How To Deal With Sink Marks On The Surface Of Injection Molded Products?

Noun explanation

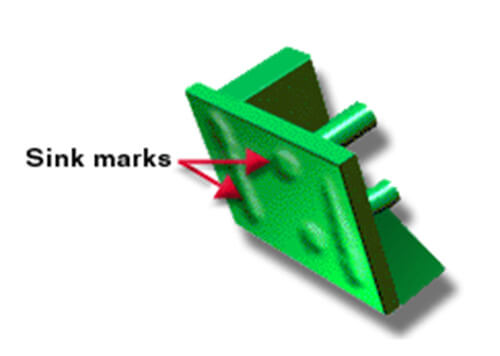

Uneven product wall thickness causes uneven surface shrinkage and sinks marks.

Failure analysis and troubleshooting methods

Improper control of molding conditions.

Properly increase the injection pressure and injection speed, increase the compression density of the melt, extend the injection and pressure holding time, compensate for the shrinkage of the melt, and increase the injection buffer volume. But the holding pressure cannot be too high, otherwise, it will cause bumps.

If dents and sink marks occur near the gate, they can be solved by extending the holding time;

When the plastic part has a depression in the wall thickness, the cooling time of the plastic part in the mold should be appropriately extended;

If the dents and sink marks around the insert are caused by the partial shrinkage of the melt, this is mainly caused by the temperature of the insert being too low, try to increase the temperature of the insert;

If the surface of the plastic part is sunken due to insufficient material supply, the amount of material supplied should be increased. In addition, the cooling of the plastic part in the mold must be sufficient.

Mold defects.

According to the specific situation, appropriately expand the gate and runner cross-section, and set the gate position as symmetrically as possible, and the feed port should be set in the thick wall of the plastic part.

If dents and sink marks occur far away from the gate, it is generally due to poor flow of melt in a certain part of the mold structure, which hinders pressure transmission.

In this regard, the structural size of the mold gating system should be appropriately expanded, and it is best to extend the runner to the recessed part. For wall-thick plastic parts, wing gates should be preferred.

The raw materials do not meet the molding requirements.

For plastic parts with relatively high surface requirements, resins with low shrinkage rates should be used as much as possible, and an appropriate amount of lubricant can also be added to the raw materials.

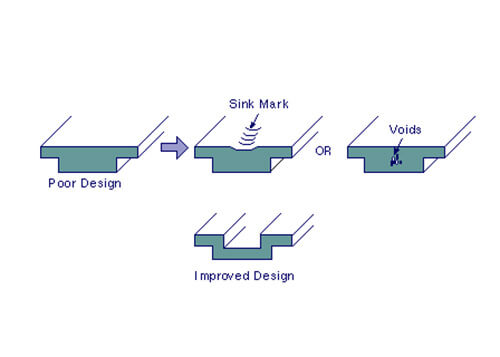

The shape and structure design of plastic parts is unreasonable.

When designing the shape and structure of plastic parts, the wall thickness should be as consistent as possible. If the wall thickness of the plastic part is different, it can be solved by adjusting the structural parameters of the gating system or changing the wall thickness distribution.

Figure 2 Changing the wall thickness to reduce sink marks

You may also be interested in the below articles:

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams