Description

Mold Cooling Cascade Water Junctions Cooling Pipes

The injection molding cycle of a product is inseparable from cooling. The effect of water transport makes the size of the product more stable and at the same time improves production efficiency.

The cooling pipe is also called a water junction, the main function of the mold cooling pipe water junction is to cool the mold core from the inside.

We have many types of Mold Cooling Cascade Water Junctions Cooling Pipes as below.

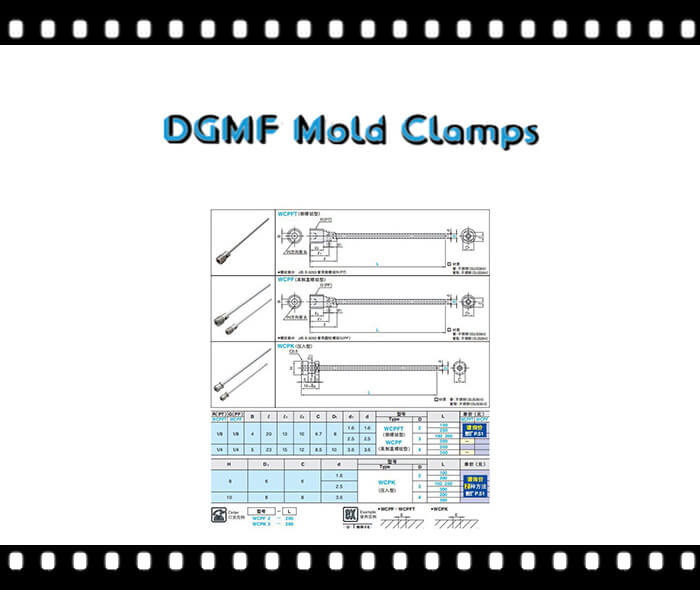

- WCPFT tapered screw-type / taper thread type Cascade Water Junctions Cooling Pipe.

2. WCPFL Parallel pipe thread type Mold Cooling Cascade Water Junctions Cooling Pipes.

Notes on the handling of WCPFT and WCPF cooling pipes water junctions

(1). The threaded part of WCPFT is a tapered pipe thread (R・PT), and the threaded part of WCPF is a parallel pipe thread (G・PF).

(2). The tapered pipe thread and the parallel pipe thread are of the same size and pitch, so be careful when making a screw hole. If you install a tapered pipe thread in a parallel pipe thread hole, water leakage will occur.

Also, note that a parallel pipe thread does not fit into a tapered screw Cascade Water Junctions Cooling Pipe

(3). When using WCPFT and WCPF, use sealing tape.

- WCPKD caulking type Mold Cooling Cascade Water Junctions Cooling Pipe.

4. Spot Cooling Pipes ( SWCP fixed type, SWCT rotary type)

DGMF Mold Clamps Co., Ltd’s Spot Cooling Pipe Water Junctions are ideal for cooling plastics molds and die-cast dies where drilled waterlines through the block are not possible due to interference with the ejector pins, sprue puller pins, etc.

The brass tube has the rigidity to maintain uniform spacing inside the water channel and is threaded into the body for firm support. Waterlines may be connected to the same side or opposite sides of the brass hexagonal body.

Notes on handling

(1). Pipes are a removable type, cut it when necessary.

(2). Note that intermittent or continuous turning of the rotary part of the SWCT could damage the O-ring, which results in water leakage.

(3). Use in atmospheric pressure 980kPa or lower.

(4). Use water and or oil at a temperature of 180℃ or lower.

(5). They may interfere depending upon the size of 2 joints and nipples, etc. to use.

- Spiral Water Junctions Mold Cooling Cascade Water Junctions Cooling Pipes

Material: Aluminum 6061

D: M12 M16 M20 M25 M32 M 40 M50

L: 125mm 150mm 175mm 200mm 250mm 300mm 350mm 400mm

(1). The spiral water core is made of aluminum material, which has good rigidity and temperature resistance.

(2). The design of the thread structure can quickly and evenly control the mold temperature, replacing the shortcomings of insufficient strength and poor temperature resistance of the plastic spiral plug baffles, and it has better strength and temperature control than other types of baffle boards’ ability.

(3). The water inlet and outlet modes can be reprocessed by themselves to ensure reasonable use on various occasions.

(4). Easy to install and disassemble, it is a new standard part of the cooling system.

- Cooling Pipes Fine Thread Type Cascade Water Junctions Cooling Pipe

This style can be brass or stainless steel material Mold Cooling Cascade Water Junctions Cooling Pipes.

D: M3 M4 M5 M6 M8 M10

L: 50mm 100mm 150mm 200mm 250mm 300mm

Mold Cooling Cascade Water Junctions Cooling Pipes drawings and specifications

Reviews

There are no reviews yet.