Guide Components

-

Stopper And Spring For Ball Bearing Guide Post Sets

Read more -

Slide Core Guide Parts

Read more -

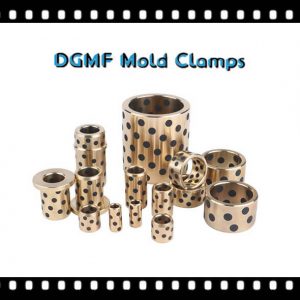

Self-lubricating Guide Bushings For Injection Molding

Read more -

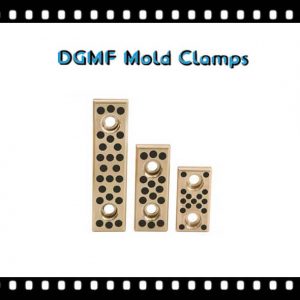

Self-lubricating Bronze Wear Plate

Read more -

Oilless Slide Core Guide Units

Read more -

Mold Guide Bush Component Guide Bushing

Read more -

Guide Pins For Injection Molding

Read more -

Guide Pins And Bushings

Read more -

Ball Cages For Die Sets

Read more -

Ball Bearing Guide Post Sets For Die Guides

Read more

Guide Components Supplier

DGMF Mold Clamps Co., Ltd is the injection molding guide components supplier and mould clamps manufacturer in China.

What are the Guide Components?

The guide component refers to a component that plays a guiding role in the fixture.

The mold guide components mainly include guide bushings, guide pins, guide plates, etc.; in addition, there is a cone positioning structure.

Guide Components Function

Its function is to ensure accurate guidance when the upper mold and the lower mold move relative to each other, so that there is a uniform gap between the convex and concave molds and improve the quality of the stamping components.

The guiding component element in the mold mainly plays the role of guiding and positioning during the mold closing process.

The guide pin is a guide sleeve for the piston rod filled with PTFE material, which supports and guides the piston rod and prevents dust.

The guiding parts and positioning parts of the stamping die are important components of the stamping die. They play a pivotal role in the entire die.

Do you know the characteristics of the guiding and positioning parts of the stamping die? To understand the mold, you must first understand the characteristics of the guide components.

Guide Components Characteristics

The guide bushing supports and guides the piston and piston rod of the reciprocating hydraulic cylinder. Comply with GB/T15242.2—94, the material is PTFE+copper powder, phenolic cloth.

The guide pins and guide bushings are the most widely used guide components. Its function is to ensure that the convex and concave dies have a precise fit clearance during the stamping work.

Therefore, the gap between the guide bushing and the guide sleeve pin should be smaller than the blanking gap. The guide bushing is set on the lower mold base, and the upper-end surface of the guide bushing is at least 5 to 10 mm above the top surface of the upper template at the bottom dead center of the stroke.

The guide bushing should be arranged far away from the module and the pressing plate so that the operator’s arm does not need to cross the guide bushing to feed and take materials.

Supporting and clamping parts include upper and lower templates, die handles, convex and concave die fixing plates, backing plates, stoppers, etc.; the upper and lower templates are the basic parts of the die; various other parts are installed and fixed on it.

The plane size of the template, especially the front and rear direction, should be compatible with the workpiece, too large or too small is not conducive to operation.

The guide pin and guide bushing in the mold base is the typical shaft and sleeve parts. They play a guiding role in the mold to ensure that the punch and the concave mold have the correct relative position when working.

In order to ensure good guidance, the guide After the column and the guide set is matched, it should be ensured that the movable part of the mold base moves smoothly, has no blocking phenomenon, and is wear-resistant.

Therefore, the dimensional accuracy and shape accuracy of the guide bushing and the guide the coaxiality between the mating surface of the bushing and the guide sleeve pin.

DGMF Mold Clamps Co., Ltd manufactures the mold clamps, and supplies the injection mold components, such as Clamps, Toggle Clamps, C Clamps, Pins, Bushings, Positioning Components, Lock Mold Components, Reset Extrusion, Cavity, and Core Components, Coolings, Die Press Components, Punch And Die, Guide Components, Self-lubricating Components, Springs, Machine Tools, gate valves, Machine Mounts, Vises, Fasteners, Lifting, Bolts, Nuts, Washers, etc.

Contact the DGMF Mold Clamps teams for more details about the guide components such as guide components specifications, guide components pricing, guide components inventory, etc.

Showing all 10 results

-

Ball Bearing Guide Post Sets For Die Guides

Read more -

Ball Cages For Die Sets

Read more -

Guide Pins And Bushings

Read more -

Guide Pins For Injection Molding

Read more -

Mold Guide Bush Component Guide Bushing

Read more -

Oilless Slide Core Guide Units

Read more -

Self-lubricating Bronze Wear Plate

Read more -

Self-lubricating Guide Bushings For Injection Molding

Read more -

Slide Core Guide Parts

Read more -

Stopper And Spring For Ball Bearing Guide Post Sets

Read more