Description

What is Spring Pin Tension Pin Coll Pin?

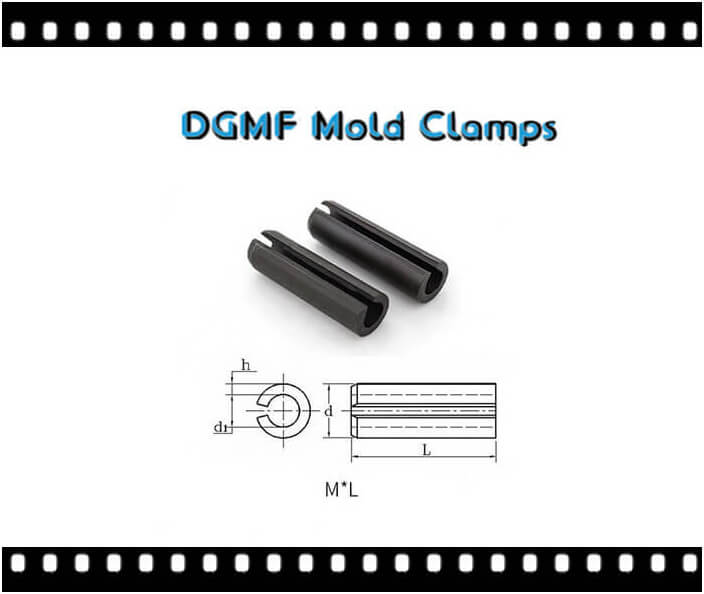

A spring pin (also called tension pin or roll pin) is a mechanical fastener that secures the position of two or more parts of a machine relative to each other.

Spring pins have a body diameter that is larger than the hole diameter, and a chamfer on either one or both ends to facilitate starting the pin into the hole. The spring action of the pin allows it to compress as it assumes the diameter of the hole. The force exerted by the pin against the hole wall retains it in the hole, therefore a spring pin is considered a self-retaining fastener.

Spring pins may be used to retain a shaft as a journal in a plain bearing, as a type of key to fasten one shaft to another, or to precisely fasten flat faces of mating parts together through symmetric hole locations.

Types

There are two types of spring pins: slotted spring pins and coiled spring pins.

Coiled spring pins

A coiled spring pin, also known as a spiral pin, is a self-retaining engineered fastener manufactured by roll forming metal strip into a spiral cross-section of 2 1⁄4 coils. Coiled spring pins have a body diameter larger than the recommended hole diameter and chamfers on both ends to facilitate starting the pin into the hole, the spring action of the pin allows it to compress as it assumes the diameter of the hole. Often referred to as a spiral pin in the Midlands.

When coiled spring pins are installed, the compression starts at the outer edge and moves through the coils toward the center. Coiled pins continue to flex after insertion when a load is applied to the pin thus providing excellent performance to counter fatigue in dynamic applications.

Coiled pins are commercially available in three different duties, standard (ISO 8750), heavy (ISO 8748), and light-duty (ISO 8751), which provide for a variety of combinations of strength, flexibility, and diameter to suit different mating host materials and performance requirements. Typical materials for coiled spring pins include high carbon steel, stainless steel, and alloy 6150.

Coiled pins are used extensively in cosmetic cases, automotive door handles and locks, and latches as hinge pins. They are also used as pivots and axles, for alignment and stopping, to fasten multiple components together—such as a gear and shaft—and even as ejector pins to remove motherboards from PCs. The automotive and electrical industries use coiled pins in such products as steering boxes and columns, pumps, electric motors, and circuit breakers.

International Standards

Standard Duty: UNE–EN-ISO 8750, NASM10971, NASM51923, NAS1407, ASME B18.8.2, ASME B18.8.3M

Heavy Duty: UNE–EN-ISO 8748, NASM10971, NASM39086, NAS561, ASME B18.8.2, ASME B18.8.3M

Light Duty: UNE–EN-ISO 8751, NASM10971, NASM51987, NAS1407, ASME B18.8.2, ASME B18.8.3M

Standard duty coiled spring pins offer the best balance between flexibility and strength and are recommended for most applications.

Heavy-duty coiled spring pins are typically used in high shear strength applications and hardened host materials.Light duty pins are used in applications with soft metals and plastics holes where there is a high risk of enlarging or breaking the host using a traditional press fit solid pin.

Coiled spring pin as an alignment pin in aluminum castings

A coiled spring pin secures the lift lever relative to the valve rod

Slotted spring pin

Slotted spring pins are cylindrical pins rolled from a strip of material with a slot to allow the pin to have some flexibility during insertion. Slotted spring pins are also known as roll pins, Selleck pins, or “C” pins.

Material

1. A3 carbon steel (not commonly used, no hardness)

2.50 manganese steel (used for small elastic pins, with better strength and toughness)

3.65 manganese steel (spring steel, high elasticity after quenching, small stress relaxation, large spring pin use)

4.60 silicomanganese (good strength, good elasticity, good stability against tempering, suitable for high-temperature environment)

5. Stainless steel 304 (no rust, low hardness)

6. Stainless steel 410 (quenchable, high hardness, magnetic)

7. Other materials

Production process

Feeding (with the material)-cutting (opening into pieces of the corresponding size according to the specifications)-upper die-roll finished product-heat treatment-electroplating-testing-packaging and shipping.

There are two processes for this, one is a one-time direct molding, this kind of quality is better, more convenient to use, no burrs, etc. The cost of this kind of mold is relatively high, and the advantage is that one mold can produce products with different specifications and lengths.

The other is traditional pin processing, basically one mold per specification, but the mold is cheap. After the pin coiling is completed, the chamfer is processed twice.

Series

1. GB879-76, GB879-86 standard spring pin;

2. Slotted spring pin, special rod for heel;

3. GB879-3, GB879-2000 multi-turn spring pin;

4. Flexible sales in English, Japanese, German, American, etc.;

5. The above product materials can be manganese steel or stainless steel or other materials specified by the customer.

Specifications φ1-φ50.

Cylindrical pin series

1. GB119 cylindrical pin;

2. GB120 internal thread cylindrical pin;

3. 117 taper pin;

4. 118 taper pin with internal thread;

5. 880 pins with holes

The above products can be made of carbon steel or stainless steel or other materials specified by customers.

Specifications φ1-φ50.

Classification

1) Light spring pin

2) Heavy spring pin

The main difference between light type and heavy type is the thickness of the material and the width of the chamfer. The thickness of the heavy spring pin material and the width of the chamfer are larger than that of the light type.

Slotted spring pin

1) Lightweight slotted spring pin

2) Heavy-duty slotted spring pin

Similar to ordinary elastic cylindrical pins, the difference lies in the shape of interlaced wavy teeth at the axial slot.

Coiled spring pin

1) Lightweight coiled spring pin

2) Heavy-duty coiled spring pin

Material and its mechanical properties

1) Carbon spring steel

2) Stainless steel

Standard

1) GB/T 879.2-2000

2) ISO 8753

3) JIS B 2808

4) DIN 7346

5) ASME B18.8.2

6) Other national or industry standards

Common size

1) Diameter M1.5 M2 M2.5 M3 M4 M4.5 M5 M6 M8 M10 M12 M16 etc.

2) Length 4 5 6 8 10 12 14 15 16 18 20 22 25 26 28 30 32 35 36 38 40 etc.

Spring pin belongs to a kind of hardware product of pin shaft that can be used repeatedly and can be adjusted appropriately. The production of spring pins is actually made by rolling them with a flat plate. Put the spring pin in the hole. When the pin is subjected to external pressure, the spring pin will be compressed. When the pressure is eliminated, it will return to its original state, and finally, play a role in positioning.

How to install the spring pin?

The operation when installing the spring pin is also very convenient. It can be installed directly with a hammer. We only need to pay attention to the direction of the slot of the elastic pin to be consistent with the force direction of the part. After the installation is in place, the spring pin should After being buried in the substrate, it is level with the surface.

After the spring pin is installed, it is difficult to loosen, and the accuracy of the guide hole is not high. The first thing with a good quality spring pin is that its hardness is harder, and then its elasticity is better.

If it is a black spring pin, its material is mostly made of 65Mn spring steel. If it is a stainless steel elastic pin, use SUS304 material, but the elasticity of the stainless steel elastic pin must be slightly worse. This is not a quality problem, but the characteristics of the raw material. in this way.

When measuring the size of a spring pin, its diameter should be larger than the specifications we described. For example, if the size of the spring pin we require is 4×20, then 4 means the diameter of 4 mm, and 20 means the height of the spring pin is 20. Mm. When we are measuring, its diameter will be 4.2 to 4.3 mm, which is conducive to this higher tolerance just after the spring pin is installed, it will not loosen.

The installation notes

1. The spring pin is assembled with a hammer;

2. When the spring pin is assembled with the external pin and the internal pin, the pinholes should be wrong;

3. When the spring pin is assembled, the direction of the pin opening should be consistent with the direction of the workpiece;

4. After the spring pin is assembled into the workpiece, the pin should be assembled in place, basically flush with the surface of the workpiece.

Reviews

There are no reviews yet.