Description

What is Cast Iron Angle Plate?

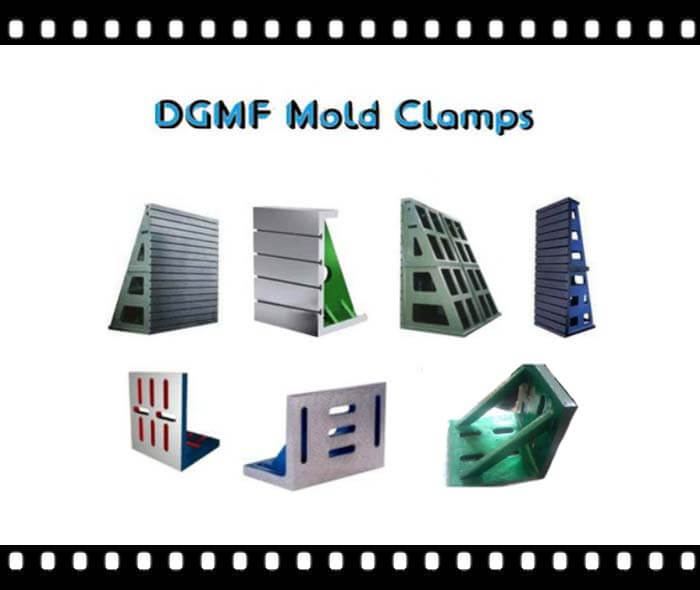

Cast Iron Angle Plate is an angle plate, casting angle plate, inspection angle plate, cast iron right angle plate, and slotted cast iron angle plate.

The cast iron right angle plate is a kind of machine tool used to inspect the 90° angle of the workpiece tools and to inspect the mutual perpendicularity of the related surfaces of the parts when the equipment is repaired.

Features of the Cast Iron Angle Plate?

The cast iron right angle plate is accurate and durable

The cast iron right angle plate reference measuring tool used for workpiece inspection or scribing is accurate in measurement, and the size can be customized to meet your different needs

Smooth surface and beautiful appearance

The surface of the cast iron right angle plate product is smooth, the strength is good, it is not easy to deform, the operation is smooth, and the measurement is convenient

High strength

Cast iron surface hardness reaches HB170-200

High precision

High precision, high stability, and strong precision, there are three levels: 1st, 2nd, 3rd

High hardness

The heat treatment of the cast iron right angle plate is guaranteed, and the flatness will not be deformed

Cast Iron Right Angle Plate For Milling Machine is supplied by DGMF Mold Clamps Co., Ltd. We provide black and green colors for the precision right-angle plates. Contact us for the slotted angle plate price, machinist angle plate inventory, etc.

Classification of Cast Iron Angle Plate

Cast Iron Angle Plates are divided into cast iron angle plates, right-angle plates, T-slot angle plates, ordinary angle plates, spliced angle plates, granite angle plates, marble angle plates, granite angle plates, right-angle bent plates, and right-angle bending squares.

Cast Iron Angle Plate is also often used for fitter marking, and is also used for inspection, installation, and vertical inspection of machine tools, and can check the verticality of workpieces on a flat plate.

Accuracy: Level 0, Level 1, Level 2, Level 3.

Accuracy chart

| Specification(mm) | Measure the perpendicular to the base surface | Flatness or straightness of measuring surface | Reference flatness or straightness | ||||||

| Accuracy class (um) | |||||||||

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |

| 200×200 | 8 | 16 | 30 | 4 | 8 | 16 | 6 | 12 | 24 |

| 300×200 | 10 | 20 | 40 | 5 | 10 | 20 | 8 | 16 | 30 |

| 300×300 | 10 | 20 | 40 | 5 | 10 | 20 | 8 | 16 | 30 |

| 400×300 | 12 | 24 | 45 | 6 | 12 | 24 | 10 | 20 | 40 |

| 400×400 | 12 | 24 | 45 | 6 | 12 | 24 | 10 | 20 | 40 |

| 500×400 | 14 | 28 | 50 | 7 | 14 | 28 | 12 | 24 | 48 |

| 500×500 | 14 | 28 | 50 | 7 | 14 | 28 | 12 | 24 | 48 |

| 800×600 | 18 | 35 | 60 | 9 | 18 | 35 | 14 | 28 | 55 |

Specifications of Cast Iron Angle Plate

| Specification/SKU | Size | L(MM) | W(MM) | H(MM) | T(MM) | S/W(MM) | S/D(MM) | Weight(KG) |

| DGMF-Mold-Clamps-CIAP-6 | 6 Inch | 155 | 117 | 130 | 22 | 13 | 20 | 5 |

| DGMF-Mold-Clamps-CIAP-8 | 8 Inch | 210 | 125 | 145 | 22 | 15 | 20 | 7 |

| DGMF-Mold-Clamps-CIAP-10 | 10 Inch | 260 | 130 | 200 | 22 | 15 | 20 | 11 |

| DGMF-Mold-Clamps-CIAP-12 | 12 Inch | 310 | 170 | 230 | 22 | 20 | 30 | 17 |

| DGMF-Mold-Clamps-CIAP-14 | 14 Inch | 350 | 208 | 275 | 25 | 20 | 39 | 28 |

| DGMF-Mold-Clamps-CIAP-16 | 16 Inch | 400 | 250 | 310 | 25 | 20 | 40 | 42 |

| DGMF-Mold-Clamps-CIAP-18 | 18 Inch | 450 | 300 | 380 | 30 | 22 | 45 | 62 |

| DGMF-Mold-Clamps-CIAP-20 | 20 Inch | 510 | 360 | 430 | 30 | 22 | 45 | 80 |

Cast Iron Angle Plate detailed parameter description

Effects of the Cast Iron Angle Plate

1. The angle seat can be used as a reference right angle seat

2. Suitable for all kinds of molds and fixtures, such as drilling and milling processing

3. The fixed surface, after grinding, the angle is accurate

Mechanical Cast Iron Angle Plate production standards and uses

Manufactured according to GB6092-85 standard, material HT200-250. Used for component inspection and clamping in machining.

It is used to check the 90° angle of the workpiece and to check the mutual perpendicularity of the related surfaces of the parts when the equipment is repaired.

It is also often used for fitter marking. It can also be used for inspection, installation, a vertical inspection of machine tools, and the verticality of workpieces on cast iron plates.

Note:

Do not use and store cast iron bent plates in humid, corrosive, high and low-temperature environments. When in use, install and debug the cast iron bent plate, then wipe the working surface of the cast iron bent plate clean, and use the cast iron bent plate when it is confirmed that there is no problem.

What is an angle plate?

An angle plate is a work-holding device used as a fixture in metalworking.

Angle plates are used to hold workpieces square to the table during marking-out operations.

Adjustable angle plates are also available for workpieces that need to be inclined, usually towards a milling cutter. Angle plates are made from high-quality material (generally spheroidal cast iron) that has been stabilized to prevent further movement or distortion.

Slotted holes or “T” bolt slots are machined into the surfaces to enable the secure attachment or clamping of workpieces to the plate, and the plate to the worktable.

A very useful tool when it comes to work holding or alignment is the angle plate. An angle plate is simply a device with two flat surfaces at right angles to each other. The inside surfaces of an angle plate can either be the rough surface from when it is cast or they can be machined to be flat and parallel to the outer surfaces.

Angle plates are usually made from cast iron or steel. The end surfaces are always machined to be flat and square. Large angle plates often have a web at the end unless they are machined on the inside in which case they are never webbed.

Angles plate might have two flat surfaces with no holes or slots in them at all. In this case, it is up to the user to make whatever holes, etc.

Otherwise, an angle plate might have various patterns of holes and slots and T-slots that can be used for holding the angle plate to something or for holding work-holding devices or workpieces onto the angle plate.

The Machine Tools Machine Anti-Vibration Mounts Machine Tool Sizing Block Adjustable Shock Pad, Shock Absorption Pad Iron Machine Anti-Vibration Mounts, Anti-Vibration Pad Wedge Mounts, Heavy-duty Machine Leveling Wedges, Precision Machine Wedge Leveling Blocks, and A-type Anti-Vibration Pad Wedge Mounts are also supplied by DGMF Mold Clamps Co., Ltd.

The Precision Cast Iron Angle Plates for Milling Machine is available at DGMF Mold Clamps Co., Ltd, we provide machine tool accessories, clamping toolings, mold components, etc.

Besides the Precision Cast Iron Angle Plate style, DGMF Mold Clamps Co., Ltd also provides the 45-degree adjustable angle plate for the milling machine, 90-degree swivel-type angle plate for the milling machine, and slotted angle plate for the milling machine style of your choice.

Contact us for more details on the T slot angle plate milling table such as T slot angle plate milling table pricing, and T slot angle plate milling table inventory.

Or other angle plates for milling machine styles.

Contact us for more information you need, thank you.

Reviews

There are no reviews yet.