After the read of Extrusion vs. Injection Molding, What Is The Difference, you will know:

Extrusion vs. Injection Molding Principle

Extrusion vs. Injection Molding Process

Extrusion vs. Injection Molding Time

Extrusion vs. Injection Molding Methods

Extrusion vs. Injection Molding Features

Extrusion vs. Injection Molding Materials

Extrusion vs. Injection Molding Advantages and Disadvantages

Extrusion vs. Injection Molding Product Applications

Extrusion vs. Injection Molding Machine

Extrusion vs. injection molding, What is the difference between extrusion and injection molding?

Extrusion and injection molding are just two methods of plastic processing. Injection molding is suitable for three-dimensional product manufacturing whereas extrusion molding is only suitable for two-dimensional product manufacturing.

Extrusion is mainly used to produce plates, tubes, rods, shaped materials, films, and other materials that can be produced continuously. In contrast, the injection molding process can only be produced intermittently, one mold at a time, beating the product.

Extrusion vs. Injection Molding Principle

What is injection molding?

The injection molding machine uses the nature of plastic to melt into a liquid when heated to a certain temperature, injects the molten liquid into the closed cavity with high pressure, cools and sets the mold, then opens the mold and ejects to get the desired plastic product.

What is extrusion molding?

Extrusion molding is also known as extrusion in plastic processing, in which the pressure of the hydraulic press is used to press out the die itself. It is a processing method in which the material is thermoplasticized by the action between the extruder barrel and the screw while being pushed forward by the screw, and is continuously pushed through the head to make various cross-sectional products or semi-products.

Extrusion mainly refers to the extrusion of the screw or plunger, so that the heat-melted polymer material is forced through the head die under pressure and formed into a continuous profile with a constant cross-section. The extrusion process mainly includes the processes of material addition, melt plasticization, extrusion, shaping, and cooling.

Extrusion vs. Injection Molding Process

Injection molding process:

Injection molding is to feed granular or powdered plastic from the hopper of the injection molding machine into the machine brief after heating and melting plasticization, under the pressure of a plunger or screw, the material is compressed and moved forward, through the nozzle at the front of the machine brief, injected into the closed mold with the low temperature at a very fast speed, after a certain time of cooling and shaping, open the mold to get the product. This molding method is an intermittent operation process.

Extrusion molding process:

The extrusion process can be divided into two stages.

The first stage involves plasticizing the solid plastic (i.e., turning it into a viscous fluid) and passing it under pressure through a specially shaped mouth die into a continuous body with a cross-section similar to the shape of the mouth die.

The second stage is to make the extruded continuum lose its plastic state and turn into a solid, i.e., the desired product, by an appropriate method.

Extrusion vs. Injection Molding Time

The cycle time of injection molding varies from a few seconds to a few minutes. The length of the cycle depends on the wall thickness, size, and shape of the product, the type of injection molding machine, as well as the type of plastic used, and the process conditions.

Plastic extruders go through three stages in the extrusion of plastics, namely, plasticization of raw materials, molding, and cooling. The length of the cycle depends on the wall thickness, size and shape of the product, the type of extruder, the variety of plastics used, and the process conditions.

Extrusion vs. Injection Molding Methods

Injection molding methods

Injection molding can be divided into the injection molding method and die-casting method. An injection molding machine, referred to as an injection molding machine or injection molding machine, is the main molding equipment for making thermoplastic or thermosetting materials into various shapes of plastic products using plastic molding molds, injection molding is achieved through injection molding machine and molds.

Injection molding is mostly used for thermoplastics. It is similar to extrusion molding, except that the molten plastic enters the closed mold through the nozzle, and the product is formed by solidifying inside the mold.

Extrusion molding methods

Extrusion molding is where the plastic is pushed out and out of the extrusion (die) section. A typical product is vinyl chloride pipe. This type of mold is a type of die that has various cross-sectional shapes, such as round and square, depending on the shape of the product.

Extrusion vs. Injection Molding Features

Features of injection molding:

Short production cycle and high production efficiency;

Capable of molding products with complex shapes, precise dimensions, or inserts;

Wide variety of plastics to be molded;

Easy to automate.

Features of extrusion molding:

Continuous, high efficiency, stable quality

Wide range of applications

Simple equipment, low investment, fast results

Hygienic production environment, low labor intensity

Suitable for mass production

Extrusion vs. Injection Molding Materials

Suitable raw materials for injection molding as the below:

Except for a few thermoplastics, almost all thermoplastics can be molded by this method. Injection molding can also process some thermosetting plastics, such as phenolic plastics, etc.

Suitable resin materials for extrusion molding as the below:

Most thermoplastics and thermosets, such as PVC, PS, ABS, PC, PE, PP, PA acrylic resins, epoxy resins, and mylar resins, etc.

What is the difference between extrusion and injection molding materials?

There are 3 main differences between extrusion and injection molding materials.

Difference in liquidity

Injection molding requires high fluidity, especially for thin-walled products and large products. Extrusion is more relaxed because extrusion is open and there is no huge resistance to die reversal.

Melt strength

Injection molding is molded in the mold, there are geometric limitations of the mold composition, and the melt strength requirements are not high. Although extrusion molding also has the geometric limitation of the mouth die, it is not fully cured after the exit of the die, and in this free state, it is sometimes not well formed due to the low melt strength, such as spinning.

In addition, after extrusion is often accompanied by subsequent free-state processing molding, such as thermoforming, and hollow blow molding, in these molding processes there are often different degrees of melt stretching, if the melt strength is low, it is easy to pull through. Therefore, injection molding generally does not require high melt strength, while extrusion is generally required.

Outlet expansion

Injection molding generally does not have strict requirements for exit expansion. Extrusion has a nasty exit expansion. Therefore, the control of viscoelasticity of injection molding and extrusion materials will be different.

Extrusion vs. Injection Molding Advantages and Disadvantages

Injection molding Advantages and Disadvantages

Can injection mold various plastic products with complex shapes?

Products with more accurate structural dimensions and better surface quality.

Injection-molded products can be standardized, standardized, and serialized.

Simple operation, easy adjustment and update of molding molds, fully automatic production, and high production efficiency.

investment in injection molding equipment is relatively large, mold manufacturing costs are high, and product molding process conditions need to be strictly controlled.

Short production cycle and high production efficiency.

Extrusion molding Advantages and Disadvantages

A continuous production process can extrude plastic parts of any length, with high production efficiency.

The structure of mold is also simple, easy to manufacture and maintain, with low investment and a fast payoff.

The internal organization of plastic parts is balanced and tight, and the dimensions are more stable and accurate.

Strong adaptability, except for fluorine plastics, all thermoplastics can be extruded, and some thermosetting plastics can also be extruded. The shape and size of the cross-section of the product can be changed accordingly by changing the head and mouth die so that various plastic parts with different specifications can be produced.

Wide range of applications, simple operation equipment, low investment, fast results, hygienic production environment, low labor intensity, and suitable for mass production.

Extrusion vs. Injection Molding Product Applications

Injection molding product applications :

Injection molding can produce products of various shapes, sizes, and precision to meet various requirements.

The weight of injection molded products ranges from one gram to tens of kilograms, depending on the need.

Extrusion molding product applications:

Plastic films, nets, products with cladding, tubes, plates, sheets, rods, packing tapes, monofilaments, and profiles of a certain length continuous in cross-section, etc. Also used for powder granulation, dyeing, resin blending, etc.

Extrusion vs. Injection Molding Machine

The difference between an injection molding machine and an extruder.

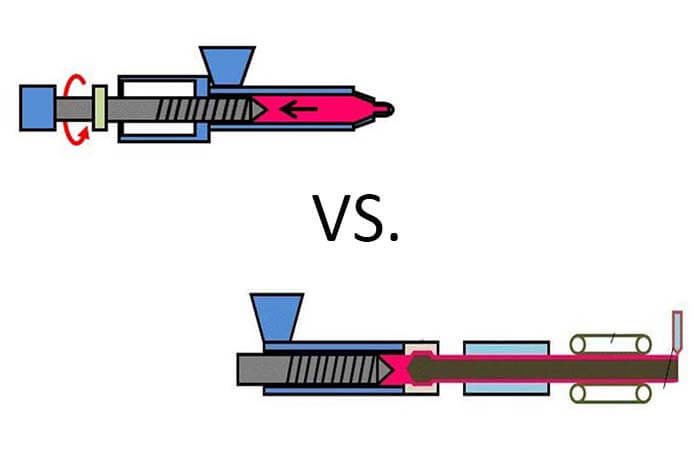

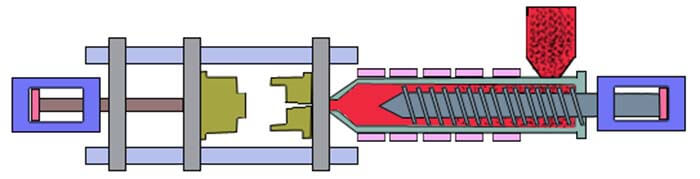

Extrusion vs. Injection Molding Machine, Different working principle

Injection molding machine working principle

An injection molding machine (injection molding machine or injection molding machine) is the main molding equipment to make thermoplastic or thermosetting materials into various shapes of plastic products using plastic molding molds, injection molding is realized by injection molding machine and molds.

Injection molding is a cyclic process, each cycle mainly includes: dosing – melt plasticization – pressure injection – mold filling and cooling – mold opening and removal. After taking out the plastic parts, the mold is closed again for the next cycle.

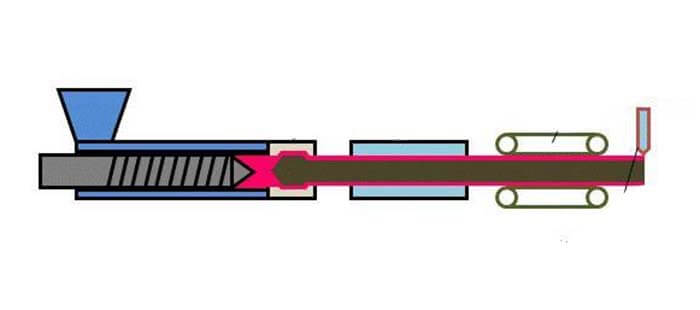

Extruder working principle

A single screw is generally divided into three sections in terms of effective length, according to the size of the screw diameter, pitch, and depth to determine the effective length of the three sections, generally divided by one-third each.

The last thread at the mouth of the material is called the beginning of the transport section: the material here requires not plasticized, but to preheat, pressed, and squeezed solid, the old extrusion theory in the past that the material here is loose body, and later by proving that the material here is actually a solid plug, that is to say, the material here is solid after extrusion like a plug, so as long as the task of conveying is its function.

Extrusion vs. Injection Molding Machine, Different features

Injection molding machine features

The injection device and the clamping device are located on the same vertical center line, and the mold is opened and closed in the up and down direction. Its floor space is only about half that of a horizontal machine, so it is about twice as productive in terms of floor space.

Extruder features

Extruders in extrusion should pay attention to the safety items are electricity, heat, mechanical rotation, and loading and unloading of bulky parts. The extruder workshop must be equipped with lifting equipment, loading and unloading the head, screw, and other bulky parts to ensure safe production.

Extrusion vs. Injection Molding Machine, Different classifications

Injection molding machine classifications

Classified by plasticizing method

(1) Plunger-type plastic injection molding machine

It is poorly mixed and plasticized, to add a diversion shuttle device. It is rarely used.

(2) Reciprocating screw-type plastic injection molding machine;

Relying on the screw for plasticizing and injection, it has good mixing and plasticizing properties and is used most often.

(3) Screw-plunger type plastic injection molding machine relies on the screw for plasticization and relies on the plunger for injection, the two processes are separated.

Extruder classifications

Plastic extruders are divided into twin-screw extruders and single-screw extruders.

Besides the Extrusion vs. Injection Molding, What Is The Difference article, you may also be interested in the below articles.

Injection Molding vs. Thermoforming, What’s the Difference?

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

What Is The Difference Between Two-Platen Mold And Three-Platen Mold?