Lifting

-

Three In One Multi-functional Combination Eyebolt For Lifting

Read more -

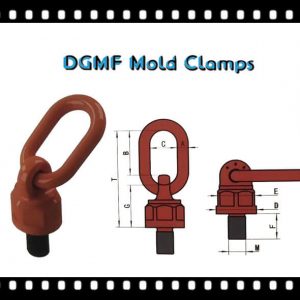

Swivel Eye Bolt For Lifting

Read more -

Lifting shackles Bow Dee and Safety Pin Shackles

Read more -

Lifting Eyebolts Screw Type Lifting Points

Read more -

Lifting Eye Nuts DIN 582

Read more -

Heavy-duty Machinist Screw Jacks For Lifting Molds

Read more

Lifting Components Supplier

DGMF Mold Clamps Co., Ltd is the lifting components supplier and mould clamps manufacturer in China.

1. What is Lifting Sling

The lifting sling refers to the device for lifting heavy objects in lifting machinery. The most commonly used slings for lifting finished items are hooks and slings, as well as rings, lifting suction cups, clamps, and forks. It is widely used in the hoisting industry.

Lifting Sling Introduction

Special rigging such as hooks, wire ropes, and chains are commonly used in slings. Lifting suction cups, clamps and forks can be used on cranes as special spreaders for a long time, and can also be used as replaceable auxiliary spreaders to hang on hooks for temporary use. They are often used in warehouses and yards of multiple cargoes to improve Operational efficiency.

The spreader for grabbing bulk materials is generally a grab bucket with open and closed jaws, and electromagnetic chucks can also be used to suck magnetic materials such as metal chips. Spreaders for lifting liquid materials are commonly used in buckets and hanging tanks.

Generally, molten steel or chemical solutions are discharged by tilting or bottom plugging, and liquid materials such as concrete are discharged by opening the bottom door of the hanging tank.

In order to meet the daily maintenance and lifting of large machinery, some domestic sling companies have also designed some special slings, such as fan slings, tower slings, blade slings, hub slings, steam turbines, and other non-standard slings.

Lifting Sling Classification

The spreaders mainly include chain spreaders, clamp spreaders, lifting suction cups, and so on.

Chain spreader

Overview

The chain sling is composed of slings, rings, hooks, slings, and other accessories. It is a metal sling. According to the carrying capacity, it is divided into the 60-class sling, 80-class sling, 100-class sling, and 120-class sling. Wait. The higher the level, the higher the carrying capacity of the chain of the same specification.

Advantage

1) High carrying capacity

2) Good safety, breaking elongation ≥20%

3) Various combination forms, strong versatility, and interchangeability

4) Adjustable length, easy to store

5) Long service life

6) Large operating temperature range

7) Easy to detect, convenient and fast

Disadvantages:

1) The price is higher than suspenders and wire ropes

2) Heavyweight

Clamp spreader

Clamp-type spreaders usually refer to clamps, tools used for clamping, fastening, or hoisting.

Mechanical lever-type slab clamp

Uses

Widely used in the handling and loading and unloading of slabs in the continuous casting workshops of the steelmaking plants of the iron and steel metallurgical enterprises, the slab warehouses of the hot rolling mills, and the stations, freight yards, and terminals of the transportation industry.

Types

1. According to the different connection methods with the crane, it can be divided into single lug type, double lug type, double pulley group type, and double pulley group guide cylinder type.

2. According to the temperature of the slab being lifted, it is divided into normal temperature type and high-temperature type.

Features

1) No need for power supply, easy to use, maintenance-free, reliable, safe, and convenient to operate.

2) Generally, it is suitable for conveying slabs one piece at a time or a fixed number of blocks, or a number of blocks in a cyclic state. The number of blocks can be designed to be adjustable, but it is not suitable for places where the number of blocks changes frequently.

3) The operating efficiency is relatively low.

Automatic lever clamp

Automatic lever clamp Uses

Suitable for slab loading in steel mills.

Automatic lever clamp Features

It can automatically realize the transition between lifting 1-2-1 blocks, and the number of lifting slabs constantly changes regularly. At the same time, 1 slab or 2 slabs can be fixed and lifted, and only need to make simple adjustments.

Electric lever-type slab clamp

Type

Type 1 is divided into double ear type, double pulley group type according to the different connection modes with the crane.

Type 2 is divided into normal temperature type and high-temperature type according to the temperature of the slab being lifted.

Uses

It is widely used in the handling and loading and unloading of slabs in the continuous casting workshops of the steelmaking plants of the iron and steel metallurgical enterprises, the slab warehouses of the hot rolling plants, and the transportation stations, freight yards, and wharves.

Features

1) Mechanical gravity self-locking, safe and reliable to use;

2) Equipped with clamping, limit, simple operation;

3) Suitable for handling one too many slabs at a time;

4) The work efficiency is higher than the mechanical automatic type;

5) There is a change in the height direction during the opening and closing of the jaws, and certain experience is required for the operation, but the height change can be compensated by linkage with the crane lifting mechanism to solve the height change problem.

Electric translational slab clamp

Electric translational slab clamp Uses

Widely used in the handling and loading and unloading of slabs in the continuous casting workshops of the steelmaking plants of the iron and steel metallurgical enterprises, the slab warehouses of the hot rolling mills, and the stations, freight yards, and wharves of the transportation industry.

Electric translational slab clamp Features

1) Mechanical gravity self-locking, safe and reliable to use; the feature is that after the boom with jaws clamps the slab, as the vehicle lifts, the boom slides down the fixed slope slide while clamping the slab Getting tighter. Finally, the movable arm and the fixed arm are integrated. The heavier the slab, the greater the clamping force.

2) Equipped with clamping and limit position, the operation is simple and convenient; the clamp opening and closing transmission device are equipped with a magnetic powder clutch and a zero-speed switch. When the slab is clamped, the load increases, and the magnetic powder clutch slip. When it is zero, the zero-speed switch detects it and the clamping signal light is on.

3) Suitable for handling one too many slabs at a time. For the 94t clamp, it can clamp 1~4 pieces, which can be detected by the cam switch of the height detection device.

4) The operating efficiency is relatively the highest. It can be made into an automatically controlled slab clamp. For example, it is used for roller table feeding in a hot rolling mill.

5) The cost is relatively high and the maintenance is relatively complicated. The electronic control system and the cable reel were added; the transmission equipment, the motor, the reducer, the magnetic powder clutch, and the electromagnetic brake were added; the detection device and equipment were added, such as clamping detection, opening detection, stroke limit position detection, and height detection.

6) Computer management of slab library can be realized.

Automatic lever-type billet clamp

Automatic lever-type billet clamp Uses

Widely used in the handling and loading and unloading of billets in the continuous casting workshops of the steelmaking plants of the iron and steel metallurgical enterprises, the billet warehouses of the hot rolling mills, and the transportation industry stations, freight yards, and wharves.

Automatic lever-type billet clamp Types

Type 1 According to the different connection modes with the crane, it is divided into a single lifting point, double lifting point, single and double universal lifting point.

Type 2 According to the temperature of the billet being lifted, it is divided into normal temperature type and high-temperature type.

Automatic lever-type billet clamp Features

1) No power supply, no ground manual assistance, only the driver can directly control the lifting operation; simple to use, maintenance-free, safe, and reliable operation.

2) Generally suitable for handling one or more billets at a time.

3) Higher operating efficiency.

Mechanical lever-type vertical roll clamp

Mechanical lever-type vertical roll clamp Uses

Widely used in the lifting of vertical coils in the annealing workshop of cold-rolled strip mills and finished products workshop. It is also suitable for the loading, unloading, and handling of stations, freight yards, docks, and large-scale users.

Mechanical lever-type vertical roll clamp Features

1) Automatically complete the opening and closing of the jaws with the lifting of the crane hook, the mechanical gravity self-locking, easy to use, safe, and reliable.

2) Floating pallets are set at the junction with the end surface of the steel coil to ensure that the end surface of the steel coil is not damaged. Suitable for lifting and transporting cold-rolled vertical coils with thin plates (3~0.3mm).

3) Generally, it is not suitable for annealed vertical coils (silicon steel coils) whose coil thickness is less than 0.3mm, which is easy to cause deformation of the coil.

Lever-type internal and external clamp vertical roll clamp

Lever-type internal and external clamp vertical roll clamp Uses

Widely used in the finished product workshop and heat treatment workshop of cold-rolled silicon steel sheet plants, and also suitable for the finished product workshop of cold-rolled strip steel plants.

Lever-type internal and external clamp vertical roll clamp Features

1) Automatically complete the opening and closing of the jaws with the lifting of the crane hook, mechanical gravity self-locking, easy to use, safe, and reliable;

2) The steel coil is clamped by internal tensioning and external clamping, with balanced lifting force and will not cause deformation of the steel coil;

3) Ensure that the constant center of gravity raises and lowers the coil without causing damage to the coil end.

4) The expanded size is relatively short, but the overall length is large, and the manufacturing cost is relatively high.

5) It is especially suitable for lifting and transporting steel coils with thin plates (plate thickness less than 0.5mm).

Electric translational horizontal roll lifting pliers

Electric translational horizontal roll lifting pliers Uses

Widely used in the hoisting of cold-rolled horizontal coils in cold-rolled strip steel plants, especially automobiles. It is also suitable for the handling and loading and unloading of raw steel coils in car factories and electrical appliances factories.

Electric translational horizontal roll lifting pliers Features

1) Fully equipped automatic detection and control system, with alignment, clamping photoelectric detection and load, limit state sensing detection and automatic control functions, and setting status indicator lights to display each state, the operation is very safe and convenient.

2) With power-off self-locking, load self-locking, transmission chain torque protection, to ensure the absolute safety and reliability of the spreader.

3) Floating contact steel coil end face device, polyurethane jaw protection, and introduction protection, to ensure that the steel coil is not damaged at all.

4) The rigidity of the system is poor, which is not suitable for the hoisting of hot rolled high-temperature coils.

Electric lever-type horizontal roll lifting pliers

Electric lever-type horizontal roll lifting pliers Types

According to the temperature of the hoisted steel coil, it is divided into normal temperature type and high-temperature type.

Electric lever-type horizontal roll lifting pliers Uses

Widely used in hot-rolled strip steel plants of metallurgical enterprises, and also suitable for the hoisting of hot-rolled horizontal coils by users of stations, freight yards, wharves, and large-scale steel coils.

Electric lever-type horizontal roll lifting pliers Features

1) The system has a good lubrication effect, self-lubricating can be realized, and maintenance is simple and convenient

2) Compact structure and smallest width dimension.

3) The height dimension is relatively high.

Mechanical lever-type horizontal roll lifting pliers

Mechanical lever-type horizontal roll lifting pliers Purpose

Suitable for the lifting of horizontal rolls in stations, freight yards, wharves, and other occasions.

Mechanical lever-type horizontal roll lifting pliers Features

1) No need for a power supply, a wide range of applications, especially outdoor occasions.

2) The use requires a high level of operation.

3) The outer diameter of the steel coil should not change too much.

4) The operating efficiency is relatively low.

Hydraulic lever-type horizontal roll lifting pliers

Hydraulic lever-type horizontal roll lifting pliers Uses

Widely used in hot-rolled strip steel plants of metallurgical enterprises, and also suitable for the hoisting of hot-rolled horizontal coils by users of stations, freight yards, wharves, and large steel coils.

Hydraulic lever-type horizontal roll lifting pliers Features

Compared with the electric lever-type horizontal roll, it has the following features:

1) The system has good flexibility, fast opening and closing speed, and high operating efficiency.

2) Not suitable for high-temperature steel coils, and the cost is relatively high.

3) The maintenance difficulty is high, and the hydraulic system is prone to oil leakage.

Horizontal roll C-hook spreader

Horizontal roll C-hook spreader Classifications

1) According to the cross-section of the hook body, it is divided into structural type, plate type, and box beam type.

2) According to the type of hook liner, it is divided into copper liner type, aluminum liner type, and polyurethane liner type.

Horizontal roll C-hook spreader Uses

Widely used in hot-rolled strip mills and cold-rolled strip mills of steel mills, and also suitable for lifting and transporting various horizontal coils of stations, freight yards, wharves, and large steel coil users.

Horizontal roll C-hook spreader Features

1) Low cost and easy maintenance.

2) There are restrictions on the stacking spacing or lifting order of steel coils.

3) The operating efficiency is relatively low.

Electric translational plate stack lifting clamp

Electric translational plate stack lifting clamp Uses

Widely used in hot rolling production lines, used for plate stack handling and loading and unloading vehicles.

Electric translational plate stack lifting clamp Features

1) The horizontal spacing of each group of clamp legs can be adjusted electrically, which is convenient to use, especially suitable for lifting long plate stacks to ensure that the steel plate will not be deformed due to lifting.

2) Larger structure and higher cost.

Automatic lever-type lifting pliers

Automatic lever-type lifting pliers Uses

Suitable for loading and unloading wide and heavy plates in metallurgical enterprises’ rolling mills, wharves, and station freight yards.

Automatic lever-type lifting pliers Features

1) Compared with the electric translation type middle plate spreader.

Advantages

Lighter weight, unrestricted use environmental conditions, low cost, simple maintenance, especially suitable for occasions with large plate width (the plate width can be changed up to 1.5 m~4.8m).

Disadvantages

The number and thickness of steel plates to be lifted cannot be changed frequently, and adjustment is relatively troublesome.

2) Compared with electric disk-type spreaders, it has a relatively lightweight, low cost, simple and convenient maintenance, and high safety factor, especially when it is shipped.

The disadvantage is that the number and thickness of the steel plates to be lifted cannot be changed frequently, and the adjustment is relatively troublesome.

Lifting the suction cup or hoisting the suctorial cup

A sling that uses magnetic force or air pressure difference to absorb heavy objects. There are two types: electromagnetic chuck and vacuum chuck.

①Electromagnetic chuck

It is composed of a disc-shaped steel shell and an excitation coil in the shell to absorb magnetically conductive materials. It is also called a lifting electromagnet.

It is usually hung on a crane hook for use, and its cable rises and falls together with the hook. According to the working principle, it can be divided into the electromagnetic type and permanent magnet type.

The electromagnetic type relies on the coil to pass the direct current to excite the material to attract, and the power is off to demagnetize and discharge the material.

In order to prevent the material from falling when the power is cut off, the crane with this kind of suction cup generally needs a backup power supply.

The permanent magnet type relies on permanent magnets (such as AlNiCo or strontium ferrite alloy magnetic steel suction heads) to absorb materials, demagnetize and discharge materials when the power is turned off, there is no danger of falling materials when the power is off, but it is easy to adsorb iron filings and oxidation when the demagnetization is not clean Skin, affect the suction. The round electromagnetic chuck is most used.

Rectangular electromagnetic chucks are often used when picking up plates and strips. The bottom surface of the suction cup is mostly flat; there are also concave arcs for sucking barrels and coils.

When lifting long items, you can use several suction cups to work at the same time. The temperature of the material sucked by the electromagnetic chuck generally does not exceed 600 ℃.

②Vacuum sucker

It consists of a vacuum device and soft plastic or bowl-shaped rubber suction cup head, etc.

It is divided into two types, power, and no power.

The power vacuum suction cup uses a vacuum pump to obtain a vacuum, which has a large suction force, but is noisy, and needs to be attached with a cable or a ventilation hose.

Unpowered vacuum suction cups are also called self-priming vacuum suction cups. When the suction cup is lifted, the hook drives the piston rod to obtain a vacuum.

It does not require a power source. It has the advantages of simple structure and no noise, but it can only suck materials under 500 kg. Vacuum suction cups are often used to pick up items with a flat surface.

The sucked materials are not restricted by magnetic permeability. Steel plates, glass, plastics, cement products, and wood can be sucked and transported, and materials can be taken one by one from a stack of plates. The work efficiency is high.

3. What is Lifting Point?

In the hoisting operation, the connecting part between the hanging object and the hanging object is called the lifting point.

When lifting various objects, in order to avoid tilting, overturning, deformation, and damage of the objects, the lifting points should be correctly selected according to the shape characteristics of the objects and the position of the center of gravity, so that the objects have sufficient stability during the lifting process to avoid occurrence accident.

The high-quality lifting points have complete quality control measures, passing spectral analysis, magnetic particle inspection, eddy current testing, evidence load testing, dynamic fatigue resistance testing, and ultimate breaking load testing.

The lifting point levels are now divided into 100, 80, 70, etc., and the lifting points of 80 and above adopt or refer to EU standards. The higher the level, the greater the strength and the stricter the quality requirements. Domestic companies have been developing 100-level lifting points.

Lifting point Application selection

1. The lifting point with a higher strength coefficient is preferred;

2. The hoisting point should be selected on the upper part of the center of gravity of the hoisting object, which has reliable stability;

3. In order to prevent overturning, swinging, and tilting during lifting and transportation, the lifting point and the center of gravity of the suspended object should be on the same vertical line

4. The hoisting object structure selected by the hoisting point can bear all loads.

5. When multiple cranes are used for lifting, the lifting point should be a position with a smaller crane amplitude.

6. The lifting points of slender objects should be selected for multi-point lifting by calculating the strength.

7. When the installation accuracy of mechanical equipment is high, in order to ensure safe and smooth assembly, the auxiliary lifting point can be used with a simple spreader to adjust the required position of the machine. The chain hoist is usually used to adjust the position of the body.

8. When the object is hoisted, it is generally used to turn over. Choose the hanging point below the object’s center of gravity, or choose the hanging point on the side of the object’s center of gravity.

As a rigging connector, it can be used alone according to the hoisting needs, and the ring can also be used with various rigging. Its product specifications and varieties are complete.

4. What is a lifting clamp?

A lifting clamp is a tool for clamping, fastening, or hoisting

The composition of the lifting clamp

A tool used for clamping, fastening, or hoisting. Clamps are divided into clamps and tailstock clamps according to the different objects to be clamped.

The lifting clamp is mainly composed of seven parts: hanging beam, connecting plate, opening, and closing mechanism, synchronizer, clamp arm, support plate, and clamp teeth.

Hanging beam

The lifting clamp is a component connected to the crane hook and has three structures: ring shackle connection, sling connection, and lug connection.

The lifting link shackle-type connecting the lifting shaft improves the force of the spreader and also avoids the decoupling phenomenon when loading and unloading the billet, reduces the height of the clamp itself, and is beneficial to use in low places. The sling is connected to the hanging shaft to make the clamp better.

However, the height of the sling is large and it needs to be used in a tall place. When hanging the hook, manual auxiliary hooking is required. The lug-type connecting crane shaft can be directly hooked by the crane operator, but during the lifting operation, the spreader must be placed on the ground and the hook should be lowered until it is not stressed. This will easily cause the hook to unhook.

Link

The connecting rod is the connecting piece of the hanging beam and the clamp arm.

Opening and closing mechanism

The opening and closing mechanism have a manual lifting lever type, (automatic) double hook type, (automatic) single hook type, (automatic) rotating lock type, etc.

The automatic opening and closing mechanism is a mechanism that realizes the automatic opening and closing of the billet fixture.

The action does not require any external power source, and the automatic opening and closing of the clamp is realized by the gravity of the clamp itself.

Lubrication of opening and closing mechanism: Lubricating oil (or engine oil) must be added regularly (2~3 days), and then move up and down several times until the lubrication is complete. Do not add excessive grease to lubricate!

Synchronizer

The synchronizer is a device to ensure the synchronous action of the clamp arms of the clamp.

Clamp arm

The clamp arm is the main force-increasing component of the clamp, through which the billet is clamped.

Support plate

The support plate is the support of the billet fixture. The supporting plate is supported on the upper surface of the billet to ensure the smooth operation of the opening and closing mechanism of the billet clamp.

Jaw

The jaws have pin shaft connection type, dovetail connection type, and slot plug type structure. The jaws are the main parts that are in direct contact with the billet, which determines the reliability of the billet clamps.

Applications of lifting clamp

Clamps are widely used in metallurgy, transportation, railway, port, and other industries.

DGMF Mold Clamps Co., Ltd manufactures the mold clamps, and supplies the injection mold components, such as Clamps, Toggle Clamps, C Clamps, Pins, Bushings, Positioning Components, Lock Mold Components, Reset Extrusion, Cavity, and Core Components, Coolings, Die Press Components, Punch And Die, Guide Components, Self-lubricating Components, Springs, Machine Tools, Gate Valves, Machine Mounts, Vises, Fasteners, Lifting, Bolts, Nuts, Washers, etc.

Contact the DGMF Mold Clamps teams for more details about the lifting components such as lifting components specifications, lifting components pricing, lifting components inventory, etc.

Showing all 6 results

-

Heavy-duty Machinist Screw Jacks For Lifting Molds

Read more -

Lifting Eye Nuts DIN 582

Read more -

Lifting Eyebolts Screw Type Lifting Points

Read more -

Lifting shackles Bow Dee and Safety Pin Shackles

Read more -

Swivel Eye Bolt For Lifting

Read more -

Three In One Multi-functional Combination Eyebolt For Lifting

Read more