Description

What is Mold Cooling Component Baffle Board?

Baffle board also called plug baffle, has many styles such as straight plug baffles, and spiral plug baffles, with stainless steel, brass, or aluminum materials. The baffle board is the mold interior cooling component for cooling down the water.

Baffle Boards Types – The Mold Interior Cooling Components

Z9661 Type Straight plug baffles

Straight plug baffles drawing

Mold Cooling Components Z9661 straight baffle board specifications

| Model | Width(mm) | Thick(mm) | Length(M) | Material |

| DGMF-MOLD-CLAMP-Z9661/M8*0.75-100 | 6 | 1.6 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/M8*0.75-200 | 6 | 1.6 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/M10*1-100 | 8 | 1.6 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/M10*1-200 | 8 | 1.6 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/M12*1.5-150 | 10 | 2.4 | 150 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/M12*1.5-200 | 10 | 2.4 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/M14*1.5-150 | 12 | 2.4 | 150 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/M14*1.5-200 | 12 | 2.4 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/M16*1.5-150 | 14 | 2.4 | 150 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/M16*1.5-200 | 14 | 2.4 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/G1/8-100 | 8.5 | 1.6 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/G1/8-200 | 8.5 | 1.6 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/G1/4-120 | 11.5 | 2.4 | 120 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/G1/4-250 | 11.5 | 2.4 | 250 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/G3/8-150 | 15 | 2.4 | 150 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9661/G3/8-300 | 15 | 2.4 | 300 | C3604 Brass |

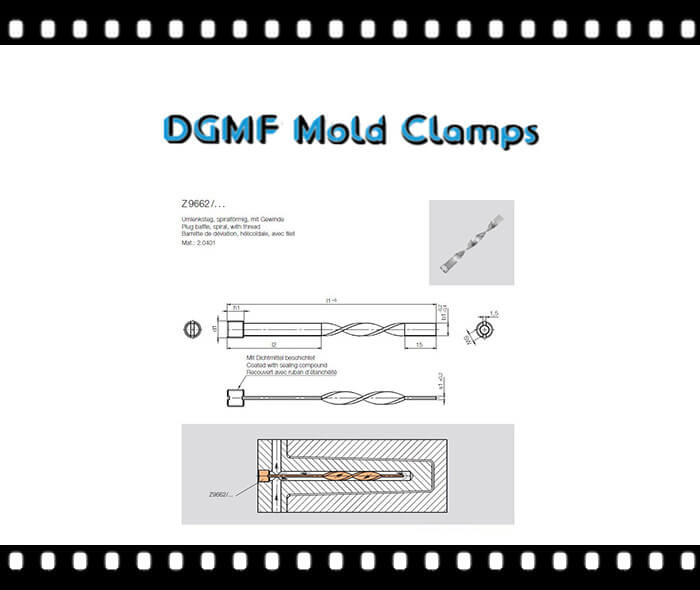

Z9662 Type Spiral plug baffles

Spiral plug baffles drawing

Mold Cooling Z9662 spiral plug baffle specifications

| Model | Width(mm) | Thick(mm) | Length(M) | Material |

| DGMF-MOLD-CLAMP-Z9662/M8-100 | 6 | 1.6 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/M10-100 | 8 | 1.6 | 150 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/M12-125 | 10 | 2.4 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/M14-150 | 12 | 2.4 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/M16-150 | 14 | 2.4 | 150 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/G1/8-100 | 8.5 | 1.6 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/G1/8-200 | 8.5 | 1.6 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/G1/4-125 | 11.5 | 2.4 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/G1/4-250 | 11.5 | 2.4 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/G3/8-150 | 15 | 2.4 | 150 | C3604 Brass |

| DGMF-MOLD-CLAMP-Z9662/G3/8-300 | 15 | 2.4 | 200 | C3604 Brass |

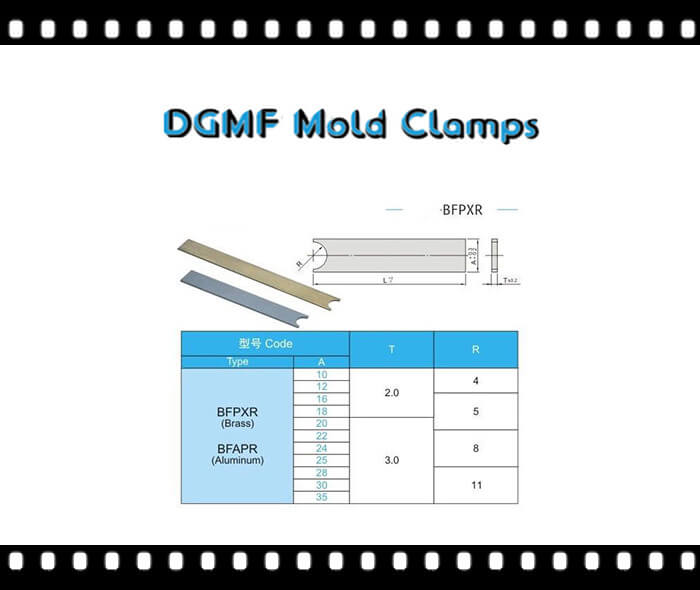

BFPXR Type Flat plug baffles

| Model | Width(mm) | Thick(mm) | Length(M) | Material |

| DGMF-MOLD-CLAMP-BFPXR10-100 | 10 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXR12-100 | 12 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXR16-100 | 16 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXR18-100 | 18 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXR20-100 | 20 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXR22-100 | 22 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXR24-100 | 24 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXR25-100 | 25 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFAPR10-100 | 10 | 2 | 100 | A5052P Aluminum |

| DGMF-MOLD-CLAMP-BFAPR12-100 | 12 | 2 | 100 | A5052P Aluminum |

| DGMF-MOLD-CLAMP-BFAPR16-100 | 16 | 2 | 100 | A5052P Aluminum |

| DGMF-MOLD-CLAMP-BFAPR18-100 | 18 | 2 | 100 | A5052P Aluminum |

| DGMF-MOLD-CLAMP-BFAPR20-100 | 20 | 2 | 100 | A5052P Aluminum |

| DGMF-MOLD-CLAMP-BFAPR22-100 | 22 | 2 | 100 | A5052P Aluminum |

Flat plug baffles drawing

| Model | Width(mm) | Thick(mm) | Length(M) | Material |

| DGMF-MOLD-CLAMP-BFPXG10-100 | 10 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXG12-100 | 12 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXG16-100 | 16 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXG18-100 | 18 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXG20-100 | 20 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-BFPXG22-100 | 22 | 2 | 100 | C3604 Brass |

The mold baffle board is generally installed in the mold with a long protrusion inside the core. It should be that the core is not allowed to drill on the outer surface. Only one hole can be drilled at the bottom, and then separated by a beryllium copper sheet to form a water transport circuit. To achieve the cooling effect.

The mold baffle board can be installed quickly to reduce the time of up and down the mold, establish a failure mode and impact analysis library, and prevent water.

Baffle boards are generally not used in the mold cooling water path, but if the cooling water path is a single bottom-up water inlet and outlet, it is required to install 1 to 2 upward cooling baffle boards in the same port or the same straight water path.

Quality inspection problem

- Establish the processing technology for the mold water barrier, and summarize the mold parts list, purchased parts list, standard parts list, self-made parts list, self-made standard parts list, material list, heat treatment parts list, The list of wearing parts and mold costs, to ensure that relevant resources can be in place in time.

- Combine production plan management and schedule management to ensure that relevant equipment can be used effectively, prevent personnel from being idle, and enable all links in processing and manufacturing to be linked together.

- Establish a failure mode and impact analysis library: Establish a mold design, manufacturing failure mode, and impact analysis library, and prevent the same problem from appearing next time through meetings, announcements, computer sharing, plus rewards and penalties.

Advantage

- Quick installation, reduces the time of up and down molds and improves work efficiency.

- Uniform water flow to ensure product quality and efficiency of injection molding, die-casting, and blow molding.

- Price advantage and quality assurance to improve competitiveness.

| Model | Width(mm) | Thick(mm) | Length(M) | Material |

| DGMF-MOLD-CLAMP-M8-50(粗牙) | 8 | 2 | 50 | C3604 Brass |

| DGMF-MOLD-CLAMP-M8-100(粗牙) | 8 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-M8-200(粗牙) | 8 | 2 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-M8-300(粗牙) | 8 | 2 | 300 | C3604 Brass |

| DGMF-MOLD-CLAMP-M10-50(粗牙) | 10 | 2 | 50 | C3604 Brass |

| DGMF-MOLD-CLAMP-M10-100(粗牙) | 10 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-M10-200(粗牙) | 10 | 2 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-M10-300(粗牙) | 10 | 2 | 300 | C3604 Brass |

| DGMF-MOLD-CLAMP-M12-50(粗牙) | 12 | 2 | 50 | C3604 Brass |

| DGMF-MOLD-CLAMP-M12-100(粗牙) | 12 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-M12-200(粗牙) | 12 | 2 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-M12-300(粗牙) | 12 | 2 | 300 | C3604 Brass |

| DGMF-MOLD-CLAMP-M14-50(粗牙) | 14 | 2 | 50 | C3604 Brass |

| DGMF-MOLD-CLAMP-M14-100(粗牙) | 14 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-M14-200(粗牙) | 14 | 2 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-M14-300(粗牙) | 14 | 2 | 300 | C3604 Brass |

| DGMF-MOLD-CLAMP-M16-50(粗牙) | 16 | 2 | 50 | C3604 Brass |

| DGMF-MOLD-CLAMP-M16-100(粗牙) | 16 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-M16-200(粗牙) | 16 | 2 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-M16-300(粗牙) | 16 | 2 | 300 | C3604 Brass |

| DGMF-MOLD-CLAMP-M18-50(粗牙) | 18 | 2 | 50 | C3604 Brass |

| DGMF-MOLD-CLAMP-M18-100(粗牙) | 18 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-M18-200(粗牙) | 18 | 2 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-M18-300(粗牙) | 18 | 2 | 300 | C3604 Brass |

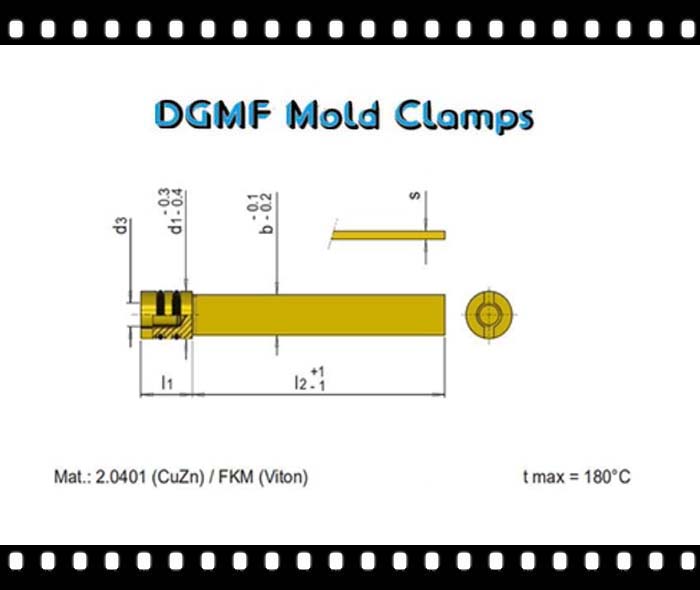

Baffle board with O-ring Descriptions:

When making molds, it is necessary to design a water circuit to reduce the temperature during mold production, shorten the forming cycle, and improve the quality of the product.

Since the core can not be drilled on the outer surface but has to be cooled to reach the water circulation, so can only be drilled at the bottom, and then separated by a beryllium copper sheet, to make a circulating water circuit.

Therefore, the baffle board is usually used in the raised part of the mold core or the long core part which the water circuit cannot reach, and the water holes where the baffle board is installed are often called water wells.

By installing the baffle board, the water well will be divided into two to form a water path, through the water circuit of the mold, so that the water can be transported normally to take away the heat of the mold and play the role of rapid cooling of the mold.

This baffle board is O-ring sealed, by squeezing the O-ring, to achieve the sealing effect, but also play the role of the plug sealing water.

| Baffle Board With O-ring Specifications | |||||

| Model | Screw Size/ d3 | Head length/ l1(mm) | Head ID/ d1(mm) | Board width/ d(mm) | Board length/ l2(mm) |

| DGMF-MOLD-CLAMP-STBB-06140 | M3 | 13 | 8 | 6 | 140 |

| DGMF-MOLD-CLAMP-STBB-08180 | M5 | 13 | 10 | 8 | 180 |

| DGMF-MOLD-CLAMP-STBB-10180 | M6 | 13 | 12 | 10 | 180 |

| DGMF-MOLD-CLAMP-STBB-12220 | M6 | 16 | 14 | 12 | 220 |

| DGMF-MOLD-CLAMP-STBB-15250 | M8 | 16 | 16 | 15 | 250 |

| DGMF-MOLD-CLAMP-STBB-16250 | M8 | 16 | 18 | 16 | 250 |

| DGMF-MOLD-CLAMP-STBB-18300 | M10 | 20 | 20 | 18 | 300 |

| DGMF-MOLD-CLAMP-STBB-20300 | M12 | 20 | 22 | 20 | 300 |

| DGMF-MOLD-CLAMP-STBB-25390 | M16 | 22 | 26 | 25 | 390 |

| Model | Width(mm) | Thick(mm) | Length(M) | Material | Type |

| DGMF-MOLD-CLAMP-BFPT-S18-100 | 18 | 2 | 100 | SS | Single-side |

| DGMF-MOLD-CLAMP-BFPT-W18-100 | 18 | 2 | 100 | SS | Double-side |

| DGMF-MOLD-CLAMP-BFPT-S20-100 | 20 | 2 | 100 | SS | Single-side |

| DGMF-MOLD-CLAMP-BFPT-W20-100 | 20 | 2 | 100 | SS | Double-side |

| DGMF-MOLD-CLAMP-BFPT-S24-100 | 20 | 2 | 100 | SS | Single-side |

| DGMF-MOLD-CLAMP-BFPT-W24-100 | 20 | 2 | 100 | SS | Double-side |

| DGMF-MOLD-CLAMP-BFPT-S30-100 | 30 | 2 | 100 | SS | Single-side |

| DGMF-MOLD-CLAMP-BFPT-W30-100 | 30 | 2 | 100 | SS | Double-side |

| Model | Spec | Width(mm) | Thick(mm) | Length(M) | Material |

| DGMF-MOLD-CLAMP-ES-01-100 | 1/8 PT | 8.2 | 2 | 100 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-01-200 | 1/8 PT | 8.2 | 2 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-02-150 | 1/4 PT | 11.2 | 2.5 | 150 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-02-250 | 1/4 PT | 11.2 | 2.5 | 250 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-03-150 | 3/8 PT | 14.7 | 2.5 | 150 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-03-300 | 3/8 PT | 14.7 | 2.5 | 300 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-04-200 | 1/2 PT | 18.2 | 2.5 | 200 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-04-400 | 1/2 PT | 18.2 | 2.5 | 400 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-06-300 | 3/4 PT | 23.2 | 3 | 300 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-06-500 | 3/4 PT | 23.2 | 3 | 500 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-08-400 | 1 PT | 26.7 | 3 | 400 | C3604 Brass |

| DGMF-MOLD-CLAMP-ES-08-600 | 1 PT | 26.7 | 3 | 600 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-01-4 | 1/8 NPT | 5/16 | 1/16 | 4 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-01-8 | 1/8 NPT | 5/16 | 1/16 | 8 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-02-8 | 1/4 NPT | 7/16 | 3/32 | 8 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-02-10 | 1/4 NPT | 7/16 | 3/32 | 10 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-03-6 | 3/8 NPT | 9/16 | 3/32 | 6 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-03-12 | 3/8 NPT | 9/16 | 3/32 | 12 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-04-8 | 1/2 NPT | 11/16 | 3/32 | 8 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-04-16 | 1/2 NPT | 11/16 | 3/32 | 16 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-06-12 | 3/4 NPT | 15/16 | 1/8 | 12 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-06-20 | 3/4 NPT | 15/16 | 1/8 | 20 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-08-16 | 1 NPT | 1 1/8 | 1/8 | 16 | C3604 Brass |

| DGMF-MOLD-CLAMP-AS-08-24 | 1 NPT | 1 1/8 | 1/8 | 24 | C3604 Brass |

This product is a water trap -basic, the main feature is that it is not good to open the water circuit in the core and other places, or other places where only one direction can open the water circuit so that putting in the water trap, you can achieve one in and one out, to carry out the water circuit, and then to achieve the cooling effect of the mold.

There are mainly two kinds of materials:

Material Brass (C3604)

Material Aluminium (A5052P)

| Model | Size | Width(mm) | Thick(mm) | Length(M) | Material |

| DGMF-MOLD-CLAMP-BBAL-08212 | 8*2*1.2 | 8 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-10212 | 10*2*1.2 | 10 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-12212 | 12*2*1.2 | 12 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-14212 | 14*2*1.2 | 14 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-15212 | 15*2*1.2 | 15 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-16212 | 16*2*1.2 | 16 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-18212 | 18*2*1.2 | 18 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-20212 | 20*2*1.2 | 20 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-22212 | 22*2*1.2 | 22 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-24212 | 24*2*1.2 | 24 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-25212 | 25*2*1.2 | 25 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-26212 | 26*2*1.2 | 26 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-28212 | 28*2*1.2 | 28 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-30212 | 30*2*1.2 | 30 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-35212 | 35*2*1.2 | 35 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-40212 | 40*2*1.2 | 40 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBAL-50212 | 50*2*1.2 | 50 | 2 | 1.2 | Aluminum |

| DGMF-MOLD-CLAMP-BBCU-0821 | 8*2*1 | 8 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-1021 | 10*2*1 | 10 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-1221 | 12*2*1 | 12 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-1421 | 14*2*1 | 14 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-1521 | 15*2*1 | 15 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-1621 | 16*2*1 | 16 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-1821 | 18*2*1 | 18 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-2021 | 20*2*1 | 20 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-2221 | 22*2*1 | 22 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-2421 | 24*2*1 | 24 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-2521 | 25*2*1 | 25 | 2 | 1 | Brass |

| DGMF-MOLD-CLAMP-BBCU-3021 | 30*2*1 | 30 | 2 | 1 | Brass |

Stainless Steel Material Baffle Board with Screw Mount Type Product Overview

This product is a stainless steel water trap-threaded installation type, the main feature is that in the core and another bad open water circuit, or only one direction can open the water circuit of the place, so into the water trap, you can achieve one in one out, water circulation, and thus achieve the cooling effect of the mold.

This product is simple and convenient to install, the material is stainless steel (SUS304), with corrosion resistance, a water trap plate, and a PT thread shoulder made of whole, which is easy to maintain.

Stainless Steel Material Baffle Board with Screw Mount Type Product Features

1. Convenient disassembly, easy-to-follow-up replacement, and management, saving labor costs.

2. Saving mold space, can be used where the conventional water circuit can not reach, good local cooling effect.

3. Extend the life of the mold, improve the yield rate, and achieve automated production.

Stainless Steel Material Baffle Board with Screw Mount Type Specifications

| Model | Width(mm) | Thick(mm) | Length(M) | Material |

| DGMF-MOLD-CLAMP-BFPTS 8-100 | 8 | 2 | 100 | SS |

| DGMF-MOLD-CLAMP-BFPTS 10-100 | 10 | 2 | 100 | SS |

| DGMF-MOLD-CLAMP-BFPTS 12-100 | 12 | 2 | 100 | SS |

| DGMF-MOLD-CLAMP-BFPTS 14-100 | 14 | 2 | 100 | SS |

| DGMF-MOLD-CLAMP-BFPTS 18-100 | 18 | 2 | 100 | SS |

| DGMF-MOLD-CLAMP-BFPTS 18-150 | 18 | 2 | 150 | SS |

| DGMF-MOLD-CLAMP-BFPTS 18-200 | 18 | 2 | 200 | SS |

| DGMF-MOLD-CLAMP-BFPTS 18-300 | 18 | 2 | 300 | SS |

| DGMF-MOLD-CLAMP-BFPTS 20-100 | 20 | 2 | 100 | SS |

| DGMF-MOLD-CLAMP-BFPTS 20-150 | 20 | 2 | 150 | SS |

| DGMF-MOLD-CLAMP-BFPTS 20-200 | 20 | 2 | 200 | SS |

| DGMF-MOLD-CLAMP-BFPTS 20-300 | 20 | 2 | 300 | SS |

| DGMF-MOLD-CLAMP-BFPTS 24-100 | 24 | 2 | 100 | SS |

| DGMF-MOLD-CLAMP-BFPTS 24-150 | 24 | 2 | 150 | SS |

| DGMF-MOLD-CLAMP-BFPTS 24-200 | 24 | 2 | 200 | SS |

| DGMF-MOLD-CLAMP-BFPTS 24-300 | 24 | 2 | 300 | SS |

| DGMF-MOLD-CLAMP-BFPTS 30-100 | 30 | 2 | 100 | SS |

| DGMF-MOLD-CLAMP-BFPTS 30-150 | 30 | 2 | 150 | SS |

| DGMF-MOLD-CLAMP-BFPTS 30-200 | 30 | 2 | 200 | SS |

| DGMF-MOLD-CLAMP-BFPTS 30-300 | 30 | 2 | 300 | SS |

Reviews

There are no reviews yet.