What is table tennis?

Table tennis, also known as ping-pong and whiff-whaff, is a sport in which two or four players hit a lightweight ball, also known as the ping-pong ball, back and forth across a table using small rackets. The game takes place on a hard table divided by a net.

How is table tennis made? It turned out to be glued together with two plastic sheets.

As a ball sport, table tennis also has strict requirements for the ball. The table tennis ball is spherical, with a diameter of 40 mm, a weight of 2.53~2.70 grams, and a white or orange color.

How table tennis is manufactured?

Configuration material

The material for table tennis was originally made of synthetic fiber plastic (nitrocellulose plastic), also called celluloid. From July 1, 2014, a new plastic ball made of the high-molecular polymer was used as a raw material.

In the material factory, the raw materials are made into sheets with a diameter of 44 mm and a thickness of 0.8 mm.

Prepare a solution according to 40% alcohol and 60% water, put the plastic sheet into it, and let it soften during the soaking process so that it can be uniformly formed.

The soaked sheet should be rinsed with clean water to remove the solution on the surface, and the moisture on the surface should be dried.

Forming

First, a metal mold is used to make the plastic sheet into a hemispherical shape, and the sheet is fixed on the mold, and the sheet is immersed in hot water of more than 90 degrees while pressing.

After the sheet is made into a hemispherical shape, it needs to be quickly cooled with water. After being removed from the mold, one hemisphere of the ping-pong ball is completed.

After the sheet is made into a hemispherical shape, it needs to be quickly cooled with water. After being removed from the mold, one hemisphere of the ping-pong ball is completed.

All the burrs on the edges of the hemisphere should be cut clean by the machine.

Detection classification

To measure the thickness of each hemisphere, classify the hemispheres of different thicknesses, and the thickness difference between each group is only 0.01 mm.

Glue

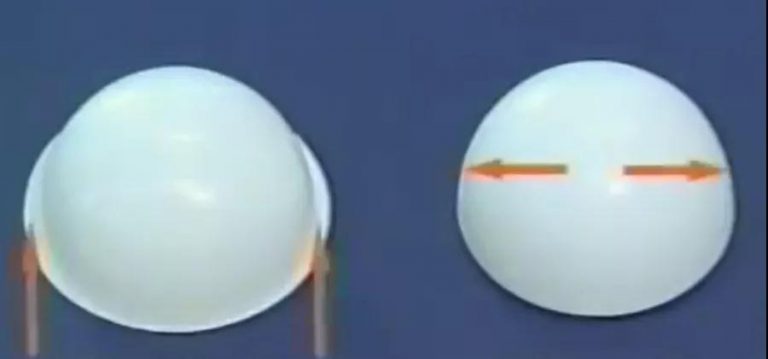

After screening, each group of hemispheres with similar thicknesses are glued together, and one hemisphere is placed in the mold and heated to make the edge shrink and shrink.

Cover the reduced hemisphere with another hemisphere, apply glue through the machine, and the glue will flow to the hemisphere interface along the gap.

Squeezing hard on the hemisphere by the machine will completely bond the two hemispheres together to form a round ping pong ball.

Thermoforming

Put the ping pong ball into a metal mold. There will be many small holes on the surface of the mold. Put it in a 380-degree oven to expand the air in the ball, so that the joints are tighter and smoother.

In order to clean the glue on the surface of the table tennis ball, make the joints smoother, and reach the required weight, the table tennis ball is placed in a polishing machine for polishing.

Detect

Detect whether the seams are intact and uniform by light, and perform weighing and rotation tests on the table tennis balls, and perform grading. The high-quality ones are used for competitions, and the low-quality ones are used for training.

Finally, the brand and grade are printed on the graded table tennis balls, so that the table tennis balls are made.

Today, table tennis is still one of the favorite sports of the Chinese people. It has become a ping-pong spirit of winning glory for the country, working hard, and constantly innovating, which continues to inspire countless people.

You may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept

18 FAQ Of Injection Molding Machine Mold Clamping