Uneven shrinkage in plastic parts often results in uneven distribution of internal stress. If this stress exceeds the stiffness of the plastic part, it will cause warpage and distortion and affect the dimensional stability of the plastic part.

Uneven shrinkage in plastic parts has four main reasons.

Uneven shrinkage in plastic parts reasons 1. Different melt temperatures.

Melting temperature is high shrinkage

Uneven shrinkage in plastic parts reasons 2. Different cooling speed

Fast cooling < slow cooling (reason: slow cooling molecules have time to arrange, so the shrinkage is large)

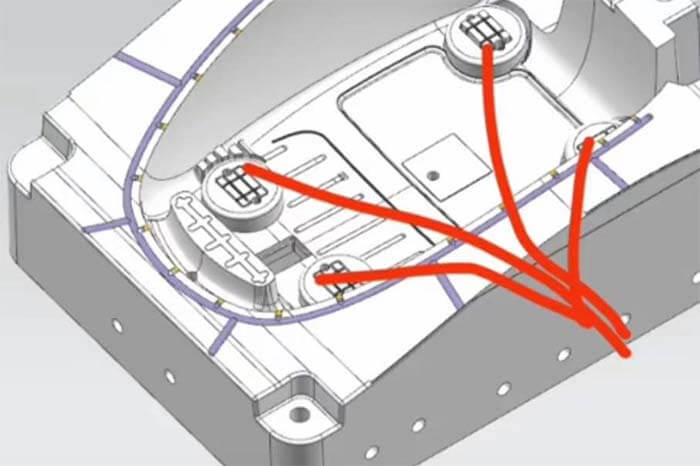

Uneven shrinkage in plastic parts reasons 3. The different flow directions of melt glue (amorphous material) (anisotropy).

In short, the tensile stress is high along the flow direction, so the shrinkage is high. In the filling process of plastic, due to flow orientation, the molecular chains are aligned.

The polymer chains are aligned in the flow direction and vertical flow direction by the stretch situation is different, so the shrinkage behavior is also different. This is called directional shrinkage.

Generally speaking, the in-flow shrinkage is higher than the cross-low shrinkage. This is because the plastic polymer chains are more stretched in the flow direction and have a greater tendency to return to their unstretched state.

The differential shrinkage caused by the flow orientation often results in a warpage of the plastic part. Therefore, if we can break up the molecular orientation, it will help the uniformity of shrinkage and reduce the warpage caused by directional shrinkage.

Uneven shrinkage in plastic parts reasons 4. Different sizes (differential thermal strain).

The larger the size, the greater the shrinkage.

If the uneven shrinkage in plastic happened, it often causes uneven distribution of internal stress. If this stress exceeds the stiffness of the part, it will cause warpage and distortion and affect the dimensional stability of the part.

Warpage caused by design: wall thickness size

The thicker wall thickness area is more difficult to cool and hold pressure and requires a longer cooling time and poorer pressure retention. After demoulding, it still keeps the local high temperature and continuous cooling.

Therefore, in the thicker part of the flesh, such as the rib, there is a tendency to have local shrinkage that causes dents (sink marks) in the molded part.

For plastic parts with workpiece variation, choosing the pouring position at the thicker part can facilitate pressure-holding, and even if the workpiece is cured, the pressure-holding pressure can still be transferred smoothly to improve the shrinkage phenomenon.

What is Wall thickness variation?

Uniform wall thickness will improve shrinkage. If the wall thickness distribution is uneven, it should be considered whether the difference in shrinkage caused by different cooling and pressure-holding effects will cause warpage of the part, and the stress concentration caused in the wall thickness transition regions.

Stress concentration in the wall thickness transition regions can cause short-term or long-term warpage problems and reduce the mechanical performance of the part. Reinforcing ribs can be introduced to reinforce the structural strength of the part to reduce shrinkage.

The contact between the rib and the wall of the part should be large enough to relieve the stress concentration problem and overcome the flow resistance; however, attention should be paid to the sink mark problem that may be caused.

The size of the dent is also affected by the shrinkage characteristics of the plastic. Under the consideration of strength and stiffness, it is helpful to reduce shrinkage if the flesh thickness of the part can be reduced by hollowing out (core out).

What are the injection molding conditions and deformation?

As the injection molding conditions are related to deformation, we must pay special attention to the injection molding and holding time, cooling time, injection molding speed, and mold temperature.

1. Injection molding and holding time

The sum of injection molding and holding time should be designed to be longer than the gate closing time. If it is shorter than the gate closing time, sometimes the deformation increases.

2. Injection mold cooling time

A longer cooling time will reduce the deformation.

3. Injection molding speed

Depending on the shape of the molded product, sometimes the deformation is smaller if the injection molding speed is fast, and sometimes the deformation is smaller if the injection molding speed is slow. In the actual molding, the injection molding speed should be changed to find the condition of minimum deformation.

4. Mold temperature

If the mold temperature is low, the deformation of molded products will be small. However, if the molding temperature of the mold is high, it may cause post-shrinkage deformation or dimensional change. The mold temperature should be decided based on these factors.

Besides the What are the Causes of Uneven Shrinkage in Plastic Parts article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept

18 FAQ Of Injection Molding Machine Mold Clamping