What is the Understanding of the Injection Molding Process?

This article is from a senior process engineer, who shares some understanding of the injection molding process. Mold temperature of the injection molding process The mold temperature affects the injection molding process cycle and injection molding process quality. In practice, the mold temperature is set from the lowest appropriate mold temperature for the material used […]

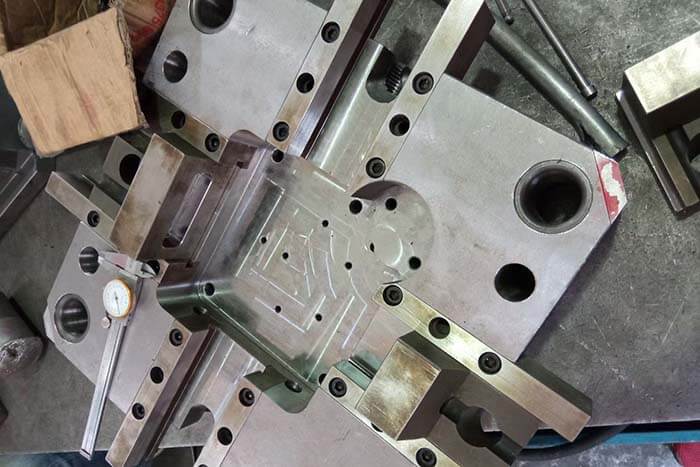

10 Problems and Solutions in Mold Trial

This article is talking about the ten problems and solutions in injection mold trials. Here we go! Common problem in mold trial 1: Main sprue sticking to the injection mold Method and order to solve the problem. To polish the main sprue Nozzle and mold center coincide Lower the mold temperature Shorten the injection molding […]

What is PBT Injection Molding Condition?

After the read, you will know about what are the process conditions of PBT injection molding. With the rapid development of the plastics industry, new varieties of modified plastics are emerging, and polyethylene terephthalate (abbreviated as PBT) is an engineering material with excellent performance. What is PBT material? PBT is a milky white translucent to […]

What are the Effects of Injection Temperature and Speed on Product Shrinkage?

What is shrinkage in plastic molding? Shrinkage is the contraction of a plastic molded component as it begins to cool after the injection process. All plastics shrink as they cool from viscous liquids to solids and every type of plastic shrinks in a slightly different way. The effect of injection temperature and speed on product […]

9 FAQs on Injection Molding Process Optimization

Today, we talk about the list of questions and answers relating to the injection molding process optimization. If you had other injection molding process optimization methods, please share with us, thank you. Injection Molding Process Optimization FAQ 1 Question: Briefly describe the working condition of check valve during plasticization, injection, and pressure-holding process; Answer: Plasticizing: […]

88 Common Mold Design Knowledge

Today, we talk about engineering is concerning 88 common mold design knowledge points. Mold design knowledge 1. What are the commonly used plastic engineering materials and shrinkage rates? ABS: 0.5% (super unbreakable glue) PC: 0.5% (bulletproof glass glue) PMMa: 0.5%: (plexiglass) PE: 2% polyethylene PS: 0.5%(polyphenylene vinyl) PP: 2% (Pepto-Bismol) PA: 2% (nylon) PVC: 2%(polyvinyl […]

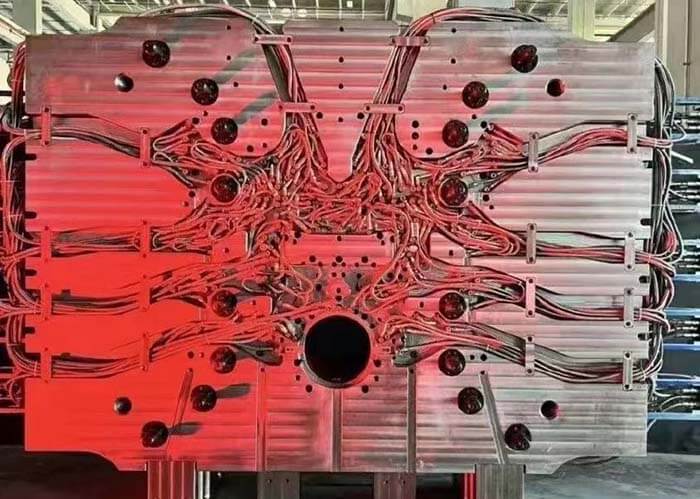

5 Ways How Hot Runner Molding Increases Efficiency

Why is hot runner molding so popular? Injection molding is the plastics manufacturing process of choice for major plastics-consuming industries, such as automotive and medical. In the United States, there are nearly 16,000 plastic molding and plastics manufacturing facilities in all 50 states. In China, the export of injection molds ranks among the top in […]

16 Knowledge of Injection Molding Basics

After the read this 16 Knowledge collection of injection molding basics, you will learn the 16 listed knowledge collection of injection molding basics. Injection molding basics 1. Pre-injection molding action selection According to the pre-molding charging before and after the injection seat back, that is, whether the nozzle leaves the mold, the injection molding machine […]

What is Flow Mark Injection Molding?

What is the flow mark injection molding? How does the flow mark injection molding occur? How to solve the flow mark troubleshooting in injection moulding? Flow mark injection molding in plastic 1. Poor flow Flow Length to Thickness Ratio large cavity must be filled with easy-to-flow plastic. If the flow of plastic is not good […]

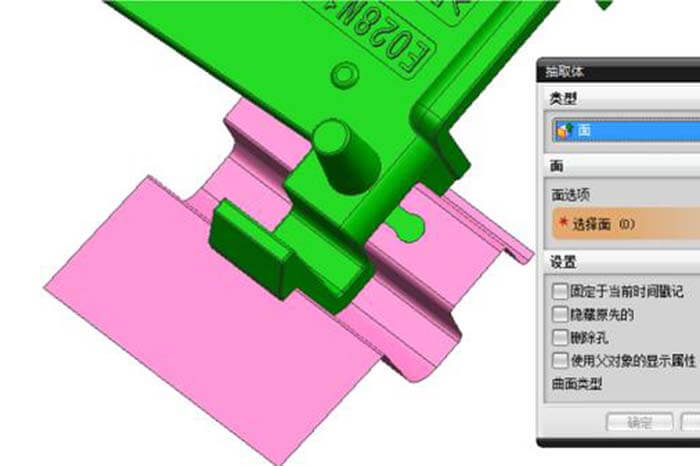

The 10 Principles of Mold Design Parting

Do you know the principles of mold design parting? Through the communication with mold designers, we summarized the 10 main guidelines of the principles of mold design parting. Although these guidelines in mold parting design may not all meet, or even conflict, they do put forward from different aspects of the mold design parting surface […]