Description

What are Quick Release Connector Plugs Hose Fittings Tube Fittings?

Quick Release Connector Plug is a connector plug that can realize a pipeline connection or disconnection without auxiliary tools.

Mold quick release connector plug classification

A, according to the angle: 180 degrees, 90 degrees, 45 degrees.

According to the method of use: connecting hose nipples (pagoda shape), connecting Teflon tube fittings (outer teeth 3/8H, 1/2H), connecting oil pipe quick release couplings (inner teeth).

Quick release connector plugs also called mold temperature control joints, die temperature control fittings, quick release nozzles, quick release couplings, quick release gas couplings, quick release hose couplings, etc.

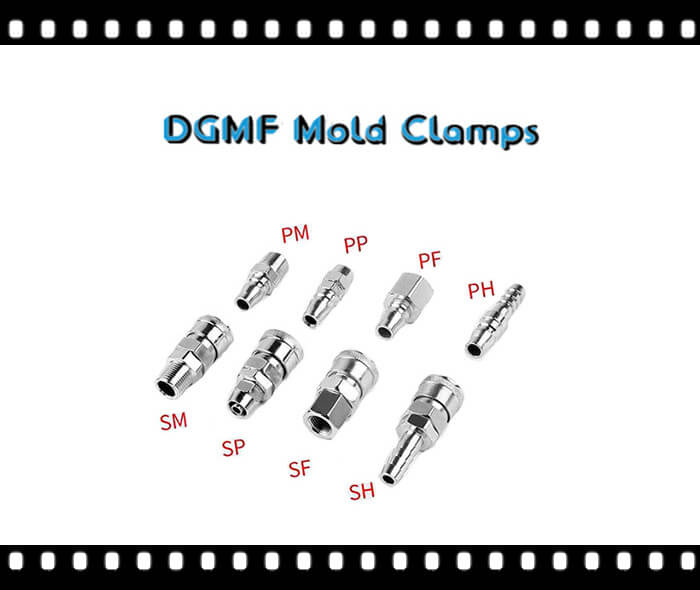

Mold quick release connector plug pictures

Mold temperature control joint (female) and mold quick release connector hose nipple/nozzle (male), it has three structural forms.

- The mold temperature control joints and mold quick-release nozzles are closed.

The mold cooling nozzle must be a standard length, the mold temperature control joints and mold quick-release nozzles are open, and the mold temperature control joints are closed. The mold quick-release nozzles are opened.

When not connected

The female head and the male head are against the tube channel under the action of their respective ejector pin and spring, and the male and female ejector pis are closed respectively, instantly blocking the flow of fluid.

When connected

When the male head is inserted into the female head, the ejector pin returns to the original position under the action of the spring, and the steel ball rolls and locks the male head to be tightly connected. At the same time, the ejector pin of the female head and the male head push each other to open, fluid flow, O-ring can completely block fluid leakage.

- The mold temperature control joints and mold quick-release nozzles are opened.

Not connected

When the copper jacket of the female head is pushed to the other end, the steel ball automatically rolls outward, so the male head is moved out; since neither the male head nor the female head has a valve, the fluid flows out.

Connected

When the male head is inserted into the female head, the copper jacket is pushed to the previous position by the force of its spring to lock the steel ball, and the fluid flows, and the O-ring prevents the fluid from flowing out.

- Open mold quick release nozzle and closed mold temperature control joint.

When not connected

When the copper jacket of the female head is moved to the other end, the stainless steel ball automatically rolls outward, and the male head is bounced by the reaction force of the valve spring, and the valve can be automatically closed to block fluid flow.

Connected

When the male head is inserted into the female head, the copper jacket is pushed to the previous position by the force of its spring to lock the steel ball, and the fluid flows, and the O-ring prevents the fluid from flowing out.

The purpose of choosing mold quick release connector plugs.

- Time-saving and labor-saving

When disassembling and connecting water, oil, and air circuits through quick connectors, the action is simple, saving time and manpower.

- Save fuel, water, and gas

When disassembling the pipeline, the single valve on the quick connector can close the pipeline so that the fluid will not flow out to avoid fluid loss.

- Environmental protection

When the quick connector is folded and connected, the fluid will not be missed, and the environment is kept clean.

- The equipment is divided into parts for easy transportation.

Large equipment or hydraulic tools that need to be easily carried can be transported after being disassembled using quick connectors, and then assembled and used after reaching the destination.

- Economy

All the above advantages create economic value for customers.

According to the form of use, it can be divided into quick-release gas couplings for air, quick release hose couplings for oil pressure, quick release connector plugs for cooling water temperature, and quick release connector hose couplings for oil temperature.

- Quick release connector gas couplings for air: mainly used for air piping and pneumatic tool accessories. Corresponding to its use, there are a variety of body materials, sizes, and installation shapes.

Precautions for use

1). Please do not use it for purposes other than quick fluid couplings.

2). Please do not use fluids other than applicable fluids.

3). Please do not connect with quick fluid couplings produced by other companies.

4). Do not exceed the maximum operating pressure during use.

5). Do not use outside the temperature range to prevent wear or leakage of the sealing material.

6). Do not hit, bend, or stretch artificially to prevent damage.

7). Do not use it in places mixed with metal powder or sand dust to prevent poor work or leakage.

8). Adhering to debris will cause poor work or leakage.

9). Do not disassemble the quick release connector plug.

- Quick release connector gas coupling for hydraulic: mainly used for hydraulic devices and construction machinery. The main material should be made of metal that can resist vibration and shock. The size and installation shape are rich and varied.

Precautions for Use (Warning)

1) Please do not use fluids other than applicable fluids.

2) Do not exceed the maximum operating pressure limit during use.

3) Do not use outside the temperature range to prevent wear or leakage of the sealing material.

4) Do not disassemble.

Precautions for use (note)

1). The external thread of the control thread should use special thread sealing material.

2). During installation, the applied torque should not exceed the maximum torque to prevent damage.

3). Please do not use it for purposes other than quick connectors.

4). Please do not connect with quick fluid couplings produced by different companies, as this may cause poor sealing.

5). Don’t hit, bend or stretch artificially to prevent damage.

6). Do not use it in places mixed with metal powder or sand dust to prevent poor work or leakage.

7). Adhering to debris will cause poor work or leakage.

8). If it is used in a machine with vibration or impact, it will cause the cause of reduced durability.

9). Do not use water and glycol series media. Such substances will cause the zinc coating on the surface to dissolve.

10). The fluid used must be clean fluid filtered by a filter.

11). The O-ring seal must always be kept with oil when used.

12). The flow velocity of the fluid should be kept below 8m/s during use.

- Quick-release coupling plugs for cooling water temperature and quick release connector hose coupling for oil temperature: mainly used for general-purpose mold interfaces. Completely realize the simplification of the mold exchange operation, strengthen the anti-rust function, and have a variety of types.

Precautions for use (note)

1). Please do not use fluids other than applicable fluids.

2). Do not exceed the maximum operating pressure limit during use.

3). Do not use outside the temperature range to prevent wear or leakage of the sealing material.

4). Don’t hit, bend or stretch artificially to prevent damage.

5). Do not use it in places mixed with metal powder or sand dust to prevent poor work or leakage.

6). For the installation of threads, do not exceed the maximum tightening torque during installation to prevent damage.

7). Do not use hoses with cracks to prevent leakage or falling off.

8). If it is used in a machine with vibration or impact, it will reduce durability.

9). The fluid used must be clean fluid filtered by a filter.

10). Do not disassemble the quick connector.

Reviews

There are no reviews yet.