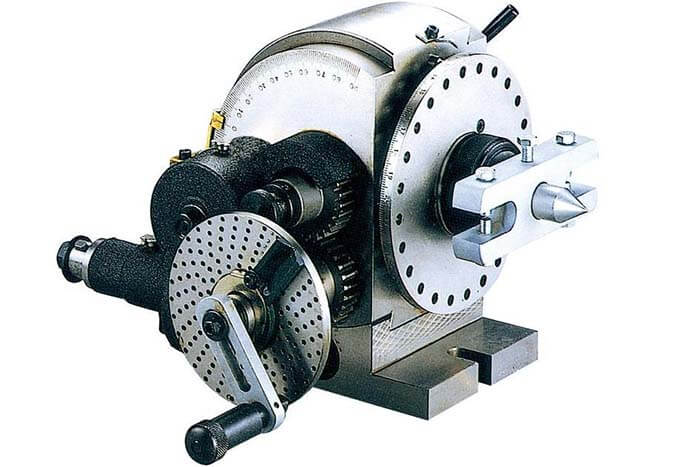

An indexing head, also known as a dividing head or spiral head, is a specialized tool that allows a workpiece to be circularly indexed.

The indexing dividing head for the milling machine is a machine tool accessory installed on the milling machine to divide the workpiece into arbitrary parts.

What are the applications of the indexing head?

A machine tool accessory that holds the workpiece in a chuck or with a center and a dial and makes it rotate and index. The indexing dividing head is mainly used in milling machines, but also commonly used in drilling machines and surface grinders, and can be placed on the platform for the clampers to scribe. The indexing dividing head mainly has two types available indexing head and optical indexing head.

What are the structural classifications of indexing heads?

According to its transmission and indexing form, it can be divided into worm gear sub-indexing head, dial indexing head, hole disc indexing head, slotted disc indexing head, end gear disc indexing head, and other indexing heads (including inductive indexing head and grating indexing head).

According to its function, it can be divided into a universal dividing head, semi-universal dividing head, and equal indexing dividing head.

According to its structure, there are vertical and horizontal indexing dividing heads, tiltable indexing dividing heads, and overhanging beam indexing dividing heads. The structure of the indexing dividing head is mainly composed of the clamping part, indexing and positioning part, and transmission part.

General

The general indexing method and functions can be divided into 3 kinds.

Universal dividing head

What is a universal dividing head?

The universal dividing head is the most widely used. The spindle can be tilted at any angle between horizontal and vertical directions. The indexing mechanism consists of an indexing disc and a worm-worm-wheel pair with a transmission ratio of 1:40 (see worm drive), and the indexing disc has multiple positioning holes with different equal parts. The indexing can be realized by turning the handle connected to the worm to insert the locating pin into the selected locating hole.

When the number of equal indexing holes on the indexing disc cannot meet the indexing requirements, the transmission ratio can be changed through the exchange gear between the worm wheel and the spindle to expand the indexing range.

On the milling machine, the exchange gear of the universal dividing head can be connected with the feed screw of the milling machine table, so that the axial feed and rotary movement of the workpiece can be combined to mill the spiral groove according to a certain guide.

Semi-universal indexing head

What is Semi-universal indexing head?

The structure is basically the same as the universal indexing head, but without the exchange gear mechanism, can only use the indexing disc to index directly, and cannot be linked with the milling machine table.

Equal indexing head

What is Equal indexing head?

Generally adopt 24 slots or holes of equal indexing plate, directly realize 2, 3, 4, 6, 8, 12, 24 equal indexing, there are 3 kinds of horizontal, vertical and vertical. The horizontal base has two vertical mounting surfaces, and the spindle can be in a horizontal or vertical position. The indexing accuracy of the general-purpose indexing head is generally ±60″.

Optical

The spindle is equipped with a precision glass dial or angle grating, subdivided and magnified by an optical or photoelectric system. Then the angle value is read out by the eyepiece, light screen, or digital display device. The indexing accuracy can reach ±1″, and the optical indexing head is used for precision machining and angle measurement.

CNC

CNC indexing head is driven by AC or DC server motor, driven by compound pitch worm gear set mechanism, using a hydraulic ring locking device, plus solid rigid sealing structure.

The CNC indexing head is widely used in milling machines, drilling machines, and machining centers. With the four-axis interface of the workhorse, it can be used for simultaneous four-axis machining.

The CNC indexing head can be combined with a spark machine for the machining of pedal car and automobile tire molds.

The CNC indexing head can also be combined with DC/AC single-axis servo controller and connected to M-signal for equal division processing.

What are the functions of the indexing head?

1) To index the workpiece around its own axis (equally or unequally). Such as hexagons, gears, splines, and other divided parts.

2) To make the axis of the workpiece relative to the milling machine table into the required angle (horizontal, vertical, or inclined). Therefore, it is possible to machine beveled surfaces at different angles.

3) When milling spiral grooves or cams, it can make the workpiece rotate continuously with the movement of the table.

What are the indexing methods?

For example, indexing z=35, the number of revolutions of the handle for each indexing is: n=40/z=40/35=1 and 1/7, i.e. for each indexing, the handle needs to turn 1 and 1/7 revolutions.

This 1/7th turn is controlled by the indexing discs, and generally, the indexing head is equipped with two discs. There are many holes on both sides of the indexing disc, the number of holes in each circle is not equal, but the distance between holes in the same circle is equal.

The number of holes on the front side of the first indexing disc is 24, 25, 28, 30, 34, 37; the reverse side is 38, 39, 41, 42, 43.

The second indexing disc has 46, 47, 49, 51, 53, and 54 holes on the front side and 57, 58, 59, 62, and 66 holes on the backside.

When simple indexing, the indexing disc is fixed. At this time, the indexing plate will be pulled out of the positioning pin, adjusting the number of holes for the number of times 7 on the hole circle, that is, 28, 42, 49 can be.

If you choose the number of 42 holes, that is 1/7 = 6/42.

Therefore, when indexing, the handle turns through a turn, and then along the number of 42 holes on the hole circle turned through 6 hole spacing.

In order to avoid the trouble of counting holes each time and to ensure that the number of holes turned by the handle is reliable, the angle between the two fractal clamps on the indexing plate can be adjusted so that it is equal to the number of hole spacing to be divided so that the indexing can be done accurately in turn.

What are the differences between indexing discs and indexing heads?

Indexing discs have been widely used in packaging, electronic and electrical appliances, glass and ceramics, printing, pharmaceutical, chemical, tobacco, automobile manufacturing, and other automated production lines and various general mechanical equipment, which play a vital role as the core transmission device of automated machines.

Many people often think that the indexing disc and indexing head are the same kinds of objects, now I will tell you where the difference between the indexing disc and indexing head is reflected.

What is an indexing disc?

The indexing disc is also known as cam indexer, intermittent divider, arc indexing disc, parallel indexing disc, etc. Through this mechanism, the continuous input motion can be transformed into intermittent indexing motion.

The rotation ratio of the indexing disc is 1:90. The principle is the same as that of the indexing head, which is hand-cranked for 90 turns, then the indexing flies through one turn.

Normally, for every 360° rotation of the input axis, the output axis completes an indexing motion (stationary and indexing) at the same time. During an indexing motion, the ratio of the time the force take-off axis runs to a standstill is determined by the drive angle of the cam.

The cam drive angle is the angle of rotation required for the incoming cam to drive the indexing of the outgoing force axis. The indexing head is a machine tool accessory installed on the milling machine to divide the workpiece into a given number of parts, and the indexing head has a rotation ratio of 1:40, which means that one rotation of the indexing head requires 40 hand cranks.

The indexing ring and vernier, the locating pins and indexing discs, and the interchangeable gears are used to divide the workpiece mounted between the tips or chucks into given angles and to divide the circumference into given parts to assist the machine tool in the machining of various grooves, spur gears, helical spur gears, Archimedes screw cams, etc. using various different shaped tools.

Besides this article, you may also be interested in the below articles.

Extrusion vs. Injection Molding, What Is The Difference?

Injection Molding vs. Thermoforming, What’s the Difference?

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

What Is The Difference Between Two-Platen Mold And Three-Platen Mold?