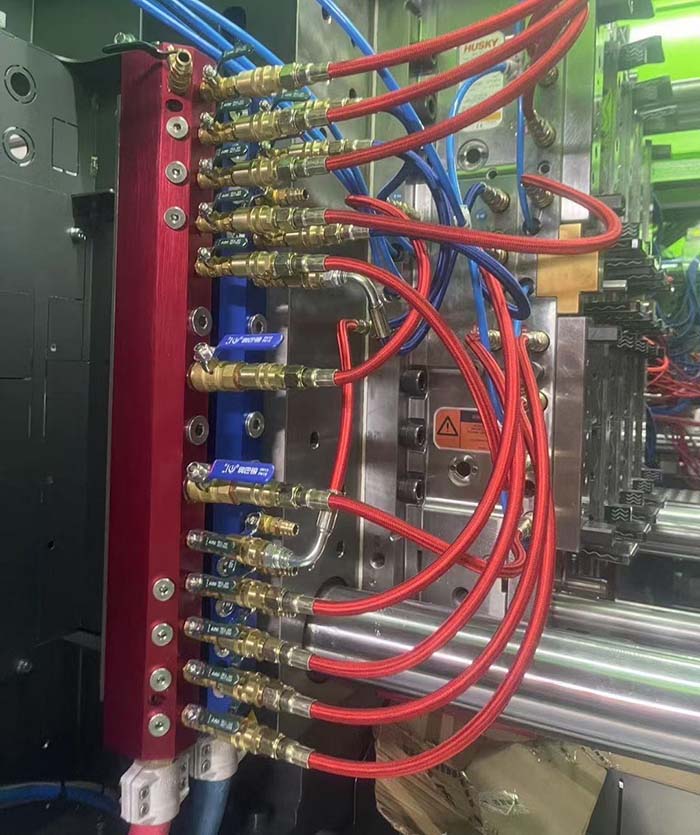

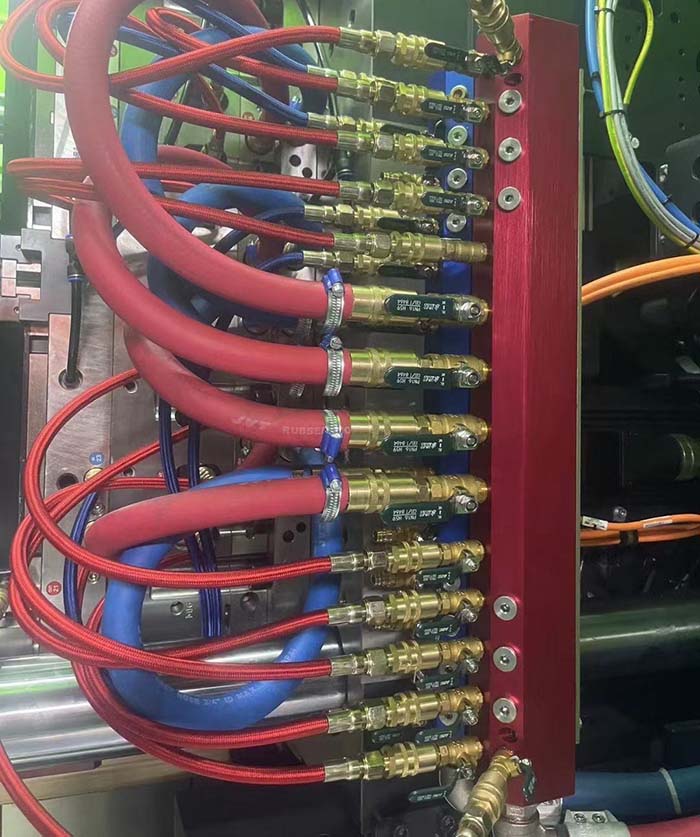

Mold Cooling Water Manifolds are common auxiliaries in plastic injection mold components. They are key components of mold water cooling circuits.

Their primary function is to route cooling water from the tower or chiller to the water passages in the mold, then collect the warmer water leaving the mold, at turbulent flow rates, and return it to the external cooling water loop.

Practical Use:

You can specify the model size, number, and location of all outlet and inlet ports to achieve precision flow patterns for your particular applications.

Convenience, cost, and increased production are the advantages of utilizing external Manifolds.

These rugged, low-cost aluminum manifolds mount directly on the mold and are connected to the water lines with quick disconnect fittings.

DGMF Mold Clamps Co., Ltd has a complete series for the IM3, IM4, IM6, IM8, and IM9 water manifold, please contact us for more detailed specifications.

CMS/CITO mold manifold specification introduction:

1) IM3 series

Example: IM3-2-AB-4-1/4-BLUE IM3-2-AB-2-2-B/R

Example: IM3—4-C-1/4 IM3-4-C-2-2-1/4/B/R

2) IM4 series (1 inch)

Example: IM4-9-ABC-6-6-1/4-B/R

3) IM6 series (1-1/2 inch)

Example: IM6-14-B-6-3/8-N-BLUE

4) IM8 series (2 inches)

Example: IM8-17-C-6-1/2-N-BLUE

What should I do if a thick water pipe is connected to several or dozens of thin water pipes? Need to convert the water manifold in the middle.

Generally, large molds with more waterways are only needed. There are dozens or even hundreds of waterways connected by the mold, and there are not so many connections on the cooling waterside. Only connect the water channels from the mold to the water manifold first, and then connect the water manifold to the cooling waterside.

Most aluminum manifolds are color-anodized after machining to provide corrosion resistance from the cooling water. Typical color choices are red and blue.

Red and blue anodizing are the most popular because of the convention; blue denotes cooler supply water and red the warmer water returning from the mold.

Color coding reduces the chances of incorrect water hose hook-up after a tool change and set-up.

Product features of mold water manifold:

1. The mold water manifold is a device that collects the low-temperature water in each channel after separate heat dissipation and then returns to the return water main system.

2. Not only saves space but also the operation is relatively simple. Easy to use, easy to disassemble, and install.

3. Straight-line multi-branch water manifold makes it easier to design and install the water route pipe of the mold;

4. A variety of joints of teeth can be used in a wider range, and the thread can be processed according to user requirements;

5. The outer surface has blue and red treatment, which makes it easier to distinguish water in and out during use.

6. Ports can be drilled in from 1 to 5 surfaces – A, B, C, D, and/or E . Custom spacing is available.

Water manifold in automobile molds

In automobile molds, it is necessary to set up multiple waterways to cool the mold in time to ensure the stability of the mold during the molding process.

The temperature difference will cause local stress concentration, poor fluidity during the product molding process, and bubbles are generated, which directly affect the product.

The quality, strength, and hardness are right angles because the water system is an important part of the mold-forming process. The specifications of the water circuit are set according to the cooling speed requirements and the design of the mold space.

Different water circuits are also set according to the characteristics of different products. The design of different waterways has different diameters. Each waterway needs to be connected to a mold injection molding machine.

When the injection molding machine structure matches the waterway structure specification department, a conversion joint is required.

If the number of waterways on the mold exceeds the number of waterways supplied by the injection molding machine, The water path on the mold needs to be connected in series with the injection molding machine to meet the supply of the number of water paths.

But the path of the water path becomes much longer, and the cooling water is formed in the first half of the water path to have a good cooling effect, and in the second half of the water path the section formation is affected by the high-temperature mold and the temperature rises, the cooling effect of the second half-section is greatly reduced, the cooling speed slows down, and the water pressure supply is unstable in the waterway process, which is not conducive to the rapid cooling of the mold.

DGMF Mold Clamps Co., Ltd provides integrated Aluminum Water Manifolds with a simple structure, a convenient connection of injection molding machine and mold waterway, and a guarantee of waterway supply.

We also supply Cooling Circuit Plugs, Mold Cooling Cascade Water Junctions Cooling Pipes, Mold Cooling Component Baffle Boards, Mold Cooling Hose Nipple Pipe Fittings, Quick Release Connector Plugs Hose Fittings Tube Fittings, etc.

Contact the DGMF team for the mold cooling component specification, inventory, and pricing.

DGMF Mold Clamps Co., Ltd is a mold clamps Manufacturer in China, also provides injection mold components, die press components, machine tools, and fasteners for your best choice. Contact us for more details.

Reviews

There are no reviews yet.