What Is The Difference Between Blow Molding And Injection Molding?

What Is The Difference Between Blow Molding And Injection Molding? First, the process is different Blow molding Blow molding uses gas pressure to inflate the hot parison closed in the mold into a hollow product, or the tube parison is inflated into a tube film without a mold. Injection molding Injection molding is to melt […]

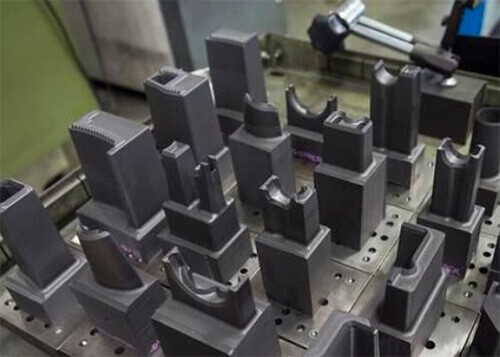

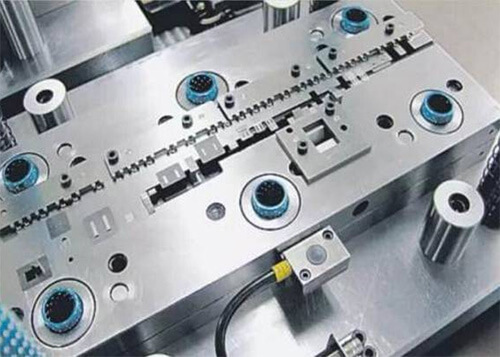

Nine Steps Of Stamping Die Design

Stamping die is a method of pressure processing of parts, so the design of stamping die is very helpful to the manufacturing process of parts. How to design the stamping die reasonably, then the manufactured parts are much better, which can be concluded through analysis the following 9 core steps of stamping die design. Nine […]

Stamping Die Data Summary

Stamping Die Data Summary Information is seen from the waste situation The waste is essentially the reverse image of the formed hole. That is the same part of the opposite position. By checking the waste, you can judge whether the gap between the upper and lower molds is correct. If the gap is too large, […]

17 Common Problems And Solutions For Stamping Dies

This article summarizes 17 common problems of stamping dies and lists some solutions for your reference. 17 Common Problems And Solutions For Stamping Dies Scrap jump hole 1) The length of the punch is not enough, cut into the die according to the edge of the punch, add a thickness of 1mm to replace the […]

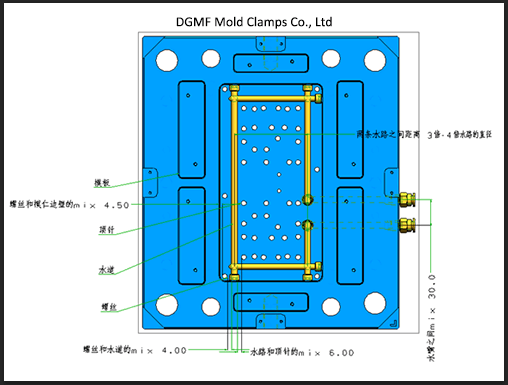

What Affects The Cooling Efficiency Of The Mold?

With the rapid development of social economy, our lives are almost inseparable from the convenience brought by plastic injection molded parts. The quality standards for plastic products are becoming stricter and more refined. The control of mold temperature is an important consideration in the injection molding process. Not only will it be reflected in the […]

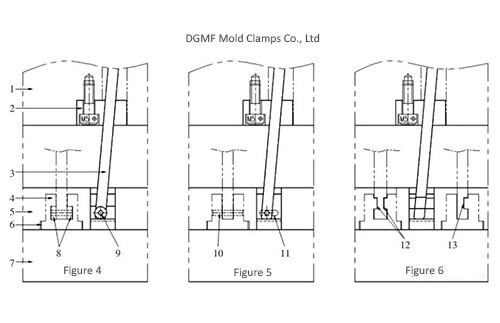

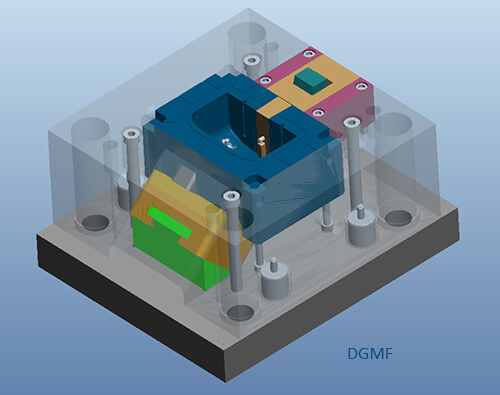

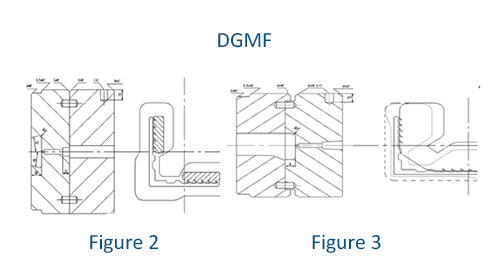

Various Inclined Top Ejection Structures Of Injection Mold

Various Inclined Top Ejection Structures Of Injection Mold This article analyzes various slanting top ejection mechanisms of injection molds, explains their respective advantages and disadvantages, and has a certain guiding role for technical personnel engaged in injection mold design and related work. 1. Selection of the parting line position of the connecting part of the […]

Specification For Installation And Adjustment Of Plastic Injection Molds

Specification For Installation And Adjustment Of Plastic Injection Molds Plastic Injection Mold Pre-inspection Before the plastic injection mold is processed and installed on the injection molding machine, it should be inspected in order to find quality problems in time, and the injection mold can be repaired to avoid removal after the machine is installed. When […]

Six Elements Of An Aluminum Extrusion Die Design

In recent years, with China’s large-scale infrastructure investment and the rapid progress of industrialization, the output and consumption of aluminum profiles in the whole industry have grown rapidly, and China has also become the world’s largest aluminum profile production base and consumer market. After nearly 10 years of rapid growth, my country’s aluminum profile industry […]

What Should I Pay Attention to In The Production Of Plastic Molds?

The first thing to look at is the complexity of the structure of the mold. Generally speaking, it takes about a month to open a plastic mold. The time required for a mold with a complex process is more durable. Usually, a plastic mold is opened, it is necessary to do a detailed review, and […]

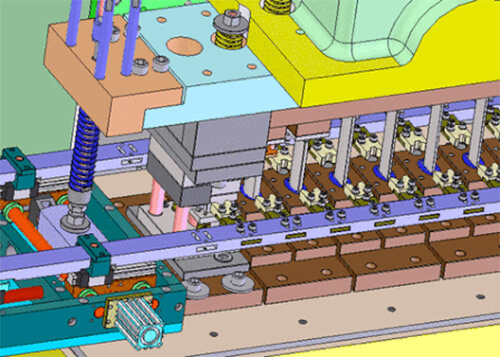

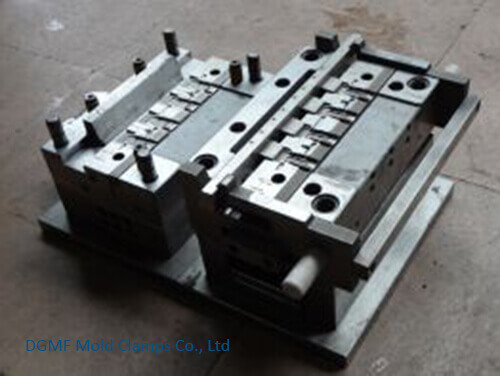

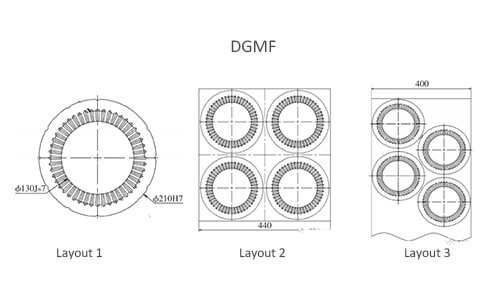

One-die Double-punch Compound Die

One-die Double-punch Compound Die Technology Sharing The structure exploration and manufacturing process analysis of the one-die double-punch compound die. Through the systematic optimization of the structure and the analysis of the manufacturing process, the die structure was innovated and the technical difficulties of the one-die double-punch compound die were solved. The punching quality of the […]