After the read, you can learn the 7 plastic injection mold polishing techniques.

What is plastic injection mold polishing?

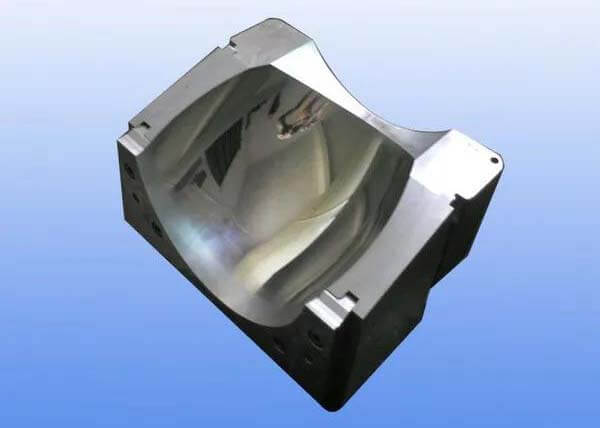

Plastic injection mold polishing is a technique that helps to obtain smooth mold surfaces. It does this by removing the convex parts of the mold through plastic deformation and cutting. Generally, mold polishing techniques use wool wheels, whetstone strips, and sandpaper for manual polishing.

Nowadays, in the process of developing machined products in the direction of diversification and precision, it has become an important task to improve the quality of molds.

In the process of mold manufacturing, the surface grinding and polishing process of parts after shape processing has become an important process to improve the quality of molds.

The reasonable use of polishing methods is of great help to improve the quality and service life of the mold. So, what are the common plastic injection mold polishing methods?

Mechanical polishing-plastic injection mold polishing

Mold polishing, by cutting or making the surface plastic deformation, and removing the surface of the workpiece convex part of the polishing method to get a smooth surface.

The most commonly used is whets stone, wool wheel, sandpaper, etc., mainly by hand, the surface quality requirements of high can use the method of ultra-precision grinding.

Ultra-precision grinding and polishing, the use of specially designed abrasives, in the grinding and polishing fluid containing abrasives, tight pressure on the surface of the workpiece being processed, for high-speed rotary motion.

Chemical polishing-plastic injection mold polishing

The basic principle of chemical polishing is to get a smooth plane by dissolving the microscopic convex part of the surface preferentially to the concave part through the substance in the chemical medium.

This method has a very good polishing effect for the complex shape of the workpiece, and can also complete the polishing of multiple workpieces, with high efficiency.

Electrolytic polishing-plastic injection mold polishing

The basic principle of electrolytic polishing is similar to chemical polishing, both through the selective dissolution of the material surface tiny projections, to achieve the purpose of surface smoothness.

Compared with chemical polishing, it has a good effect on eliminating cathodic reactions.

Ultrasonic polishing-plastic injection mold polishing

Ultrasonic polishing, is the use of tool section for ultrasonic vibration, through the abrasive suspension polishing brittle hard material a processing method.

Ultrasonic field into the workpiece with abrasive suspension, through the ultrasonic vibration effect so that the abrasive in the workpiece surface grinding polishing.

Ultrasonic processing macro force is small, will not cause deformation of the workpiece, but the disadvantage is that the tooling production and installation are more difficult.

Fluid polishing-plastic injection mold polishing

Fluid polishing, mainly relies on the flow of liquid and the abrasive particles carried to wash the surface of the workpiece to achieve the purpose of polishing.

Fluid power grinding is driven by hydraulic pressure, the medium is mainly used in the lower pressure flow through a good special compound and mixed with abrasives made, abrasive can be used silicon carbide powder.

Magnetic grinding and polishing-plastic injection mold polishing

Magnetic grinding and polishing, mainly using the magnetic field conditions, the formation of abrasive brushes, the surface of the workpiece grinding process.

The advantage of this method is that the processing efficiency is high, the quality is good, and the processing conditions are relatively easy to control.

EDM ultrasonic compound-polishing plastic injection mold polishing

In order to improve the speed of surface polishing, often use the compound polishing method to polish the surface of the workpiece, that is, by ultrasonic vibration and electric pulse corrosion simultaneously on the surface of the workpiece, can quickly reduce its surface roughness.

This method for mold rough surface polishing effect is very obvious.

Besides What are the 7 Plastic Injection Mold Polishing Techniques article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept