How to Improve the Durability of Stamping Dies?

After reading this How to Improve the Durability of Stamping Dies article, you will know about the 6 best ways to improve the durability of stamping dies. There is a close relationship between the working failure of stamping dies and their durability. After working for a while, the convex die and concave die of a […]

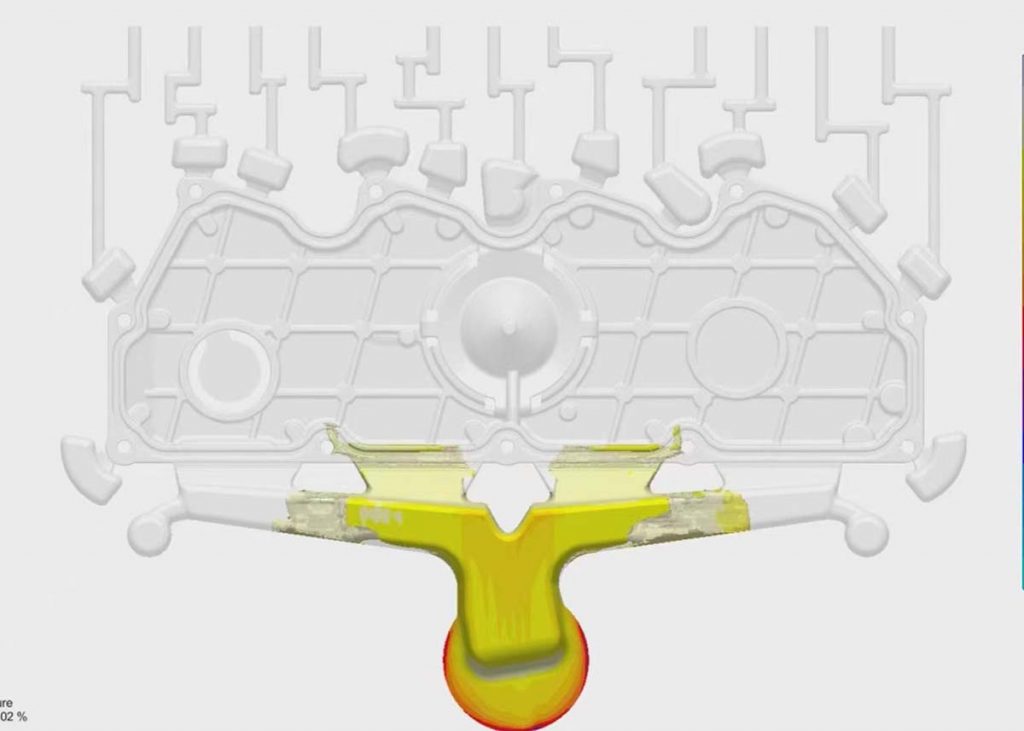

What Are The 5 Common Plastic Product Size Defects?

After reading this What Are The 5 Common Plastic Product Size Defects, you will know what the plastic product size defects are, what are the 5 common plastic product size defects and the defects analysis and troubleshooting. What is the plastic product size defect? A plastic product size defect is when the dimensions marked on […]

9 Common Injection Molding Problems and Solutions

The main purpose of this 9 Common Injection Molding Problems and Solutions article is to discuss the causes of 9 common injection molding problems and how to solve them. Injection molding problems and solutions 1. Difficult gate release During the injection molding process, the sprue sticks in the sprue bushing and does not come off […]

What is Porous Metal?

Porous metal meaning What is porous metal? Porous metal is a fine particle spherical powdered stainless steel sintered at high temperature and evenly covered with tiny air venting holes in all directions inside, also called porous steel or porous sintered metal, used in injection molds to vent air. Porous metal examples Most technical metals and […]

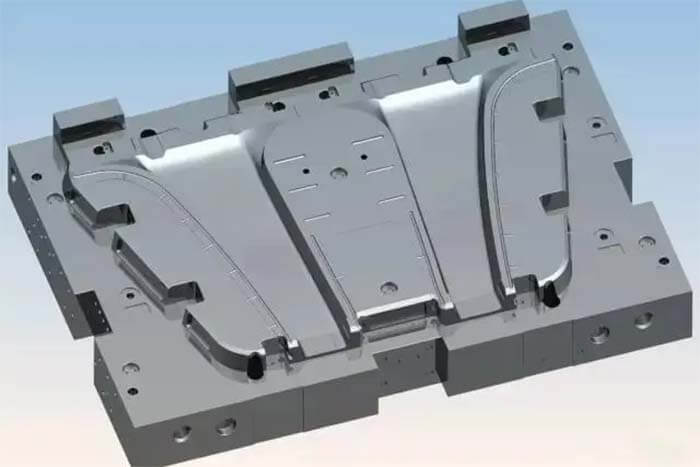

Stamping Die Design Fundamentals and Examples of Automotive Stampings

This Stamping Die Design Fundamentals and Examples of Automotive Stampings article guide us to understanding the fundamentals of die stamping. And examples of automotive stamping parts production. Definition of mold in the stamping die design fundamentals Mold is a kind of industrial product that can be made in a certain way to shape the material […]

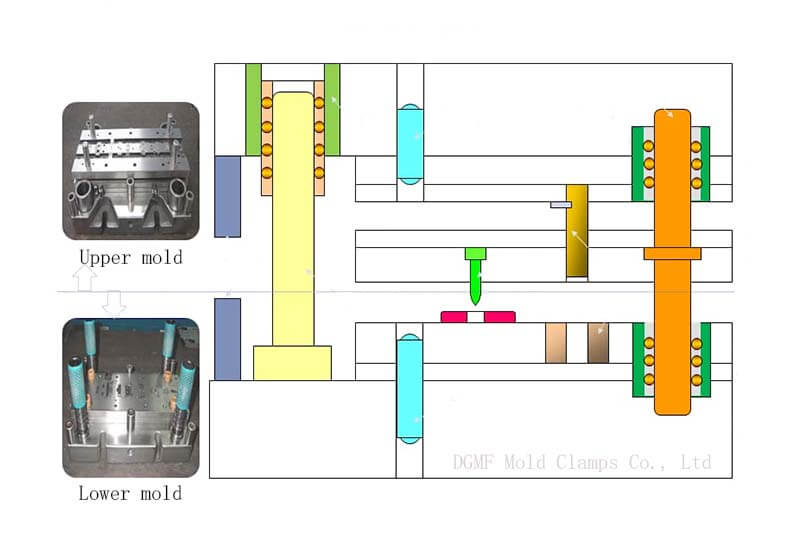

12 Types of Gates in Injection Moulding

This article discusses the 12 Types of Gates in Injection Moulding and how to select the right types of gates in injection moulding. What is an injection moulding gate? The gate of a plastic injection mould is a short section of the runner between the manifold and the cavity, which is the entrance of the […]

Plastic Injection Mold Heat Treatment Process and FAQs

This Plastic Injection Mold Heat Treatment Process and FAQs article talks about plastic injection mold materials selections, plastic injection mold heat treatment features, plastic injection mold heat treatment FAQs, mold heat treatment troubleshooting, etc. How to choose plastic injection mold materials? Plastic injection mold structure and shape are relatively complex, and the manufacturing cost is […]

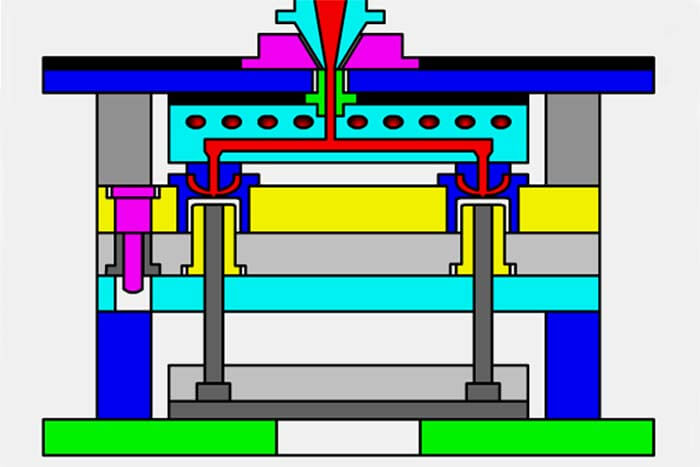

What is A Hot Runner System In Injection Molding?

What is an injection molding hot runner system? The hot runner system is a component of the injection molding system. The hot runner system is generally composed of hot nozzles, manifolds, temperature control boxes and accessories, etc. The hot nozzles generally include two types: open hot nozzles and needle valve hot nozzles. Needle valve hot […]

8 Ways to Improve Heat Treatment Deformation and Crack of Stamping Dies

There are many reasons affecting the heat treatment deformation and crack of stamping dies, mainly related to the original organization, the chemical composition of steel, the heat treatment process, the structural shape and size of the parts, and many other factors. Today, we talk about the 8 ways to improve heat treatment deformation and crack […]

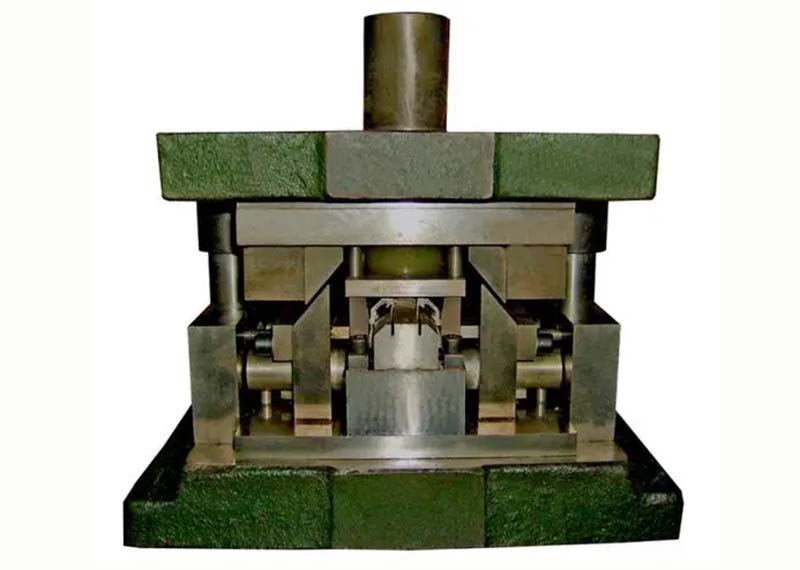

What is a Cold Stamping Mold?

What is cold stamping? Cold stamping, also known as press working, is a manufacturing operation in which thermoplastics in sheet form are cold-formed using methods similar to those used in metalworking. What is a cold stamping mold? In the cold stamping process, special process equipment to process the material (metal or non-metal) into parts (or […]