After reading this How to Improve the Durability of Stamping Dies article, you will know about the 6 best ways to improve the durability of stamping dies.

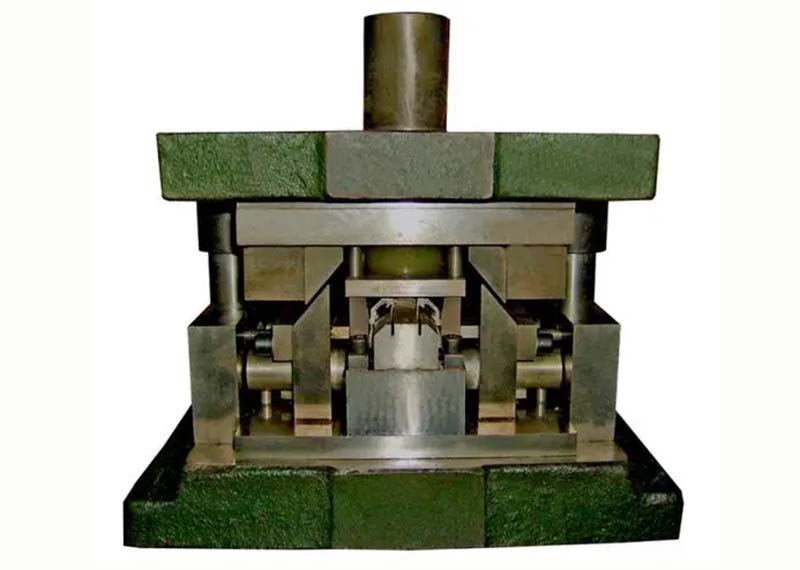

There is a close relationship between the working failure of stamping dies and their durability. After working for a while, the convex die and concave die of a stamping die lose their working dimensions due to frequent wear and tear, and can no longer meet the technical conditions of stamped parts, therefore, the durability is determined by the total number of parts stamped by the die.

A pair of stamping molds from design, machining, assembly, adjustment to installation and use, the process is many, the cycle is long, and the processing cost is high. Therefore, for the stamping die, in addition to the requirements of high production efficiency, the punched parts fully meet the quality requirements and technical conditions, the durability of the stamping die itself is also very important.

To improve the durability of stamping dies method 1. Improve the design of the stamping die mold

The rationality of the design of the stamping die is the basis for improving the durability of the die. Therefore, when designing the die, effective measures should be taken to improve the durability of the die by the unfavorable conditions in the forming of products.

For example, when designing a small hole punching die, its life is often shown in the punching of small holes on the convex die, for this punching die, when designing, it should make the length of the tiny convex die shorten as much as possible, to increase the strength.

At the same time, the guiding sleeve method should be used to strengthen the small convex die to protect it.

In addition, the design of the punching die, should fully consider the form of the die frame, convex and concave die fixing method and guiding form, the determination of the pressure center and the rigidity of the upper and lower templates, and other factors. Especially for the blanking die, the selected clearance value has a great influence on the durability.

When designing, the clearance of the punching die should be selected reasonably, and its clearance value should not be too small, otherwise, it will affect the service life and durability of the punching die.

Practice has proved that, without affecting the quality of the stamped parts, the appropriate enlargement of the gap can greatly improve the durability of the die, and sometimes even increase several times and dozens of times.

To improve the durability of stamping dies method 2. Correct selection of stamping die materials

Different stamping die materials have different strengths, toughness, and wear resistance. Under certain conditions, using advanced materials can increase its durability several times.

For example, with T10A steel made of electricity meter pole punching piece die, then with Cr12 and Cr12MoV made of the same kind of die of a sharpening life is much lower;

With G35 titanium carbide steel carbide, the average life of each sharpening than the Cr12 steel die improved 5-10 times;

If the use of tungsten-cobalt carbide as a similar convex, concave die material, and Cr12 steel improves 20-30 times.

Therefore, to improve the durability of the die, it is necessary to choose a good die material.

To improve the durability of stamping dies method 3. Reasonable forging and heat treatment of stamping die parts

At the same time of choosing high-quality die materials, forging and heat treatment reasonably for the same material and different nature of material requirements is one of the main ways to improve the durability of the die.

For example, when quenching, if overheating occurs when heating, it will not only make the workpiece too brittle but also easily cause deformation and cracking when cooling, which will reduce its durability, therefore, it is necessary to reasonably master the heat treatment process when manufacturing punching dies.

To improve the durability of stamping dies method 4. Reasonable arrangement of the manufacturing process of punching mold and ensuring the machining precision

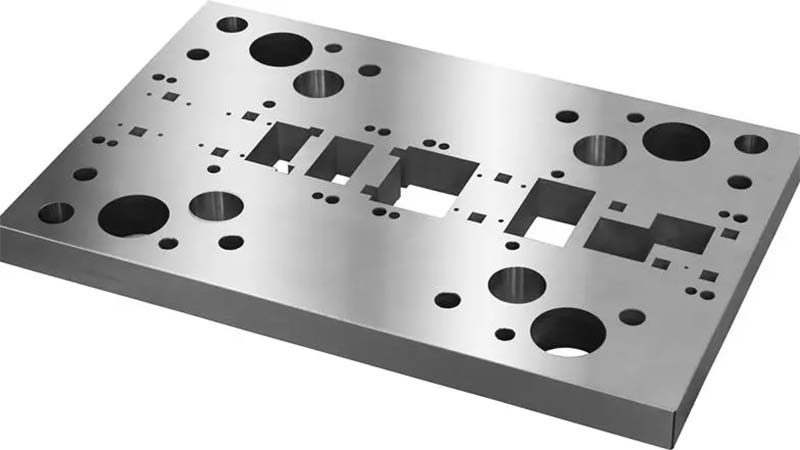

The processing accuracy of the die has a great influence on the durability of the die. For example, in the blanking mold, due to the uneven assembly clearance, under the action of shear force, it will often make the concave die gnaw badly and affect the life of the die. At the same time, the surface finish of the die is too low, which will also reduce the durability of the die.

Therefore, it is necessary to pay full attention to the size of the hole distance, the perpendicularity of the convex die to the support surface of the fixed plate during assembly, the uniformity of the die spacing, and the guiding accuracy level of the guide pillar and guide bushing during processing.

The higher the manufacturing and assembly accuracy, and the higher the surface roughness of the working part, the higher the durability of the stamping die.

To improve the durability of stamping dies method 5. Correct selection of presses

To improve the durability of the stamping die, the press with higher precision and rigidity should be selected, and the punching tonnage should be more than 30% of the punching force.

To improve the durability of stamping dies method 6. Reasonable use and maintenance of punching die

To improve the durability of the stamping die, the operator must reasonably use and maintain the punching die, and the punching die should be maintained frequently to prevent the punching die from working with disease.

Warm reminder: the durability of punching die is of great significance in production. The higher the durability of the stamping die, the longer the service life of the die and the lower the cost of the punched parts.

Besides the How to Improve the Durability of Stamping Dies article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

What Is The Difference Between Two-Platen Mold And Three-Platen Mold?