Do you know the principles of mold design parting?

Through the communication with mold designers, we summarized the 10 main guidelines of the principles of mold design parting. Although these guidelines in mold parting design may not all meet, or even conflict, they do put forward from different aspects of the mold design parting surface design should meet the requirements.

The principles of mold design parting 1. Consideration of clamping force

The lateral clamping force of the injection mold is relatively small, so for large products with large projection area, the direction with large projection area should be put on the front and back mold opening and closing direction, while the side projection area is smaller as the lateral parting.

The principles of mold design parting 2. Meet the requirements of product release

The parting surface is also for the product to be taken out of the injection mold smoothly. Therefore, the location of the parting surface should be chosen at the part with the largest cross-sectional size, which is the most basic principle.

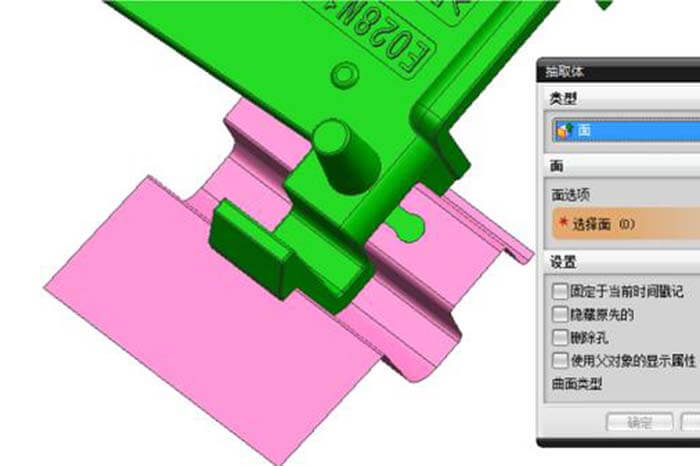

The principles of mold design parting 3. The shape of parting surface

For general products, a parting surface perpendicular to the opening direction of the injection molding machine is often used, while other shapes of parting surfaces are used in special cases. The shape of the parting surface is based on the principle of convenient processing and mold release. For example, if a product is bent, the parting surface should be shaped according to its curvature.

The principles of mold design parting 4. Ensure the appearance and quality of the product

The parting surface should not be chosen on the smooth outer surface of the product. Generally speaking, the appearance of the surface is not allowed to have lines and other lines that affect the appearance of the product; some products with concentricity requirements, the concentricity requirements of all parts of the same side, so as to ensure its concentricity.

The principles of mold design parting 5. Determination of orientation

When deciding the orientation of the product inside the mold, the selection of the parting surface should try to prevent the product from forming side holes or side buckle bits and should avoid using a complex mold structure.

The principles of mold design parting 6. Facilitate the release of the mold

In general, the release mechanism of the injection mold is in the moving mold, so the parting surface should be chosen so that the product stays in the moving mold as much as possible after the injection mold is opened. Therefore, for some places that may stick to the fixed mold, we often add the fixed mold auxiliary release mechanism.

The principles of mold design parting 7. Consider lateral mold opening distance

Generally, the distance of lateral mechanical mold opening is relatively small. Therefore, when choosing the parting surface, the direction of the long core distance should be chosen in the direction of the front and rear mold opening and closing, and the short direction should be used for the lateral parting.

The principles of mold design parting 8. Easy processing of mold parts

When choosing the parting surface, the injection mold should be divided into parts that can be easily processed to reduce the difficulty of machining.

The principles of mold design parting 9. Easy to exhaust

When the parting surface is used as the main exhaust, the parting surface should be designed at the end of the plastic flow to facilitate the exhaust.

The principles of mold design parting 10. R parting

For mold design parting many products, there is a whole circle of R angle at the parting surface, then the parting has to consider the R best parting, cannot appear sharp side.

Besides The 10 Principles of Mold Design Parting article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept

18 FAQ Of Injection Molding Machine Mold Clamping