Fasteners

-

Three In One Multi-functional Combination Eyebolt For Lifting

Read more -

Threaded Rod Extension Nuts

Read more -

T Slot Bolts

Read more -

T Bolts For Milling Machine

Read more -

T Bolts And Nuts

Read more -

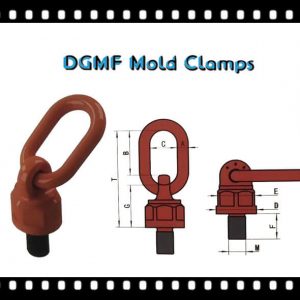

Swivel Eye Bolt For Lifting

Read more -

Stainless Steel Knurled Phillips Thumbscrews

Read more -

Stainless Steel Knurled Flat Head Thumbscrew

Read more -

Stainless Steel Hexagonal Stud Bolts With Right Hand Left Hand Threaded

Read more -

Stainless Steel 304 Left Hand Threaded Rod

Read more -

Spring Pin Tension Pin Coll Pin

Read more -

Self-Clinching Fasteners Spring-loaded Captive Panel Screws

Read more -

Self-clinching Blind Fasteners Blind Press Nuts

Read more -

Sefl-clinching Fasteners Captive Panel Screws

Read more -

Scrap Breakers for Cam Pierce Dies CPSBR Srew Plug

Read more -

Saw Blade Bolt Left-hand Screw

Read more -

No-Twist Mold Washer

Read more -

Mold Clamping Stud With Spanner

Read more -

Mold Clamp Washers

Read more -

Milling Machine T-Slot Nuts

Read more -

Lifting shackles Bow Dee and Safety Pin Shackles

Read more -

Lifting Eyebolts Screw Type Lifting Points

Read more -

Lifting Eye Nuts DIN 582

Read more -

Knurled Head Thumb Screws With Shoulder

Read more -

Jack Nuts Petal Nuts Threaded Insert Screw Anchors

Read more -

High-Pressure Plugs Tapered Screw Plugs

Read more -

Heavy-duty Machinist Screw Jacks For Lifting Molds

Read more -

Heavy Hex Nuts

Read more -

Forged Flange Nuts

Read more -

Forged and Hardened Mold Clamping Stud

Read more -

Forged and Hardened Mold Clamp Bolts

Read more -

Floating Nut

Read more -

Extra Long Coupling Nuts

Read more -

DIN 508 T Nuts For Milling Machine

Read more -

DIN 25201 Double Stack Self-locking Washers

Read more -

Clevis Pins Fastenal Cotter Pin Fitting For Locking

Read more -

Chicago Binding Screws Sex Bolt

Read more -

CD Weld Standoffs

Read more -

Ball Screw Set Smooth Ball Plunger Spring Plunger

Read more -

Ball Plungers Ball Nose Spring plungers

Read more -

12.9 Grade Square Head T Bolt

Read more

Fasteners Supplier

DGMF Mold Clamps Co., Ltd is the bolts, nuts, washers, fasteners supplier, and mould clamps manufacturer in China.

What are fasteners?

Fasteners are the general term for a type of mechanical parts used when two or more parts (or components) are fastened and connected into a whole.

Fastener Applications

Fasteners are a type of mechanical parts that are used for fastening connections and are extremely widely used. All kinds of fasteners can be seen in all kinds of machinery, equipment, vehicles, ships, railways, bridges, buildings, structures, tools, instruments, meters, and supplies.

It is characterized by a wide variety of specifications, different performance and uses, and a high degree of standardization, serialization, and generalization. Therefore, some people call a type of fasteners that have national standards standard fasteners, or simply standard parts.

Fasteners are the most widely used mechanical basic parts.

With my country’s accession to the WTO in 2001, it has entered the ranks of major international trading nations. my country’s fastener products are exported in large quantities to countries around the world, and fastener products from all over the world are also pouring into the Chinese market.

Fasteners, as one of the products with a large import and export volume in my country, are in line with international standards. It is of great practical significance to promote Chinese fastener companies to the world and promote fastener companies to fully participate in international cooperation and competition. Strategic significance.

Because of the specifications, dimensions, tolerances, weight, performance, surface conditions, marking methods of each specific fastener product, as well as the specific requirements for acceptance inspection, marking, and packaging.

Common fastener testing equipment

The most important link in the development and design of fasteners is quality control. There are several major barriers from input to finished product shipment. These major barriers have different inspection methods.

First of all, the input materials are related to appearance, size, element, performance, hazardous substance detection, etc.;

The process is more about appearance, size, percussion experiment, forging streamline;

Heat treatment is more about appearance, hardness, torque, tension, metallography, etc.;

The surface treatment is more about hydrogen embrittlement tests, coatings, salt spray, etc., including a hazardous substance test when shipped.

In terms of size and appearance inspection, the common ones are the two-dimensional, contour measuring instrument, three-coordinate measuring instrument, and image sorting machine (this is a full-selection machine);

In mechanical and chemical testing, there are mainly hardness machines (Rockwell and Vickers), tensile machines, and metallurgical microscopes;

For material testing, there is a spectrum analyzer and salt spray tester.

Fastenal Components

It usually includes the following 12 types of parts

Bolts

A type of fastener consisting of a head and a screw (cylinder with external thread), which needs to be matched with a nut to fasten and connect two parts with through holes. This type of connection is called the bolt connection. If the nut is unscrewed from the bolt, the two parts can be separated, so the bolt connection is a detachable connection.

Nuts

A nut is a part that is screwed together with a bolt or screw for fastening. A component that must be used in all manufacturing machinery is divided into carbon steel, stainless steel, non-ferrous metals (such as copper), and other major types according to different materials.

Studs

There is no head, only a type of fastener with threads on both ends. When connecting, one end of it must be screwed into the part with an internally threaded hole, the other end must be passed through the part with a through-hole, and then the nut is screwed on, even if the two parts are tightly connected as a whole.

This type of connection is called a stud connection, which is also a detachable connection. It is mainly used where one of the connected parts has a large thickness, requires a compact structure, or is not suitable for bolt connection due to frequent disassembly.

Screws

It is also a type of fasteners composed of two parts, a head and a screw, which can be divided into three categories according to their uses: machine screws, set screws, and special purpose screws.

The machine screw is mainly used for a tightening connection between a part with a threaded hole and apart with a through-hole, without the need for a nut to fit (this connection form is called a screw connection, which is also a detachable connection; Cooperate with nut, used for fastening connection between two parts with through holes.).

The set screw is mainly used to fix the relative position between the two parts. Special purpose screws such as eyebolts are used for lifting parts.

Nut: With internally threaded holes, the shape is a generally flat hexagonal cylinder, and also a flat square cylinder or flat cylinder. With bolts, studs, or machine screws, it is used to fasten and connect two parts to make it One piece whole.

Self-tapping screws

Similar to machine screws, but the thread on the screw is a special self-tapping screw thread.

It is used to fasten and connect two thin metal components into a whole. Small holes need to be made in the component in advance. Because this kind of screw has high hardness, it can be directly screwed into the hole of the component to make the component form a responsive internal thread

Wood screws

It is also similar to a machine screw, but the thread on the screw is a special wood screw thread, which can be directly screwed into the wooden component (or part) to use a metal (or non-metal) with a through-hole.

The parts are firmly connected to a wooden component. This connection is also a detachable connection.

Washers

A type of fastener with an oblate ring shape.

Placed between the support surface of bolts, screws, or nuts and the surface of the connected parts, it plays a role in increasing the contact surface area of the connected parts, reducing the pressure per unit area, and protecting the surface of the connected parts from being damaged;

Another type of elastic washer can also prevent the nut from loosening.

(Circlip) Retaining rings

It can be installed in the shaft groove or shaft hole groove of the machine and equipment to prevent the parts on the shaft or hole from moving left and right.

Pins

Mainly used for positioning the left and right parts, and some can also be used for connecting parts, fixing parts, transmitting power, or locking fasteners.

Rivets

A type of fastener consisting of a head and a nail shaft used to fasten and connect two parts (or components) with holes to make them into a whole.

This connection form is called rivet connection, or riveting for short. It is a non-detachable link. Because if the two connected parts are separated, the rivets on the parts must be broken.

Components and connection pairs

(Combination bolts w/washer & spring washer or others)

Assemblies are a type of fasteners supplied in combination, such as a combination of machine screws (or bolts, self-supplied screws) and flat washers (or spring washers, lock washers);

Connection sub means a type of fastener supplied with a combination of a certain special bolt, nut, and washer, such as a high-strength large hexagon head bolt connection pair for steel structures.

Welding nails

heterogeneous fasteners composed of nail rods and nail heads (or no nail heads), which are fixedly connected to a part (or component) by welding so as to be connected with other parts.

Fastener Processing

Lock up

Fasteners include bolts, studs, screws, nuts, washers, and pins.

Locking or seizure often occurs on fasteners made of stainless steel, aluminum alloy, and titanium alloy. These metal alloys have anti-corrosion properties. When the surface is damaged, a thin oxide layer is formed on the metal surface to prevent further corrosion.

When stainless steel fasteners are locked, the pressure and heat generated between the teeth will destroy this oxide layer, causing blockage or shearing between the metal threads, and then adhesion.

When this phenomenon continues, the stainless steel fasteners will be completely locked and can no longer be removed or continued to be locked.

Usually, this series of blocking, shearing, adhering, and locking actions occur in just a few seconds, so a correct understanding of the use of such fasteners can prevent this phenomenon.

1. Choose the right product

A. Before use, confirm whether the mechanical properties of the product can meet the use requirements, such as the tensile strength of the screw and the guaranteed load of the nut. The length of the screw should be selected appropriately, which shall be subject to 1-2 pitches of the exposed nut after tightening.

B. Before use, check whether the threads are rough and whether there is iron filings or dirt between the threads. These things often cause a lockup.

C. The fasteners can be lubricated before use. It is recommended to use butter, molybdenum disulfide, mica, graphite, or talc for lubrication, and generally use wax dipping for lubrication and anti-locking.

2. Pay attention to the method of use when using

A. The speed and force of screwing in should be appropriate, not too fast or too big. Use torque wrenches or socket wrenches as much as possible, and avoid using adjustable wrenches or electric wrenches. Too fast will cause the temperature to rise rapidly and cause a lockup.

B. In the direction of force, the nut must be screwed in perpendicular to the axis of the screw.

C. The use of washers can effectively prevent the problem of over-locking.

Fastener Standards

Stainless steel fastener product size standards: specify the content of the basic product size; threaded products.

Not standard on product technical conditions. Specifically, it includes the following standards

Standards for fastener product tolerances: specify product size tolerances and geometric tolerances.

Standards for mechanical properties of fastener products

Specify the marking method of product mechanical performance level and the content of mechanical performance items and requirements;

Some fastener products change this content to the content of product material performance or work performance.

Standards for surface defects of fastener products

Specify the types of product surface defects and specific requirements.

Standards for surface treatment of fastener products

Specify the types and specific requirements of product surface treatment.

Standards for fastener product testing

Specifically, specify the content of the above-mentioned various performance requirements test.

Standards for product acceptance inspection, marking, and packaging of stainless steel fasteners

Standards for marking methods of fastener products

Specify the complete and simplified marking methods for products.

Other standards for stainless steel fasteners

Such as fastener terminology standards, fastener product weight standards, etc.

Mechanical industry

The machinery industry is one of the main users of fasteners.

Due to China’s late understanding of the important position of mechanical basic parts in the machinery industry, and a long-term lack of investment, the entire industry has a poor foundation, weak foundation, and weak strength.

Especially with the improvement of the level of China’s mainframe, the bottleneck phenomenon of mechanical basic parts lagging behind the mainframe has become increasingly apparent.

Nowadays, although the state has given certain support in terms of technology introduction, technological transformation, scientific research, and development, there is still a big gap compared with the current market demand and foreign levels.

The specific manifestation is that the product variety is small, the level is low, the quality is unstable, the early failure rate is high, and the reliability is poor.

Fasteners are the main basic products in the machinery industry, and the development of the machinery industry also puts forward higher requirements for fastener products.

Domestic common standard fasteners have always been in oversupply, while high-end fasteners (fasteners with high temperature, special-shaped, titanium-plastic composite, special performance, etc.) are in short supply, and they have to rely on imports.

With the improvement of national industrialization level and technological progress, the use of high-strength fasteners has gradually increased.

High-strength automotive fasteners

A total of 13 domestic automotive fastener companies were visited and investigated in this survey, and all the companies surveyed have passed the TS16949 system certification.

On average, there are about 1500 fasteners for a car, and the total time for bolt assembly for each car is about 2.5~3.2h. It can be seen that the variety and quality of fasteners have an important impact on the level of the host and the quality of the vehicle.

This article analyzes the localization of high-strength threaded fasteners and the management of supply quality from the manual process of the production of high-strength threaded fasteners.

Product process of high-strength threaded fasteners The production process of high-strength threaded fasteners is raw material reformation → cold heading forming → thread processing (thread rolling or thread rolling) → heat treatment → surface treatment → sorting and packaging, generally used above 10.9 Thread rolling process after heat treatment.

The commonly used steel grades for high-strength bolts of automotive fastener materials are 35 steel, 45 steals, and ML35 steel for grade 8.8 bolts; 35CrMo; 40Cr for grade 10.9 bolts; 35CrMo, 42CrMo, and SCM435 for grade 12.9 bolts.

The raw materials for domestic fasteners are basically hot-rolled, while the steel for fasteners produced in Japan and other countries can basically be directly cold-headed. Users do not need pretreatment, which can reduce costs in terms of links.

The common failure modes of fastener failure include assembly elongation, fatigue fracture, and delayed fracture.

The quality of cold heading forming and thread processing (thread rolling or thread rolling, tapping) threaded fasteners, in addition to materials, forming equipment, thread processing equipment and molds (production processes and equipment) are key factors to ensure their quality.

Especially in the supply of large quantities of multiple varieties, how to ensure the consistency of the products and the prevention of defects for automotive fasteners that require high processing accuracy is one of the problems faced by the fastener production.

Of the cold heading equipment and thread processing equipment of the company under investigation, domestic equipment accounted for about 40%, Taiwan equipment accounted for 50%, and imported (Europe, America, Japan) equipment accounted for about 10%;

Common defects include size and shape tolerance, head folding, thread streamline upsetting, tooth wrinkles, and cracks.

Due to capital or other reasons, domestic fastener factories mostly use domestic equipment and Taiwan equipment to produce automotive fasteners. To ensure the dimensional tolerance and shape tolerance of high-end fastener products in large-scale production, online monitoring should be increased. Means and mold making level.

Eliminate substandard products in production, thereby ensuring the assembly quality of OEMs and automakers.

About 80% of the fastener companies surveyed have heat treatment equipment, and most of them use Taiwan’s heat treatment process line; the process line equipment is a continuous mesh belt furnace with atmosphere protection, and the atmosphere, temperature, and process parameters are controlled by a computer.

The high-strength fastener industry is a relatively competitive industry. To have a thorough and objective analysis of the technology and market of the high-strength fastener industry, we need to start from the following aspects

The competitive landscape of domestic high-strength fasteners industry enterprises, high-strength fastener industry industrial policies, technical standards, and regulations for high-strength fastener products, the competitive landscape of high-strength fastener products in China Firmware product core technology research and development trends Regarding these six aspects, many domestic research institutions have conducted in-depth investigations and studies, and many institutions have long been engaged in research and research in the industry.

Fastener Industry-standards

Fastener National standards

1. The standard of fastener product size: specify the content of the basic size of the product; for the threaded product, it also includes the basic size of the thread, thread end, shoulder distance, undercut and chamfer, and the end of externally threaded parts dimensions and other aspects.

2. Standards on technical conditions of fastener products. Mainly include product tolerances, mechanical properties, surface defects, surface treatment, product testing standards, and corresponding specific provisions.

3. Standards for screw product acceptance inspection, marking, and packaging: specify the qualified quality level and sampling plan of the random inspection items during the factory acceptance of the product, as well as the content of the product marking method and packaging requirements.

4. Standards for marking methods of standard parts, fasteners, screws, and screws: specify the complete marking method and simplified marking method of the product.

5. Other standards of fasteners: such as the standard of fastener terminology and the standard of fastener product weight.

DGMF Mold Clamps Co., Ltd manufactures the mold clamps, and supplies the injection mold components, such as Clamps, Toggle Clamps, C Clamps, Pins, Bushings, Positioning Components, Lock Mold Components, Reset Extrusion, Cavity, and Core Components, Coolings, Die Press Components, Punch And Die, Guide Components, Self-lubricating Components, Springs, Machine Tools, Gate Valves, Machine Mounts, Vises, Fasteners, Lifting, Bolts, Nuts, Washers, etc.

Contact the DGMF Mold Clamps teams for more details about the fasteners such as fasteners specifications, fasteners pricing, fasteners inventory, etc.