Mold clamp tools defination

What is mold clamp? The mold clamp (also called mould clamp) is a kind of auxiliary clamping unit often used in injection mold processing, its main function is to keep the machined parts not shaking not moving in the processing.

What is mold clamp used for?

Mold clamp for the mechanical workpiece fixation of various solid bodies on a work plate or holder. Mostly the mold clamp is used for plastic injection molding machinary and CNC machinery.

Why mold clamp is so important?

The quality of the mold clamp directly affects the quality of the mold. The mold clamp plays a vital role in the mold manufacturing process. We need to ensure the accuracy and good finish of the mold workpiece. The mold clamp has high strength, small size, flexible and easy to operate.

What is mold clamp made of?

Mold clamp is made of long lasting through-hardened steel.

Mold clamp is forged from 45# medium carbon steel and quenched at high temperature to reach 35HRC to 40HRC as required by JB, and finally the surface is blackened or blued to achieve the purpose of no rust.

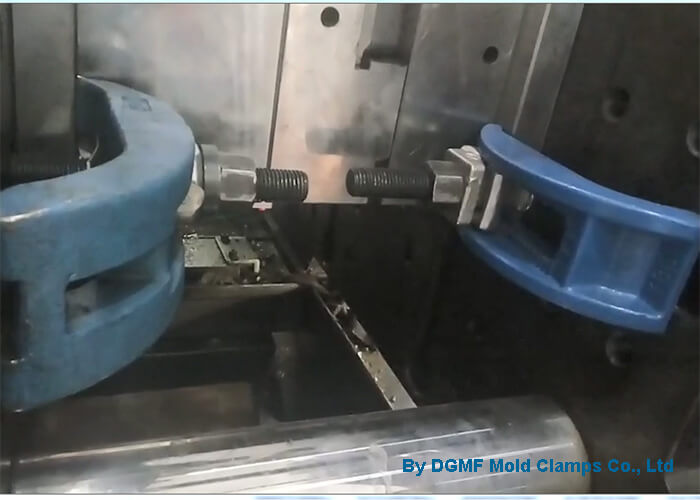

These mold clamps are used for injection molding industry. These are useful for clamping of molds on plastic injection molding machines.

What is mold clamp feature?

High speed to change and fix your mold;

Varied mold clamp sizes with M10, M12, M14, M16, M18, M20, M24, M30 mold clamp specs;

The mold clamp material is harded and more tough. Not easy to bend and eliminates the fracture;

Made of long-lasting through-hardened steel;

Appreciated for quality, corrosion resistance, and high durability;

Reasonal mold clamp price;

Mold clamp bolts are adjust to different mold clamp thicknesses.

Easy to install and equip with self-adjustable mode.

What is mold clamping unit?

The mold clamping units are used to keep the injection mold shut against the forces developed when injection pressure pushes plastic into the closed mold.

Therefore, the amount of mold clamping force must be at least equal to the amount of injection molding force. The machine sizes are determined by the clamping tonnage forces.

What is mold clamp force?

The mold clamp force refers to the force applied to an injection mold by the clamping unit mold clamp of an injection molding machine. In order to keep the injection mold closed, this clamping force must oppose the separating force, caused by the injection of molten plastic into the injection mold.

The mold clamp force rating is stated in tons, e.g. a 400 ton machine is capable of producing a maximum clamping force equivalent to a total of 400 tons.

The mold clamp force calculation tonnage can be used to select a capable machine that will prevent part defects, such as excessive flash.

What injection mold clamp tonnage calculation is required?

The required mold clamp force can be calculated from the cavity pressure inside the mold and the shot projected area, on which this pressure is acting.

There are variables that affect the mold clamp force calculation, like the material type (low-flow or high-flow plastic), and the depth of the part.

What is clamping pressure?

Clamping pressure is a measurement of the mold clamp force needed to hold the injection mold closed during injection. If this clamping pressure is not set high enough, the injection mold will be forced open prematurely by injection molding pressure and will create flash on the related molded part.

What is mold clamp type?

There are many types of mold clamp in the market, such as:

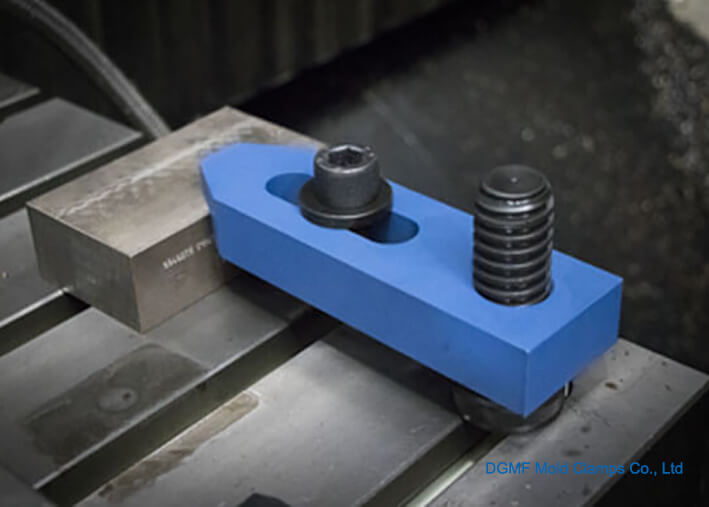

Forged Mould Clamps with blue color

Forged Mold Clamp For Injection Molding with black color

Closed Toe Mold Clamps with step tap

What is mold clamp assembly?

Injection Mold Clamp Sets

Step Blocks And Strap Clamps

What is mold clamp parts?

What is mold clamp specification?

Normally, we have the mold clamp size include mold clamp M10, mold clamp M12, mold clamp M16, mold clamp M20, mold clamp M24, mold clamp M30, etc.

What is mold clamp unit HS code?

The mold clamp unit HS Code is 84779000.

How to install injection mold clamps?

Quick-change injection mold clamps for injection molding machine installation method

Closed toe mold clamp with tap end injection mold clamp installation way

Step blocks and strap clamps for CNC machine installation method

Easy clamp for fixing mold installation method

What is mold clamp price?

Different mold clamp specification has different mold clamp price, contact us for the mold clamp specification and mold clamp price now.

Who is the mould clamp manufacturer?

DGMF Mold Clamps Co., Ltd is the mold clamp supplier and mould clamp manufacturer in China. We provide all kinds of mold clamps for your best choice, do not hesitate to contact us for the mould clamps.

Besides the What is Mold Clamp article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept

18 FAQ Of Injection Molding Machine Mold Clamping