Description

What are Air Poppet Valves Air Poppets?

Air Poppets are air poppet valves used for injection molding to remedy the vacuum problem often encountered during the molding of deep-draw or thin-walled parts.

Basic characteristics of the air poppets

Air poppet is also known as air valve, air poppet valve, and pneumatic ejector pin.

In a deep airtight vacuum state, it is easier to eject with an air poppet than an ejector pin; when the product has a large surface area and is not easy to fall off, the force of the plastic part ejected by the air poppet valve is uniform and the effect is better.

The air valve cap has high precision, simple installation, no space, and great function. It is the best product for improving the ejector device at present.

The principle of air poppets

The principle is to use the air valve to control and use the principle of air diffusion to make the product fall off instantly, achieving the effect of automation. The material of the air valve top is made of stainless steel and does not rust.

The application of the air poppets eliminates the trouble in the design and production of the mold in the ejector pin, and at the same time can resolve the failure in the injection, which is a new breakthrough in the mold manufacturing industry.

Types of air poppets

The minimum diameter of the air poppet can generally be 5mm, the maximum diameter can be 30mm, and the maximum height of the gas cap can be 50mm.

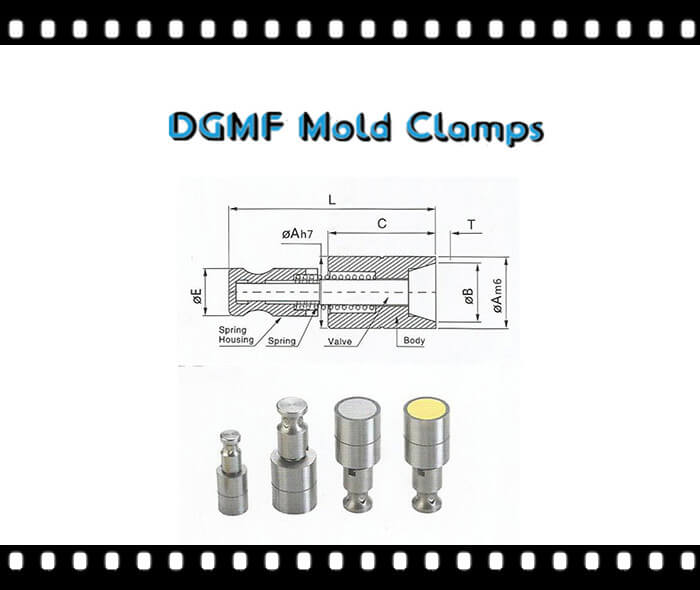

The air valve is generally composed of four parts: the shell, the ejector rod, the spring, and the elastic cylindrical pin. Domestic molds are generally used There are more common air poppets. DME air poppets, also known as VA (air valves), are more commonly used for export molds, followed by CUMSA air poppets, and HASCO air poppets are relatively rare.

If you use the international standard air poppet valve, the price is still very expensive. The above-mentioned international standard molds can basically be produced in China, and the quality is relatively reliable and stable. This kind of technology has been mastered.

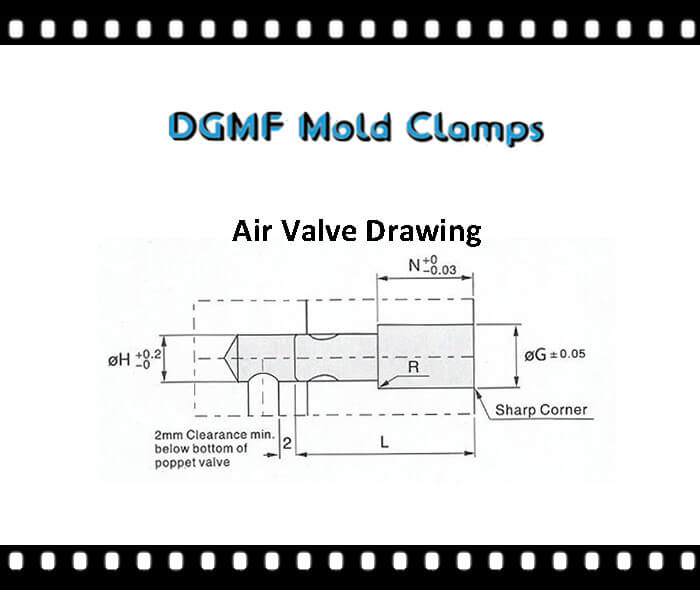

Mold air poppet valve structure

Type introduction of air poppet valve generally the smallest diameter of the air valve can be 5mm, the maximum diameter can be 30mm, and the maximum height of the gas cap can be 50mm.

The mold air valve is generally composed of four parts: shell, ejector rod, spring, and elastic cylindrical pin.

The exhaust gas will smoothly discharge all the gas in the injection mold out of mold. When the exhaust gas is not good, the gas in the cavity will be compressed to generate a large back pressure, thereby preventing the plastic melt from filling normally and quickly, and preventing the gas from compressing the chamber.

The heat generated can cause the plastic to burn. When the filling speed is fast, the temperature is high, the material viscosity is low, the injection pressure is high, and the thickness of the injection molded part is too large, the gas will penetrate into the plastic part under a certain degree of compression, causing defects such as porosity. The structure is loose.

The air tip should be used when the plastic part has no wall penetration. The ejection force of the plastic part is uniform, which solves many problems of ejecting plastic parts with other ejection structures, shortens the mold manufacturing cycle, saves mold materials, and reduces costs.

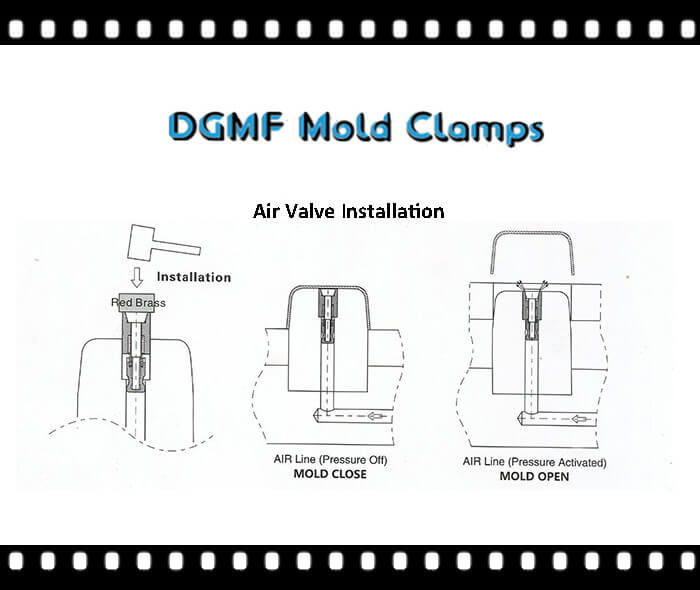

How to install the air poppet valves

Process the airway according to the size of <diameter, and press in with a softer metal or wooden hammer.

Air Poppet Valves Air Poppets Styles

40CR Air Poppet Valve Advantage:

High precision

Easy installation

Does not take up space

Hardness 44-48HRC

Great function

| 40CR Air Poppet Valve Specifications | ||

| DGMF-MOLD-CLAMP-AJV-40CR-0512 | 40CR Material Air Poppet Valve | M5X12 |

| DGMF-MOLD-CLAMP-AJV-40CR-0612 | 40CR Material Air Poppet Valve | M6X12 |

| DGMF-MOLD-CLAMP-AJV-40CR-0815 | 40CR Material Air Poppet Valve | M8X15 |

| DGMF-MOLD-CLAMP-AJV-40CR-1020 | 40CR Material Air Poppet Valve | M10X20 |

| DGMF-MOLD-CLAMP-AJV-40CR-1225 | 40CR Material Air Poppet Valve | M12X25 |

| DGMF-MOLD-CLAMP-AJV-40CR-1430 | 40CR Material Air Poppet Valve | M14X30 |

| DGMF-MOLD-CLAMP-AJV-40CR-1630 | 40CR Material Air Poppet Valve | M16X30 |

| DGMF-MOLD-CLAMP-AJV-40CR-1835 | 40CR Material Air Poppet Valve | M18X35 |

| DGMF-MOLD-CLAMP-AJV-40CR-2030 | 40CR Material Air Poppet Valve | M20X30 |

| DGMF-MOLD-CLAMP-AJV-40CR-2035 | 40CR Material Air Poppet Valve | M20X35 |

| DGMF-MOLD-CLAMP-AJV-40CR-2545 | 40CR Material Air Poppet Valve | M25X45 |

| DGMF-MOLD-CLAMP-AJV-40CR-3045 | 40CR Material Air Poppet Valve | M30X45 |

DME Standard Air Poppet Valves

DME Standard Air Poppet Product features:

Suitable for DME Standard

Stainless Steel 420 Material

6 Specifications Available

48-55 HRC Hardness

DME Standard Air Poppet Valve Specifications | ||

| DGMF-MOLD-CLAMP-VA-D0824 | SUS420 Material Air Poppet Valve | M8X24 |

| DGMF-MOLD-CLAMP-VA-D1024 | SUS420 Material Air Poppet Valve | M10X24 |

| DGMF-MOLD-CLAMP-VA-D1234 | SUS420 Material Air Poppet Valve | M12X34 |

| DGMF-MOLD-CLAMP-VA-D1638 | SUS420 Material Air Poppet Valve | M16X38 |

| DGMF-MOLD-CLAMP-VA-D1846 | SUS420 Material Air Poppet Valve | M18X46 |

| DGMF-MOLD-CLAMP-VA-D2050 | SUS420 Material Air Poppet Valve | M20X50 |

Stainless Steel Air Poppet Valves

The air poppets are designed to break the vacuum created during injection molding. They are built to provide long life using all stainless steel materials and are heat-treated to 48-56 HRC.

Stainless Steel SUS420 Air Poppet Valve Product Features:

In a deep and airtight vacuum state, it is easier to use the air valve to eject than the ejector pin. When the product has a large surface area and is not easy to fall off, the air valve is used. The force of the ejected plastic parts is uniform and the effect is better.

Stainless Steel SUS420 Air Poppet Valve Specifications | ||

| DGMF-MOLD-CLAMP-VA-SUS420-0512 | SUS420 Material Air Poppet Valve | M5X12 |

| DGMF-MOLD-CLAMP-VA-SUS420-0612 | SUS420 Material Air Poppet Valve | M6X12 |

| DGMF-MOLD-CLAMP-VA-SUS420-0815 | SUS420 Material Air Poppet Valve | M8X15 |

| DGMF-MOLD-CLAMP-VA-SUS420-1020 | SUS420 Material Air Poppet Valve | M10X20 |

| DGMF-MOLD-CLAMP-VA-SUS420-1225 | SUS420 Material Air Poppet Valve | M12X25 |

| DGMF-MOLD-CLAMP-VA-SUS420-1430 | SUS420 Material Air Poppet Valve | M14X30 |

| DGMF-MOLD-CLAMP-VA-SUS420-1630 | SUS420 Material Air Poppet Valve | M16X30 |

| DGMF-MOLD-CLAMP-VA-SUS420-1835 | SUS420 Material Air Poppet Valve | M18X35 |

| DGMF-MOLD-CLAMP-VA-SUS420-2030 | SUS420 Material Air Poppet Valve | M20X30 |

| DGMF-MOLD-CLAMP-VA-SUS420-2035 | SUS420 Material Air Poppet Valve | M20X35 |

| DGMF-MOLD-CLAMP-VA-SUS420-2545 | SUS420 Material Air Poppet Valve | M25X45 |

| DGMF-MOLD-CLAMP-VA-SUS420-3045 | SUS420 Material Air Poppet Valve | M30X45 |

CUMSA Standard VA Poppet Valves

CUMSA Standard Air Poppet Valves Specifications | ||

| DGMF-MOLD-CLAMP-VA-050412 | Air Poppet Valve Ø5 | M4X12 |

| DGMF-MOLD-CLAMP-VA-065212 | Air Poppet Valve Ø6 | M5X12 |

| DGMF-MOLD-CLAMP-VA-086512 | Air Poppet Valve Ø8 | M6X12 |

| DGMF-MOLD-CLAMP-VA-100812 | Air Poppet Valve Ø10 | M8X12 |

| DGMF-MOLD-CLAMP-VA-121012 | Air Poppet Valve Ø12 | M10X12 |

| DGMF-MOLD-CLAMP-VA-161320 | Air Poppet Valve Ø16 | M16X20 |

| DGMF-MOLD-CLAMP-VA-201720 | Air Poppet Valve Ø20 | M20X20 |

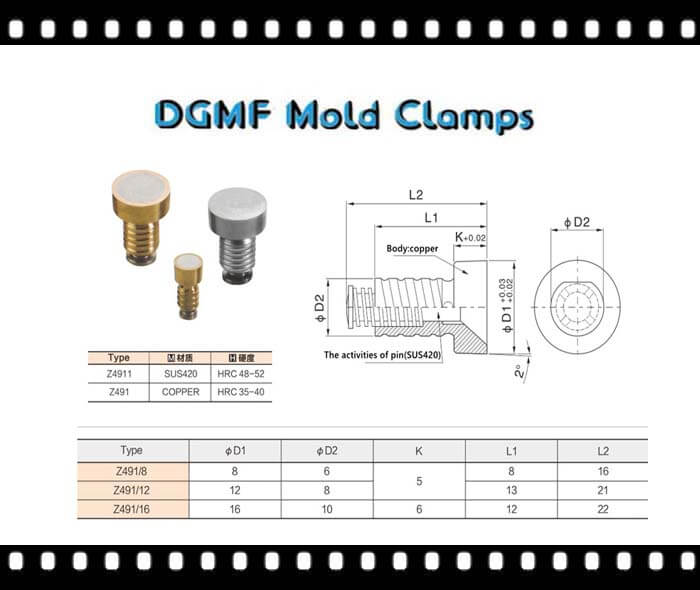

The Z491 air poppet valve is made of brass, and the Z4911 air poppet valve is made of stainless steel. Thread design, easy to install and assemble, and under high pressure will not fall out of the mold.

| Z491/Z4911 Air Poppet Valve Specifications | ||

| DGMF-MOLD-CLAMP-VA-Z491/8/6 | Brass Material Air Poppet Valve | M6X8 |

| DGMF-MOLD-CLAMP-VA-Z491/12/8 | Brass Material Air Poppet Valve | M8X12 |

| DGMF-MOLD-CLAMP-VA-Z491/16/10 | Brass Material Air Poppet Valve | M10X16 |

| DGMF-MOLD-CLAMP-VA-Z4911/8/6 | SUS420 Material Air Poppet Valve | M6X8 |

| DGMF-MOLD-CLAMP-VA-Z4911/12/8 | SUS420 Material Air Poppet Valve | M8X12 |

| DGMF-MOLD-CLAMP-VA-Z4911/16/10 | SUS420 Material Air Poppet Valve | M10X16 |

DGMF Mold Clamps Co., Ltd is the mold clamps Manufacturer in China, also provides injection mold components, die press components, machine tools, and fasteners for your best choice. Contact us for more details.

Reviews

There are no reviews yet.