Mold Clamps

-

ZHUSHI Mold Clamp

Read more -

U-Type Mold Clamps

Read more -

U Mold Clamps For Injection Molding

Read more -

Threaded Rod Extension Nuts

Read more -

Tapped End U-Clamp

Read more -

T Slot Clamps

Read more -

T Slot Bolts

Read more -

T Bolts For Milling Machine

Read more -

T Bolts And Nuts

Read more -

T Bolt Mould Clamp Set

Read more -

Stepped Strap Clamps

Read more -

Step Block Mold Clamps

Read more -

Stamping Die Clamp

Read more -

Quick-Change Mold Clamps

Read more -

Quick-change Arching Mold Clamps

Read more -

Open-Toe Mold Clamps

Read more -

Open Slot Mold Clamp

Read more -

No-Twist Mold Washer

Read more -

Mould Clamps For Injection Moulding

Read more -

Mold Clamps for Injection Molding Machine

Read more -

Mold Clamps For Injection Molding

Read more -

Mold Clamping Stud With Spanner

Read more -

Mold Clamp Washers

Read more -

Mold Clamp M16

Read more -

Mold Clamp Assembly

Read more -

Mold Base Clamp

Read more -

Milling Machine T-Slot Nuts

Read more -

Injection Moulding Die Clamp

Read more -

Injection Mould Clamp

Read more -

Injection Mold Toe Clamps

Read more -

Injection Mold Clamps

Read more -

Hold Down Clamps

Read more -

High-Quality 58pc T-slot Clamping Kit

Read more -

High-Quality 58pc Deluxe Steel Clamping Kit

Read more -

Heavy-duty Mold Clamp

Read more -

Heavy Hex Nuts

Read more -

Gooseneck Mold Clamp

Read more -

Forged U-clamp For Injection Molding

Read more -

Forged U Clamps

Read more -

Forged T Slot Clamps

Read more -

Forged Mould Clamps

Read more -

Forged Mold Clamp For Injection Molding

Read more -

Forged Gooseneck Clamp

Read more -

Forged Goose Neck Mold Clamps

Read more -

Forged Flange Nuts

Read more -

Forged and Hardened Mold Clamping Stud

Read more -

Forged and Hardened Mold Clamp Bolts

Read more -

Extra Long Coupling Nuts

Read more -

Easy Clamps

Read more -

Dongbo High-Quality 58pcs Clamping Sets

Read more -

DIN 508 T Nuts For Milling Machine

Read more -

CNC Wire Stainless Steel EDM Clamps

Read more -

Closed-Toe Mold Clamps

Read more -

Closed End Mold Clamps

Read more -

Clamps for Fixing Mold

Read more -

Clamping Stud Mould Clamp Set

Read more -

C Type Mould Clamp For Injection Moulding

Read more -

Arching Mold Clamps

Read more -

Arching C Type Mold Clamps

Read more -

Adjustable Clamp Universal Mold Clamp

Read more -

58 pcs Steel Clamping Kit

Read more -

12.9 Grade Square Head T Bolt

Read more

Mould Clamps Manufacturer

Mold Clamps Supplier

DGMF Mold Clamps Co., Ltd is the mold clamps supplier and mould clamps manufacturer in China. DGMF Mold Clamps Co., Ltd provides all kinds of mold clamp types and huge mold clamp storage.

What is the mold clamp standard?

There are two processing standards for mold clamps. National Standard Machinery Standard: GB∕T 699-1988. The second type of machinery department standard is JB∕T 8044-1999.

What is a mold clamp?

The mold clamp is a clamping fixture element used to inject model machinery. Its main function is to keep the workpiece from vibrating or moving during the handling process. It ensures the accuracy and good finish of the molded workpiece.

The material used for the mold clamp is 45# medium carbon steel forged as a whole. Through special heat treatment, processing from our company mainly for the processing of various machine processing plants to customize a variety of shaped mold clamps.

The mold clamp is a unique and innovative tool with endless applications in the molding industry.

This mold clamp holds the two parts of the mold together so the casting material stays in the mold until it hardens or cools. By preventing the material from being injected, it prevents the area used for polishing from being damaged or scratched.

This mold clamp is a clamping device that holds the two halves of the casting mold together while pouring and waiting for the liquid to set. After setup, the mold clamp is removed and the two halves can be separated.

During the pouring process, the mold clamps into the mold. The mold clamps help by forming automatic molds during the pouring cycle and allowing each mold to be used over and over again.

The mold clamps also increase automated productivity by programming the clamping mechanism.

Therefore, the quality of the mold clamps directly affects the quality of the molded product. Die clamps play a vital role in the mold manufacturing process. Die clamps offer high strength, small size, flexibility, and simple operation.

What is the manufacturing process of mold clamps?

It is made of 45# medium carbon steel material with a forging press. After high-temperature heating and hammer hammering, the hardness can reach above 30HRC.

Then use a universal milling machine to process the plane and long grooves to achieve a surface finish of 3.2. As well as the parallelism and flatness of the platen, all errors are not more than 0.02MM.

After heat treatment and quenching, it reaches 35HRC to 40HRC required by JB. Finally, the surface is blackened or blued to achieve the purpose of preventing rust spots.

Various machine tools, heavy machine tool mold clamps, and various machine tool processing auxiliary tools. All mold clamps are forged from 45# medium carbon steel. Through special heat treatment, and processing.

DGMF Mold Clamps Co., Ltd’s mold clamps’ features

Made of long-lasting through-hardened steel

Easy to install and adjustable

Complete size

Various style

Quick mold change solution

Competitive price

Large quantity inventory

Made of long-lasting through-hardened steel

Prompt delivery

Reliable quality.

The Mold Support Clamp is used to hold a mold in position on a vertical steel column or angle.

Mold clamps are widely used in any injection molding machine for holding the die part (mold) between the fixed and movable platen. More durable than less expensive, case-hardened clamps.

These clamps can fasten Molds whether they are changed vertically or horizontally.

Attach the clamps on the fixed-platen side to prevent the mold from rotating or the locating ring from disengaging from the alignment hole, but do not yet fully tighten the bolts to the specified torque value.

Properly secure connection Wrong connection.

Adjust the injection pressure, clamp pressure, and the volume of material to be injected (if this feature is available). It all depends on the complexity of your mold and the parts it will make.

Find the correct tonnage of clamp force this mold requires and set it appropriately; do not assume that full clamp force is needed. Sizing And Inspection Before installing a mold, a machine must be selected that is properly sized for the specific mold being installed.

The injection nozzle on the machine must be aligned with the mold cavity. There is also a range of different Die Clamps available to suit your injection molding or mold casting requirements.

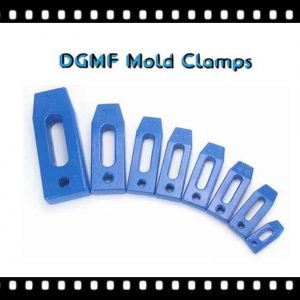

What are the Mold Clamp Types?

Quick-change Arching Mold Clamps

Adjustable Clamp Universal Mold Clamp

Mold Clamps for Injection Molding Machine

Mold Clamps For Injection Molding

Forged Mold Clamp For Injection Molding

U Mold Clamps For Injection Molding

What are the Mold Clamp Bolts and Nuts?

etc

What are the mold clamp assemblies?

etc

What are the mold clamp specifications?

The mold clamp specifications have:

Mold clamp M12

Mold clamp M14

Mold clamp M16

Mold clamp M18

Mold clamp M20

Mold clamp M24

Mold clamp M27

Mold clamp M30

Mold clamp M36

etc

How to Mount an Injection Mold?

DGMF’s Mold Clamps are easy to install and reduce setup time.

Are you setting clamp tonnage based on the mold or the machine?

Remember that to proof your mold, the injection molders have to schedule machine time, dry or otherwise prepare your raw material, and install and set up your mold.

Setting Up A Mold – How to install and set up an injection mold properly. Swivel base adjusting screws come standard with most assemblies.

Often it will not inject all the way, leaving a shortened product or it will inject too much, and plastic can shoot out of the mold. Just because you are running in a 500-ton press doesn’t mean you should be clamping to 500 tons.

You can now use this clamping force to multiply by the total projected area to establish the recommended clamp force for your mold.

Start the machine, make sure the injection sled is in the full-back position, and set the barrel heaters to the proper temperatures.

The mold clamps are machined to fit into the T-slot of the bolster for extra secure positioning.

A 3/4 part of the eyebolt screw enters into holes of mold, and 2 eyebolts are used to secure the transport and personal security.

The flange-mount die clamps can be bolted onto the bolster and the automatic slider model die clamps make the remote automatic operation possible.

You can take a dial indicator reading to see the rise or fall of a tool as it unclamps and clamps, If the moving platen side moves as much as the leader pin clearance when the mold faces kiss, rehang your tool.

The material is then injected into the mold under high pressure. Washers are extra-large and made of hardened steel.

Thread Tools.

Simply bolt the platen plates onto the machine’s platens, install manifolds, place clamps in slots, and connect hoses and you’re ready for production.

DGMF Mold Clamps Co., Ltd manufactures the mold clamps, and supplies the injection mold components, such as Clamps, Toggle Clamps, C Clamps, Pins, Bushings, Positioning Components, Lock Mold Components, Reset Extrusion, Cavity, and Core Components, Coolings, Die Press Components, Punch And Die, Guide Components, Self-lubricating Components, Springs, Machine Tools, gate valves, Machine Mounts, Vises, Fasteners, Lifting, Bolts, Nuts, Washers, etc.

Contact the DGMF Mold Clamps teams for more details about the mold clamps such as mold clamp specifications, mold clamp price, mold clamp inventory, mold clamp types, etc.

Showing 1–16 of 62 results

-

12.9 Grade Square Head T Bolt

Read more -

58 pcs Steel Clamping Kit

Read more -

Adjustable Clamp Universal Mold Clamp

Read more -

Arching C Type Mold Clamps

Read more -

Arching Mold Clamps

Read more -

C Type Mould Clamp For Injection Moulding

Read more -

Clamping Stud Mould Clamp Set

Read more -

Clamps for Fixing Mold

Read more -

Closed End Mold Clamps

Read more -

Closed-Toe Mold Clamps

Read more -

CNC Wire Stainless Steel EDM Clamps

Read more -

DIN 508 T Nuts For Milling Machine

Read more -

Dongbo High-Quality 58pcs Clamping Sets

Read more -

Easy Clamps

Read more -

Extra Long Coupling Nuts

Read more -

Forged and Hardened Mold Clamp Bolts

Read more