Description

What is Parting Line Component Side Lock?

Side locks are typically machined on the centerline axis, both vertically and horizontally on the outside of the mold. Side locks require the least amount of space for installation. Machining lock pockets should be done with both halves clamped together to ensure a parallel location between mold halves.

Side Locks at Mold ensure positive alignment between the top and bottom halves of the mold when the utmost accuracy is required.

Both Male and Female Side Locks are Precision Ground for positive alignment for molds with interlocking cavities and cores.

Male is manufactured from tough tool steel and hardened to 56-60 HRC.

Female is manufactured from a quality tool steel and hardened to 56-60 HRC.

Side Lock for Mold is widely used in various industrial applications.

They are fixed on the external part of the Mould where very high alignments/accuracy of mold is required.

It ensures positive alignment between Top & Bottom halves of the Mould. They are hardened & ground on a very high precession surface grinder with close tolerance.

Parting Line Component Features:

» Accurate alignment of mold halves

» Easy installation

» Industry-compatible sizes

The straight-side interlocks are designed for use on molds with floating plates when the two parting lines must be.

Side Locks include female inserts and male inserts to ensure positive alignment for multiple parting lines. Straight side Locks sets mold components, find details and Prices about Mold Interlocks Mould Locating Parts from DGMF Mold Clamps Co., Ltd.

Injection Mold Interlok Female-Male Straight Side Interlocks are available at DGMF Mold Clamps Co., Ltd.

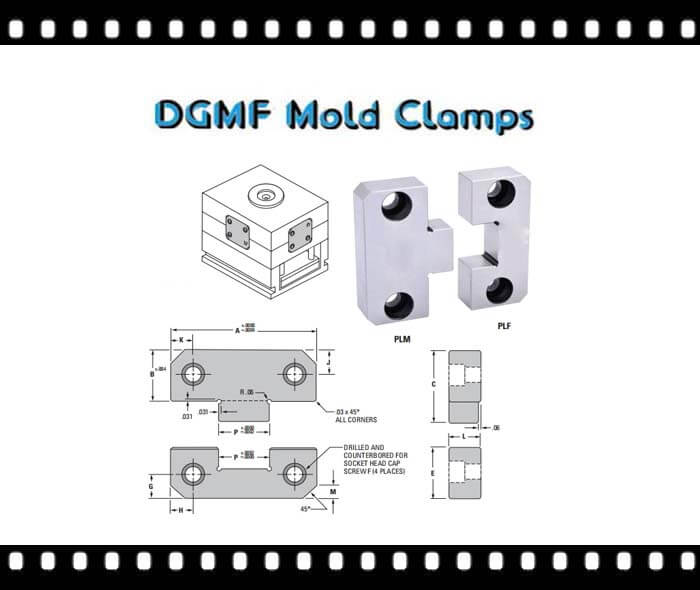

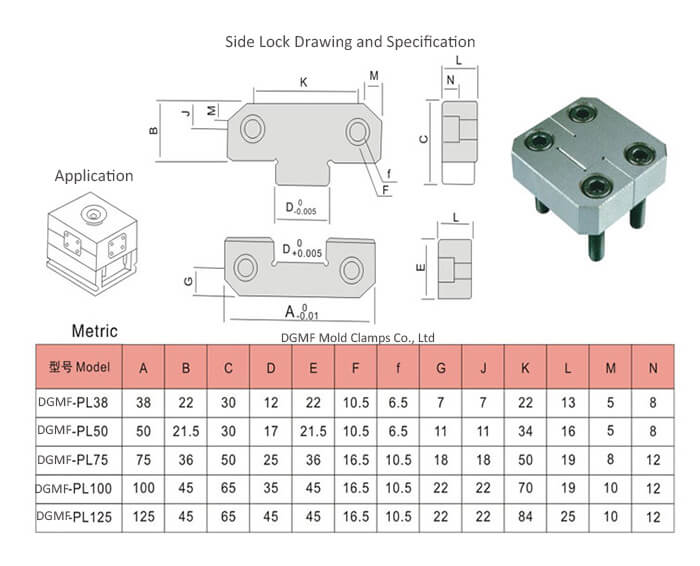

Straight Side Interlocks Product drawing and specifications:

Metric Size Chart:

| Number | Model | A | B | C | D | E | F | f | G | J | K | L | M | N |

| DGMF-052 | S38 | 38 | 22 | 30 | 12 | 22 | 10.5 | 6.5 | 7 | 7 | 22 | 13 | 5 | 8 |

| S50 | 50 | 21.5 | 30 | 17 | 21.5 | 10.5 | 6.5 | 11 | 11 | 34 | 16 | 5 | 8 | |

| S75 | 75 | 36 | 50 | 25 | 36 | 16.5 | 10.5 | 18 | 18 | 50 | 19 | 8 | 12 | |

| S100 | 100 | 45 | 65 | 35 | 45 | 16.5 | 10.5 | 22 | 22 | 70 | 19 | 10 | 12 | |

| S125 | 125 | 45 | 65 | 45 | 45 | 16.5 | 10.5 | 22 | 22 | 84 | 25 | 10 | 12 |

Straight Side Interlocks UNC Size Chart:

| Number | model | A | B | C | D | E | F | f | G | J | K | L | M | N |

| DGMF-052 | S1.0 | 1.5 | 0.87 | 1.18 | 0.5 | 0.87 | 0.433 | 0.276 | 0.281 | 0.437 | 0.938 | 0.620 | 0.19 | 0.3 |

| S2.0 | 2.0 | 0.87 | 1.18 | 0.68 | 0.87 | 0.433 | 0.276 | 0.375 | 0.437 | 1.25 | 0.62 | 0.19 | 0.3 | |

| S3.0 | 3.0 | 1.36 | 1.91 | 1.00 | 1.37 | 0.59 | 0.413 | 0.688 | 0.688 | 2.25 | 0.745 | 0.38 | 0.45 | |

| S4.0 | 4.0 | 1.87 | 2.64 | 1.375 | 1.87 | 0.59 | 0.413 | 0.875 | 0.875 | 2.75 | 0.745 | 0.50 | 0.45 | |

| S5.0 | 5.0 | 1.87 | 2.64 | 1.75 | 1.87 | 0.788 | 0.555 | 0.875 | 0.875 | 3.50 | 1.12 | 0.50 | 0.60 |

These UNC-size Straight Side Interlocks are equal to DME PLM/PLF models.

DGMF-Mold-Clamps-052-S1 equal to DME PLM-0001/PLF-0001 model

DGMF-Mold-Clamps-052-S2 equal to DME PLM-0002/PLF-0002 model

DGMF-Mold-Clamps-052-S3 equal to DME PLM-0003/PLF-0003 model

DGMF-Mold-Clamps-052-S4 equal to DME PLM-0004/PLF-0004 model

DGMF-Mold-Clamps-052-S5 equal to DME PLM-0005/PLF-0005 model

TO ORDER SPECIFY: Number-Model

Side Locks ensure positive alignment between the top and bottom halves of the mold when the utmost accuracy is required. Side locks consist of two pieces: a male made of black oxide-coated hardened to 60-62 Rc and a female made of TIN-coated hardened to 50-52 Rc. It extensively serves in the fields of metal stamping die, plastic die, die casting die, and automobile, machinery, and electronics manufacturing.

DGMF Mold Clamps Co., Ltd supplies the ejector pins, straight ejector pins, ejector sleeve pins, ejector blades, shoulder ejector pins, guide pins, core pins, angle pins, dowel pins, guide bushing, A-type sprue bushing, B-type sprue bushing, C-type sprue bushing, small gate sprue bushing, big gate sprue bushing, support pillars, slide retainer, taper block set, round tapered interlocks, side lock, etc.

Contact the DGMF team for the injection mold components specification, inventory, and pricing.

DGMF Mold Clamps Co., Ltd is the mold clamps Manufacturer in China, also provides injection mold components, die press components, machine tools, and fasteners for your best choice. Contact us for more details.

Reviews

There are no reviews yet.