How to reduce the cost of injection molding processing? Here are eight ways to reduce the cost of injection molding processing, let us introduce the eight ways to reduce the cost of injection molding processing one by one.

I. How to reduce the cost of injection molding processing in the production workshop?

The layout of the production plant focuses on two aspects: to meet the production demand conditions, according to the production process to optimize the layout at the same time, to meet the specific production conditions of flexible energy requirements.

- Electricity supply, in order to meet the stable production of electricity required at the same time there is an appropriate margin, not too much surplus caused by excessive reactive energy consumption.

- Build efficient cooling water circulation facilities and equip the cooling water system with effective insulation and heat preservation system.

- Optimize the overall production layout of the workshop. Many production processes have sequential cooperation, reasonable cooperation can reduce the time required for turnover and energy consumption, improve production efficiency.

- Consider the lighting and other plant equipment as much as possible to the most effective small unit for separate control.

- Do regular maintenance of workshop equipment to avoid damage to utilities, which may affect normal operation and increase energy consumption.

II. How to reduce the cost of injection molding processing by injection molding machine?

The injection molding machine is a major energy consumer in the injection molding workshop, and the energy consumption is mainly for the motor and heating two parts.

- Choose the right injection molding machine according to the characteristics of the products.

- The use of an all-electric injection molding machine and hybrid injection molding machine, with excellent energy-saving effect, can save 20-80%.

- Adopting new heating technology, such as electromagnetic induction heating, infrared heating, etc., can achieve 20-70% of heating energy saving.

- Adopt effective insulation measures for heating and cooling systems to reduce heat and cold loss.

- Maintain good lubrication of the transmission parts of the equipment to reduce the increase in energy consumption caused by increased friction or unstable operation of the equipment.

- Select low compression hydraulic oil to reduce the waste of energy for hydraulic system work.

- Adopt parallel action, multi-cavity injection, multi-component injection molding, and other processing technologies that can significantly save energy.

- the traditional mechanical hydraulic injection molding machine also has a variety of energy-saving drive systems, instead of the traditional quantitative pump mechanical hydraulic injection molding machine energy-saving effect is significant.

- Regular maintenance of heating and cooling pipes to ensure that the internal pipeline is free of impurities, scale blockage, and other phenomena to achieve the designed heating and cooling efficiency.

- Ensure that the injection molding machine is in good working condition. Unstable processing may lead to defective products and increase energy consumption.

- Ensure that the equipment used is suitable for the products processed, such as PVC processing often requires the use of special screws.

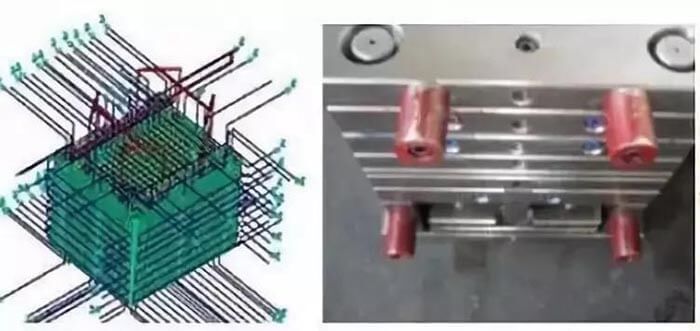

III. How to reduce the cost of injection molding processing by the injection molds?

Mold structure and mold condition often have a significant impact on the injection molding cycle and processing energy consumption.

- Reasonable mold design, including runner design, gate form, number of cavities, heating and cooling water channels, etc., can help reduce energy consumption.

- The use of hot runner mold can not only save materials and reduce the energy consumption of material recycling but also the molding process itself has a significant energy-saving effect.

- Profiling fast cooling and heating molds can significantly reduce processing energy consumption and achieve better surface quality.

- Ensure the balanced filling of each cavity, help shorten the molding cycle, ensure the uniformity of product quality, and have excellent energy-saving effects.

- Adopting CAE-aided design technology for mold design, mold flow analysis, and simulation can reduce the energy consumption of mold debugging and multiple mold repairs.

- Under the premise of guaranteeing the product quality, using a lower clamping force for molding can help prolong the mold life, facilitate the mold to be filled quickly and help save energy.

- Do a good job of mold maintenance to ensure effective heating and cooling water channel conditions.

IV. How to reduce the cost of injection molding processing by peripheral equipment?

- Choose the auxiliary equipment with the suitable capacity to meet the work requirements and not too much affluence.

- Do a good job of equipment maintenance to ensure that the equipment is in normal working condition. Auxiliary equipment that does not work properly will cause unstable production or even poor-quality parts, resulting in increased energy consumption.

- Optimize the work and operation sequence of the main machine and peripheral equipment.

- Optimize the mutual position of peripheral equipment and production equipment and make peripheral equipment as close to the main machine as possible without affecting the operating conditions.

- Many auxiliary equipment manufacturers provide on-demand energy supply systems, which can achieve significant energy savings.

- Use quick mold change equipment to reduce the waiting time required to switch products in production.

V. How to reduce the cost of injection molding processing by the materials?

Different materials consume different amounts of energy to process, and poor management of materials or improper management of recycled materials can cause increased energy consumption in production.

- Under the premise of meeting the performance of the products, materials with lower processing energy consumption should be selected as a priority.

- Under the condition of meeting the use performance and cost optimization, priority should be given to high flowability materials.

- Note that different suppliers of materials may have different process conditions.

- The material drying treatment, the best with the drying with the use, to avoid drying the material back to moisture waste energy.

- Do a good job of material preservation, to prevent materials mixed with impurities or foreign objects, ultimately causing bad products.

- Some products are allowed to add certain recycled materials but should pay attention to the preservation of recycled materials and cleanliness, to avoid the unclean materials produced by the bad parts.

VI. How to reduce the cost of injection molding processing by processing technology?

- Under the premise of meeting the performance of products, use the shortest molding cycle.

- If there are no special factors, use the processing technology recommended by the supplier for processing as far as possible.

- For specific products and molds, save all stable equipment and process parameters to shorten the time of machine adjustment for the next production change.

- Optimize the process by using lower clamping force, shorter cooling time, and holding time.

VII. How to reduce the cost of injection molding processing by adopting new technology?

- Adopt auxiliary molding technology, such as gas-assisted, liquid-assisted, steam-assisted, micro-foam injection molding technology, etc.

- Adopt a unitized molding scheme to reduce intermediate links.

- Adopt new technologies such as in-mold welding, in-mold painting, in-mold assembly, in-mold decoration, etc.

- Adopt new low-pressure molding technology to shorten the molding cycle and reduce the melt temperature at the same time.

- Adopt an energy regeneration system.

VIII. How to reduce the cost of injection molding processing by production management?

- Producing high-quality products at one time and reducing the defective rate is the biggest energy saving.

- The maintenance of the whole production system is closely related to energy consumption. This involves not only the main machine but also the peripheral and factory equipment. For example, if the workshop crane fails to change the mold, manpower is needed to change the mold, which will inevitably prolong the waiting time of the equipment and cause an increase in the energy consumption of the equipment.

- Equipped with a workshop energy consumption monitoring system, it is easy for enterprises to implement energy analysis and improvement with purpose.

- When the equipment is shut down for maintenance, not only check the maintenance content and items of the equipment itself, but also pay attention to the condition of the equipment and other system connections, and whether the working performance is reliable.

- Compare with the industry benchmark regularly to see if there is room for further improvement.

- Establish reliable contracts and cooperative relationships with suppliers, which are beneficial to the energy-saving management of enterprises.

Besides the 8 Ways to Reduce the Cost of Injection Molding Processing article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept