A permanent magnetic chuck, also known as a magnetic chuck, is a magnetic fixture widely used in machine shops, mold factories, and other machining fields, which can greatly improve the clamping efficiency of magnetic steel materials.

Permanent magnetic chucks are modern devices replacing vices, mechanical clamps, and fixtures. Using electromagnetic, electro-permanent, and permanent magnetic chucks for clamping and unclamping the machined components saves time, allows the workpiece to be accessible from 5 sides, and does not damage the product.

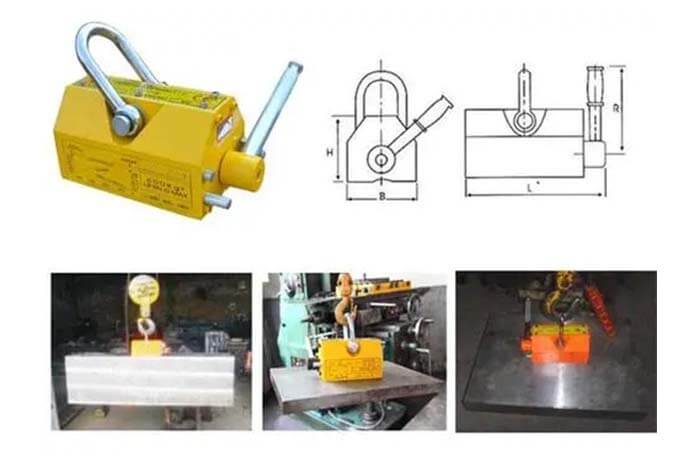

A permanent magnetic chuck is based on high-performance rare earth material NdFeB (N>40) as the core, by hand-triggered chuck handle rotation, so as to change the magnetic system of NdFeB inside the chuck, to achieve the suction or release of the processed workpiece.

In the machining and mold-making industries, we used to use a vise or press the platen directly on the workbench to clamp the workpiece, which wasted a lot of precious processing time and low efficiency.

With the emergence of high-performance NdFeB rare earth materials, the development of magnetic clamping using NdFeB permanent magnet materials has become a trend, and the permanent magnetic chuck was born.

What is the application of a permanent magnetic chuck?

A permanent magnetic chuck is designed by using the principle of continuity of magnetic flux and the principle of superposition of magnetic field. The magnetic circuit of the permanent magnetic chuck is designed into multiple magnetic systems, and through the relative movement of the magnetic systems, the magnetic field strength on the working pole is added or eliminated, so as to achieve the purpose of suction and unloading.

What are the characteristics of a permanent magnetic chuck?

1) Permanent magnetic chuck adopts high-performance permanent magnetic material Nd-Fe-B as the core of the product, which makes the product smaller in size and stronger in lifting and hoisting force, and the magnetic force is permanent.

2) Permanent magnetic chuck can be used without electricity, saving the trouble power supply.

3) Permanent magnetic chuck Optimized magnetic circuit design so that the remanent magnetism is almost zero.

4) Permanent magnetic suction cups Professional design and appearance make the product more beautiful.

How to use the permanent magnetic chuck?

Place the workpiece on the magnetic chuck table, and then insert the wrench into the shaft hole to suck the workpiece ready for processing.

To prevent any possible accidental rotation of the wrench in the magnetized state, the wrench should be removed before machining.

When the workpiece is finished, insert the wrench into the shaft hole and turn it 180 to “OFF” counterclockwise to finish demagnetization and remove the workpiece safely.

How to design a permanent magnetic chuck?

When designing a permanent magnetic chuck, first of all, the magnetic circuit should be designed carefully, a good magnetic circuit structure can make as much magnetic flux gather in the working surface as possible to meet the requirements of lifting weight, and it can use less NdFeB material as possible.

At the same time, the design of the magnetic circuit should also be carefully considered when the operator is easier to achieve work unloading. Solve the technical difficulties of permanent magnetic suction cups such as great suction force and difficulty in wrenching the handle.

The magnetic circuit of a permanent magnetic chuck is designed with 2 magnetic systems, which are divided into two parts: active and fixed. Change the state of the active magnetic system, so that the working pole surface is in the state of magnetic field superposition or reverse magnetic field generation, respectively, and the magnetic field is offset.

Meanwhile, in the permanent magnet circuit, some soft magnetic materials are used as magnetic yoke in order to reduce the magnetic resistance and increase the magnetic flux density in the key part of the working pole surface.

How to maintain the permanent magnetic chuck?

- The surface should be wiped clean before using the chuck to avoid scratching and affecting the accuracy.

- Use the environment temperature at -40C–50C, knocking is strictly prohibited to prevent the magnetic force from decreasing.

- After use, apply anti-rust oil on the working surface to prevent rusting.

Besides this What Is A Permanent Magnetic Chuck article, you may also be interested in the below articles?

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept