Description

What is DIN 25201 Double Stack Self-locking Washers?

DIN 25201 standard Dual Stacked Self-locking Washer Meaning:

DIN 25201 Dual Stacked Self-locking Washers also known as Double-sided Tooth safe Butterfly Lock washers, Double Fold lock washers, DIN25201 lock washers, and wedge lock washers. etc.

DIN 25201 Double Stack Self-locking Washers Wedge Lock washers Specifications:

The DIN 25201 Dual Stacked Self-locking Washers’ size range from 3-100 (1/4″-4′) from China Lock washers supplier DGMF Mold Clamps Co., Ltd.

DGMF Mold Clamps Co., Ltd is the mold clamps Manufacturer in China, also provides injection mold components, die press components, machine tools, and fasteners for your best choice. Contact us for more details.

What are the Wedge Lock washers composed of?

The anti-loosening lock washer wedge lock washer is composed of two washers of uniform specifications, each with a radial convex surface on the outside and a helical tooth surface on the inside.

The traditional washer is a single piece of the washer that works independently, and this washer mainly relies on friction to achieve the anti-loosening effect.

The anti-loosening wedge lock washer is composed of two identical washers, each with a radial convex surface on the outside and a helical tooth surface on the inside.

Its unique embedded structure changes the way that traditional washers achieve anti-looseness mainly through friction, but adopts the most advanced anti-loose technology in the world, and uses the tension between two washers to achieve the dual effects of anti-loose and tightening.

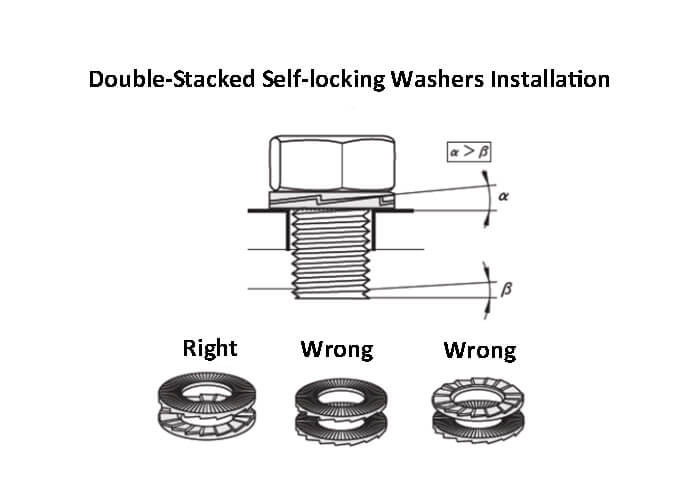

The inclination angle α of the unique washer cam teeth is greater than the inclination angle β of the bolt thread. When assembling, the inner side helical tooth surface is opposite, and the friction coefficient of the outer knurled tooth surface of the washer is larger than that of the cam tooth surface, and it is in engagement with the contact surfaces at both ends.

When the connecting piece is vibrated and the bolt tends to loosen, only the relative displacement between the helical teeth on the inner side of the two washers is allowed to generate lifting tension. The unique tooth system uses tension to produce a high resistance at the fastened joints to withstand the vibration force, so as to achieve a 100% anti-loosening effect.

How do install Double Stack Self-locking Washers?

The dual-stack self-locking washer has the characteristics of a simple installation.

- Just place the slanted tooth surfaces on the inner sides of the two washers between the nut and the connecting material;

- After the nut is tightened, the radial convex surface on the outer side of the double-stacked self-locking washer is in the occlusal state with the contact surfaces at both ends, and the slope angle of the helical tooth surface on the inner side of the washer is greater than the thread angle of the bolt;

- When the bolt is elongated due to mechanical vibration, the nut will rotate and loosen accordingly. Because the friction force of the outer radial convex surface of the self-lock washer is greater than the friction force between the inner helical tooth surfaces.

In this state, only the relative displacement between the inner helical tooth surfaces is allowed, and then a certain lifting tension is generated;

- When the bolt shrinks, the oblique tooth surface of the washer will return the nut to its original position. So as to achieve a 100% anti-loosening and tightening effect;

- The self-locking washer is suitable for a relatively flat and smooth surface;

- If the connecting material is a non-metallic material, a metal plate can be fixed on the connecting material so that the dual self-locking washer can be used;

- There is no need to use a torque wrench when installing the dual-stack self-locking washer;

- Pneumatic tools can be used when installing or removing the double-stack self-locking washer.

Assembly environment of the Double Stack Self-locking Washers/wedge lock washers

Due to the different installation environments, the requirements for the material of the gasket are also different.

There are two types of combination lock washers, one is 65Mn carbon steel plated with Dacromet, the surface is silver-gray, the price is relatively affordable, the anti-rust function is relatively low, the use cost is relatively low, and the locking effect is very good.

It is the main choice of bolt lock anti-loosening washers for general customers.

The other is a lock washer made of SUS304 stainless steel. It is expensive and costly to use and is mainly used for components that require very high anti-loose and anti-rust requirements.

Advantages of double-stack self-locking washers

- Ensure that the clamping force of the connector is still maintained under strong vibration, which is better than fasteners that rely on friction from the lock;

- Prevent bolt loosening caused by vibration, and no longer have related problems caused by loose fasteners;

- No special installation work is required, easy to install and disassemble;

- The temperature change will not make the connection piece lose;

- Has durability;

- Can be reused.

Wedge Lock Washer Detection Test

One of the methods to detect the reliability of the bolt connection in vibration is the connection vibration test. The pre-tightening force (bolt tension) is measured by a load cell. At the same time, the bolts vibrate radially.

Double-stack self-locking washer features

The highest safety performance;

Prevent loosening due to vibration and dynamic load;

Easy to install and disassemble;

The locking effect is not affected by lubrication

No matter whether the pre-tightening force is high or low, it has a good locking effect

Can control the level of pre-tightening force;

Have the same temperature characteristics as standard bolts/nuts;

Reusable.

DIN 25201 Double Stack Self-locking Washers applications

The excellent quality performance of Double Stack Self-locking Washers / DIN25201 wedge lock washers is widely used in metallurgy, the defense industry, rail transit, high-speed rail projects, machinery manufacturing, electric power, new energy, petrochemicals, auto parts, shipbuilding industry, aerospace, offshore mining equipment, mining, and construction Machinery.

Special for equipment manufacturing equipment and other industries.

Double Stack Self-locking Washers Products

Wedge lock washer

WEDGE LOCK WASHER DIN-25201 INCONEL-718;

Reviews

There are no reviews yet.