After reading this What Are The 5 Common Plastic Product Size Defects, you will know what the plastic product size defects are, what are the 5 common plastic product size defects and the defects analysis and troubleshooting.

What is the plastic product size defect?

A plastic product size defect is when the dimensions marked on a product do not match the actual measurements, and the local structure does not meet the customer’s labeling requirements.

Plastic product size defects belong to the key dimensions marked by the customer, which are serious defects and must be improved until the dimensions are free from problems.

If it belongs to non-important dimensions, you can negotiate with the customer to relax the tolerance appropriately and modify the drawings to meet the requirements.

From the perspective of plastics, the causes of plastic product size defects are mainly the following three points:

- The change of pressure distribution in the cavity will cause dimensional changes;

- For crystalline plastics, changes in crystallinity due to changes in cooling rate can cause dimensional changes;

- Changes in product post-processing, ambient temperature, and humidity can also cause dimensional changes.

The plastic product size defects need to be reversed by adjusting the amount of injection pressure and checking whether there is any change in the plastic product size defect.

If the size improvement meets the requirements of customer drawings, the problem is solved.

If the change does not meet the requirements of the customer’s drawings, we should analyze the stability of the injection molding machine to confirm. The stability of the injection molding machine should be analyzed and confirmed.

The following is an analysis and discussion on the change of pressure distribution in the cavity, causing dimensional changes. Dimensional changes in different manifestations, the formation of plastic product size defects will be different.

Plastic Product Size Defect 1: The overall product size is too small

Cause analysis:

The plastic pressure inside the cavity is too low.

Solution idea:

Increase shrinkage pressure to achieve the required cavity pressure of qualified products.

Plastic Product Size Defect 2: The overall product size is too large

Cause analysis:

Plastic pressure in the cavity is too high.

Solution:

Reduce the shrinkage pressure to achieve the required cavity pressure of qualified products.

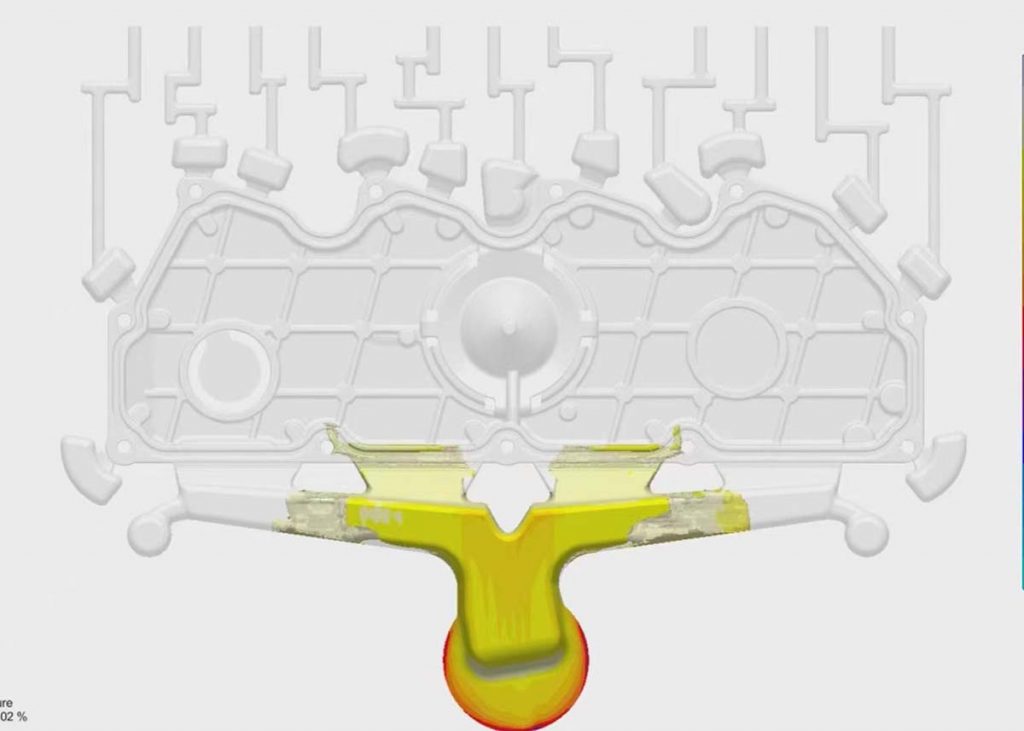

Plastic Product Size Defect 3: The size of the product near the gate is too small, the size of other locations is normal

Cause analysis:

The pressure near the gate is too low. Mainly because the gate is not frozen, plastic reflux.

Solution idea:

Increase the holding time, or according to the other reasons for the gate did not freeze (such as plastic or mould temperature due to the gate did not freeze), targeted adjustments to the process.

Plastic Product Size Defect 4: The size of products near the gate is too large, the size of other locations is normal

The pressure near the gate is too high.

Solution idea:

If the use of a three-stage molding process, a change in the rate of filling shrinkage can be solved. Check the effective viscosity (injection pressure integral of filling stage), measure the plastic temperature, and adjust.

If the two-stage molding process, changes the filling rate, make-up shrinkage rate and pressure can be solved.

Plastic Product Size Defect 5: Product size fluctuations back and forth, unstable

Cause analysis:

This is caused by fluctuations in cavity pressure. Observe the fluctuation of the cavity pressure curve. If the cavity pressure distribution of each mold is changing, check whether there is a trend over time.

If there is a trend of change, it indicates a change in temperature or a change in material batch;

On the contrary, if it is different from one mold to another, it means that there is a change in the process of making up and shrinking which leads to a change in the freezing of the gates, some of which freeze and some of which don’t;

It may also be due to the leakage of the non-return ring and so on, which leads to a change in the pressure.

Solution idea:

Do the sprue freezing test and dynamic non-return ring leakage test to determine the cause and solve the problem in a targeted manner.

Besides the What Are The 5 Common Plastic Product Size Defects article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

What Is The Difference Between Two-Platen Mold And Three-Platen Mold?