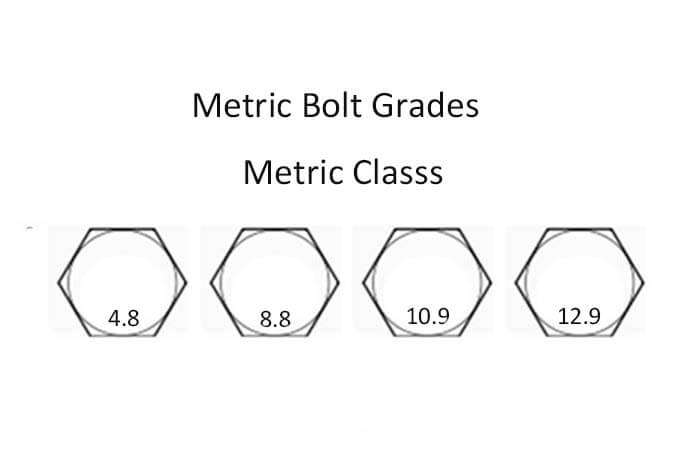

What Are Metric Bolt Grades?

What are metric bolt grades indicated? The metric bolt grades are designated by a symbol of 2 numbers, separated by a decimal. The common metric bolt grades/classes are 4.8, 8.8, 10.9 and 12.9. The metric bolt grades have specific bolt strength grades. No matter the system used to grade the bolts, the higher the bolt […]

What Is Deep Drawing?

What is deep drawing process? Deep drawing is a sheet metal drawing process method that uses a die to form sheet metal into an open hollow part or changed it into a curved body. Deep drawing operation in sheet metal is widely used as one of the main stamping processes. The mean of deep drawing, […]

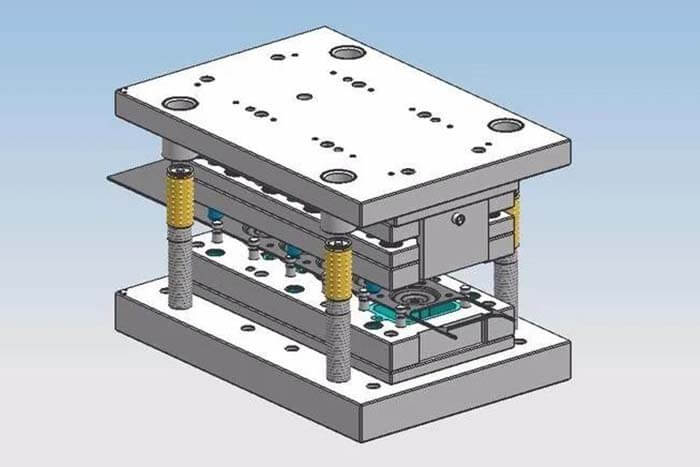

Plastic Injection Molding vs. 3D Printing, What’s the Difference?

After the read about Plastic injection molding vs. 3D printing, What’s the Difference; you will know: Plastic injection molding vs. 3D printing, What is the difference between injection molding and 3D printing? Plastic injection molding vs. 3D printing process Plastic injection molding vs. 3D printing strength Plastic injection molding vs. 3D printing materials Plastic injection […]

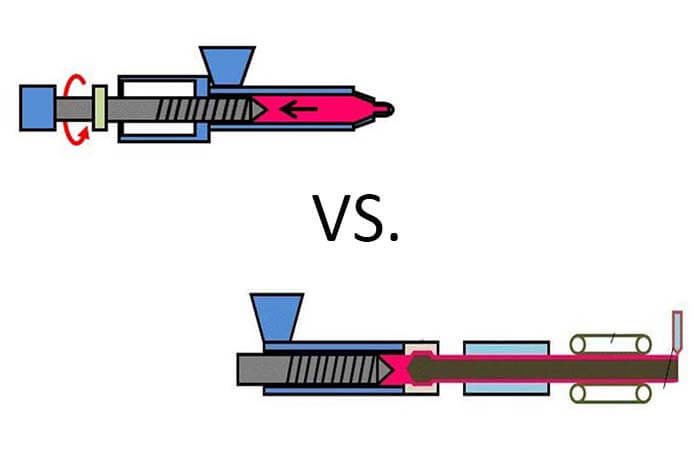

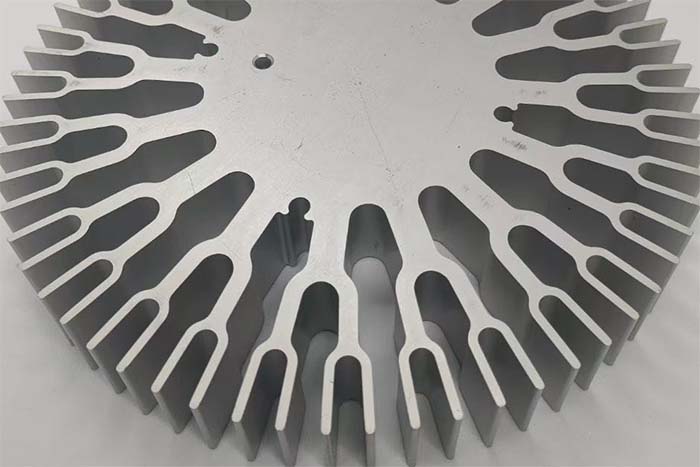

Extrusion vs. Injection Molding, What Is The Difference?

After the read of Extrusion vs. Injection Molding, What Is The Difference, you will know: Extrusion vs. Injection Molding Principle Extrusion vs. Injection Molding Process Extrusion vs. Injection Molding Time Extrusion vs. Injection Molding Methods Extrusion vs. Injection Molding Features Extrusion vs. Injection Molding Materials Extrusion vs. Injection Molding Advantages and Disadvantages Extrusion vs. Injection […]

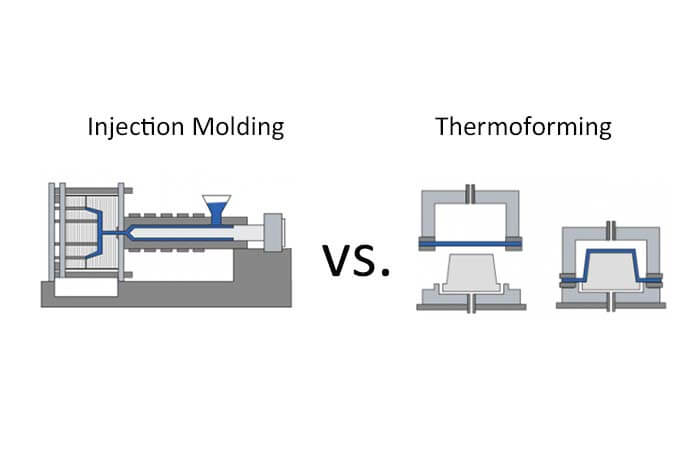

Injection Molding vs. Thermoforming, What’s the Difference?

After the read of Injection Molding vs. Thermoforming, you will know: Injection molding vs. thermoforming principle Injection molding vs. thermoforming advantages Injection molding vs. thermoforming types Injection molding vs. thermoforming materials Injection molding vs. thermoforming cost Injection molding vs. thermoforming products Injection molding vs. thermoforming, What is the difference between thermoforming and injection molding? Plastics […]

30 Die Stamping Problems And Troubleshooting

This article summarizes 30 Die stamping problems and troubleshooting for your reference. Die Stamping Problems And Troubleshooting 1. The convex die wears too fast (1) The clearance of the die is small, generally, the total clearance of die stamping mold is 20%, 25% of the material plate thickness. (2) Bad alignment of the convex and […]

How Do Choose The Injection Speed In Injection Molding?

Do you know how to choose the injection speed in injection molding? Control of the injection molding process directly impacts the quality of the final part and the economy of the process. The control parameters of the injection molding process must be studied in depth in order to facilitate maximum efficiency and best part quality. […]

What Are The 24 Different Types Of Metal?

This article introduces 24 different types of metal materials commonly used in machinery and mold processing and their characteristics! Different types of metal materials 1. 45# steel What is 45# steel? 45# is a high-quality carbon structural steel, corresponding to the Japanese standard S45C, American standard: 1045, and German standard C45. Its characteristics are higher […]

185 Injection Moulding Die Design Experiences

185 injection moulding die design experiences are precious information! Worth collecting. The 1 to 10 injection moulding die design experiences The height of the slider guide should be at least 1/3 of the slider height to ensure the stability of the slider and smooth sliding. Sliding friction positions attention to open lubrication groove, in order […]

85 FAQs of TPM Management

There are 85 FAQs of knowledge about TPM management, here we go! 1. What is TPM management? A: In terms of management, TPM (Total Productive Maintenance) is an activity to improve the overall efficiency of a company’s equipment. TPM (Total Productive Maintenance) is an activity of equipment maintenance and repair based on the prevention and […]