Description

Clevis Pins Fastenal Cotter Pin Fitting For Locking

What is a clevis pin?

A Clevis pin is a type of fastener that allows rotation of the connected parts, it consists of a head, shank, and hole, the hole passes through the shank at the opposite end of the pin from the head.

A clevis pin is a fastener that has a head on one end and a hole through the other end of the body for fitting a cotter pin for locking.

Clevis pins are one of the components of a three-piece clevis fastener system. Clevis pins are used as a quick and secure fastener in place of bolts and rivets.

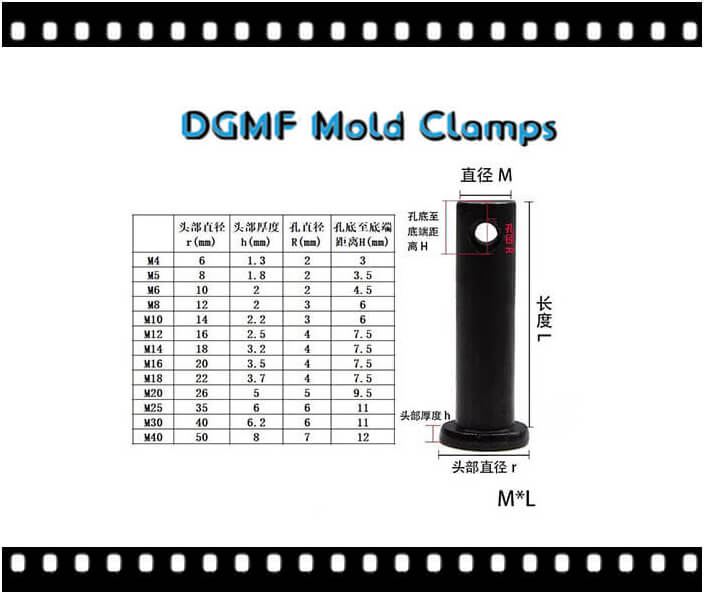

Clevis pin drawing and specifications

Designed with both a flat or domed head on one end and a cross-hole at the other, a clevis pin is inserted through the holes at the pronged ends of a clevis and is kept in place by a cotter pin.

Similar to bolts and rivets, clevis pins are used as quick, secure, and cost-effective fasteners; however, they can hold much more load tension of pulling forces when connecting two structural units. Clevis pins are an essential closure for anchor and chain shackles.

When threaded through the prongs of a tang and secured with a cotter pin, a clevis pin can be used to hitch farm and construction equipment for towing. Designed to absorb lateral stress, clevis pins are flanged at one end, with holes at the other end for receiving cotter pins.

Clevis pins are used as a quick and secure fastener in place of bolts and rivets. Clevis Pin cost-effective fastening solution from DGMF, Made of solid material with a hole, Provides freedom of movement for support of the objects.

Clevis pins are used in the automotive and aircraft industry as well as sailboat riggings. They are typically made of stainless steel and come in many sizes; units of measure can be metric or inches.

The U-shaped fastener has holes at one end of the prongs, in which the stainless steel clevis pin is inserted. Once inserted a split pin securely holds the clevis fastener in place. There are other kinds of pins that do similar jobs like cotter pins and hitch pins; choose the one that best fits your needs.

The pin is a material used in the machine. The biggest function is to help the built-in fixed point in the machine, and at the same time play the role of connecting and fixing. According to the shape, the pins can be divided into split pins, clevis pins, spring pins, and keys, and their functions are different.

Pin function

In short, a pin is a connecting piece, and sometimes it also plays the role of positioning and fixing. The pin generally adopts the press-in method or the soft metal knock-in method.

According to the nature of the connection, the pin can be divided into a rigid pin and an elastic pin. The rigid pin is connected and cannot be moved, and the elastic pin is left with a certain range of relative movement.

When connecting the pins, you need to pay attention to the bearing capacity. Because the cross-section of the pin is relatively small, it is not suitable to use the pin when the transmission load is large.

When using positioning pins, attention should be paid to the matching accuracy. Simply put, first determine the position of the part, then make a few holes in the part and insert the positioning pin. Then put on other parts to ensure that they can’t move within a certain range, then the positioning is successful. If the set is swayed or cannot be set, then it means the positioning has failed.

Pin types

(1) Split pin

The cotter pin is mainly used for fixing between screws. Generally, the cotter pin is inserted into the nut groove and the bolt tail hole during use, and the tail of the cotter pin is opened to prevent the relative rotation of the nut and the bolt. . In order to avoid damage to the hole wall, grease can be added to the pinhole during use.

(2) Clevis pin

The clevis pin is a kind of pin used for the connection and fixation between different equipment. It is generally installed in the parts that need to be removed frequently. The clevis pin has a taper of 1:50 and has the advantages of good self-locking, convenient installation, and simple disassembly.

(3) Spring pin

The spring pin is a pin mainly used for positioning or connection and is fixed in the pinhole by fitting. Cylindrical pins used for positioning are usually not subject to load or small load, and the number is not less than two. They are distributed in the symmetrical direction of the overall structure of the connected parts. The farther the distance, the better. Spring pins are currently made of high-quality carbon structural steel as raw materials, but heat treatment is required to strengthen their hardness and improve their performance.

(4) Key

Key is a kind of pin widely used in machinery and electricity. As a connecting fastener, many details need to be paid attention to when installing and connecting. If the connection of the key pin is not done well, the performance of the groove pin cannot be released, resulting in poor use of the groove pin.

Pin performance

The pin is to connect two unrelated things together and play a fixed role. According to the use and performance, it can be divided into rigid pins and elastic pins.

(1) Elastic pin

The elastic spring pin is made up of the outer edges of the flanges of the two half couplings and the inner edge of the outer sleeve into semi-element-shaped grooves with the same radius, which is combined into a pinhole to embed the pin. With a certain range of relative movement, it is very suitable for use in non-stop machinery, which can reduce material wear.

(2) Rigid pin

The rigid pin is mainly used for fixing and connecting, so two parts can be connected. However, high-end stainless steel is generally used for the material of the pin, which has good waterproof performance, is not easy to rust, and has a longer service life.

How to install a pin?

1. The pin of the elastic sleeve pin coupling is covered with a rubber ring, which has elasticity and the ability to compensate the axis displacement, but when the relative angular displacement is large, it is easy to wear;

2. Simple structure, convenient installation, easy replacement, small size, lightweight, large transmission torque, widely used in various rotary pumps;

3. The allowable relative radial displacement is 0.14-0.2mm; the allowable relative angular displacement is 0 degrees 40 minutes;

4. The additional radial load caused by the relative displacement of the two shaft axes is (0.1-0.3)P;

5. The standard of the water pump industry is Bll01, its maximum allowable torque is 8316Nm, and the maximum shaft diameter is 200mm.

Reviews

There are no reviews yet.