Bolts

-

Three In One Multi-functional Combination Eyebolt For Lifting

Read more -

T Slot Bolts

Read more -

T Bolts For Milling Machine

Read more -

T Bolts And Nuts

Read more -

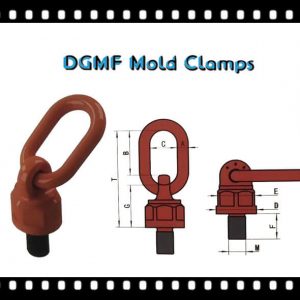

Swivel Eye Bolt For Lifting

Read more -

Stainless Steel Knurled Phillips Thumbscrews

Read more -

Stainless Steel Knurled Flat Head Thumbscrew

Read more -

Stainless Steel Hexagonal Stud Bolts With Right Hand Left Hand Threaded

Read more -

Stainless Steel 304 Left Hand Threaded Rod

Read more -

Self-Clinching Fasteners Spring-loaded Captive Panel Screws

Read more -

Self-clinching Blind Fasteners Blind Press Nuts

Read more -

Sefl-clinching Fasteners Captive Panel Screws

Read more -

Scrap Breakers for Cam Pierce Dies CPSBR Srew Plug

Read more -

Saw Blade Bolt Left-hand Screw

Read more -

Mold Clamping Stud With Spanner

Read more -

Lifting Eyebolts Screw Type Lifting Points

Read more -

Knurled Head Thumb Screws With Shoulder

Read more -

Jack Nuts Petal Nuts Threaded Insert Screw Anchors

Read more -

High-Pressure Plugs Tapered Screw Plugs

Read more -

Forged and Hardened Mold Clamping Stud

Read more -

Forged and Hardened Mold Clamp Bolts

Read more -

Chicago Binding Screws Sex Bolt

Read more -

CD Weld Standoffs

Read more -

Ball Screw Set Smooth Ball Plunger Spring Plunger

Read more -

Ball Plungers Ball Nose Spring plungers

Read more -

12.9 Grade Square Head T Bolt

Read more

Bolts Supplier

DGMF Mold Clamps Co., Ltd is the bolts and nuts supplier and mould clamps manufacturer in China.

What is a Bolt?

Bolts are mechanical parts, cylindrical threaded fasteners with nuts.

A type of fastener consisting of a head and a screw (cylinder with an external thread), which needs to be matched with a nut to fasten and connect two parts through holes. This type of connection is called a bolt connection.

If the nut is unscrewed from the bolt, the two parts can be separated, so the bolt connection is a detachable connection.

Bolt Classifications

Cap screws used to be limited to full-tooth fasteners.

Hex cap screw and Hex bolt, as the name suggests, are externally threaded fasteners with a hexagonal head, designed to be rotated by a wrench.

According to the ASME B18.2.1 standard, the hexagon head screw (Hex cap screw) has a smaller head height and rod length tolerance than the general large hexagon bolt (Hex bolt), so ASME B18.2.1 hexagon screw is suitable for installation on all hexagon bolts that can be used Places, including places where large hexagon bolts are too large to be used.

A socket cap screw (also known as a hex socket cap screw) is a screw with a hexagonal inner hole on the head. It can be tightened or loosened after inserting a hexagonal ruler (hex key, Allen wrench, or Allen key) into the inner hole.

Hexagon socket screws are the most commonly used cylinder head screws, the head diameter is about 1.5 times the main diameter of the thread (1960 series), other head types include the Bottom head cap screw for beautiful surface and suitable for tapered screw holes Countersunk head cap screw (Countersunk head cap screw).

The counterbore design allows the screw head to be able to rotate without being exposed to the surface of the fixed object, so it is mostly used in places where the surface is small and the traditional wrench is inconvenient.

According to the force mode of the connection, it is divided into ordinary and reamed holes.

According to the head shape, there are a hexagonal head, round head, square head, countersunk head, and so on.

The hexagonal head is the most commonly used. The countersunk head is generally used where the connection is required.

The English name of the riding bolt is U-bolt. It is a non-standard part. The shape is U-shaped, so it is also called U-bolt. Both ends have threads that can be combined with nuts.

They are mainly used to fix tubular objects such as water pipes or sheet objects such as car plates. reed. According to the thread length, it is divided into full thread and non-full thread.

According to the thread type, it is divided into two types: coarse thread and fine thread. The coarse thread type is not displayed in the bolt mark.

Bolts are divided into eight grades: 3.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, and 12.9 according to their performance grades.

Among them, bolts of grade 8.8 and above (including grade 8.8) are made of low-carbon alloy steel or medium carbon steel and are heat-treated (quenched + tempered). They are generally called high-strength bolts, and those below 8.8 (not including 8.8) are generally called ordinary bolts.

Ordinary bolts can be divided into three grades of A, B, and C according to the manufacturing accuracy. Grades A and B are refined bolts, and grade C is coarse bolts. For connecting bolts for steel structures, unless otherwise specified, they are generally ordinary crude grade C bolts.

The bolt performance grade label consists of two parts of numbers, which respectively indicate the nominal tensile strength value and the yield ratio of the bolt material.

Stainless steel bolts are divided into A1-50, A1-70, A1-80, A2-50, A2-70, A2-80, A3-50, A3-70, A3-80, A4-50, A4-70, A4-80, A5-50, A5-70, A5-80, C1-50, C1-70, C1-110, C4-50, C4-70, C3-80, F1-45, F1- 60.

The first letter and number represent the group of stainless steel, and the second and third numbers represent 1/10 of the tensile strength.

The processing methods of different levels are different, and the corresponding processing methods are usually as follows:

① The bolts of grade A and grade B bolts are processed by lathes, with a smooth surface and precise size. The material performance grade is 8.8, the production and installation are complicated, the price is high, and it is rarely used;

②Class C bolts are made of unprocessed round steel, and the size is not accurate enough. The material performance level is 4.6 or 4.8. Large deformation during shear connection, but convenient installation and low production cost, it is mostly used for tensile connection or temporary fixation during installation.

Bolt Applications

Bolts are tools that use the physics and mathematics of the oblique circular rotation and friction of objects to gradually tighten objects and parts.

Bolts are indispensable in daily life and industrial production. Bolts are also called industrial rice. It can be seen that the bolts are widely used.

The application range of bolts includes electronic products, mechanical products, digital products, electrical equipment, electromechanical mechanical products. Bolts are also useful in ships, vehicles, water conservancy projects, and even chemical experiments.

Miniature bolts used in DVDs, cameras, glasses, watches, electronics, etc.; general bolts used in televisions, electrical products, musical instruments, furniture, etc.;

As for engineering, construction, and bridges, large bolts and nuts are used; transportation equipment, airplanes, trams, automobiles, etc. are used together. Bolts have important tasks in the industry. As long as the industry exists on the earth, the function of bolts will always be important.

Bolt Shapes

Generally, the countersunk head is used where the surface after the connection is required to be smooth without protrusions because the countersunk head can be screwed into the part.

The round head can also be screwed into the part. The tightening force of the square head can be larger, but the size is large. In addition, in order to meet the needs of locking after installation, there are holes on the head and holes on the rod. These holes can prevent the bolt from loosening when it is vibrated.

Some bolts are not threaded smooth rods to be thin, called thin waist bolts. This kind of bolt is conducive to the connection under variable force. There are special high-strength bolts on the steel structure, the head will be larger and the size will also change.

In addition, there are special uses: T-slot bolts, the most used on machine tool fixtures, special shapes, and both sides of the head should be cut off.

Anchor bolts are used to connect and fix the machine and the ground. There are many shapes.

U-shaped bolts, as mentioned above. and many more. There are also special studs for welding. One end has a thread and the other is not. It can be welded to the part and the nut is directly screwed on the other side.

Bolt Force method

Ordinary and with reamed holes. The ordinary main load-bearing axial force can also bear a less demanding lateral force. The bolts used for reaming holes should be matched with the size of the holes and used when subjected to lateral forces.

Bolt inspection

There are two types of bolt detection: manual and machine. Manual is the most primitive and most commonly used consistent detection method. In order to minimize the outflow of defective products, the general production company personnel inspect the packaged or shipped products by visual inspection to eliminate defective products (defects include tooth injuries, mixing, rust, etc.).

The other method is automatic machine inspection, mainly magnetic particle inspection. Magnetic particle inspection uses the interaction between the leakage magnetic field at the bolt defect and the magnetic powder to deal with the difference between the magnetic permeability of the bolts (such as cracks, slag inclusions, mixing, etc.) and the magnetic permeability of steel. These materials are discontinuous after magnetization.

The magnetic field will be turbulent, forming part of the magnetic flux leakage, and the leakage magnetic field will be generated on the surface of the workpiece, thereby attracting the magnetic powder to accumulate the magnetic powder at the defect site to become magnetic marks. Under proper lighting conditions, the defect position and shape will appear. The accumulation of magnetic powder is observed and explained, and the purpose of rejecting defective products has been achieved.

What is Screw?

A screw is a tool that uses the physics and mathematics of the oblique rotation of the object and the friction force to gradually tighten the objects and parts.

The function of the screw is mainly to connect the two workpieces together and act as a fastening.

The screw is a general term for fasteners, a daily oral language.

Screws are indispensable industrial necessities in daily life: such as extremely small screws used in cameras, glasses, watches, electronics, etc.;

General screws for televisions, electrical products, musical instruments, furniture, etc.;

As for engineering, construction, and bridges, large screws and nuts are used;

Transportation equipment, airplanes, trams, cars, etc. are used for both small and large screws.

Screws have important tasks in the industry. As long as there is an industry on the earth, the function of screws will always be important.

The screw is a common invention in people’s production and life for thousands of years. According to the application field, it is the first invention of mankind.

Basic screw meaning

In fact, the screw is a generic term, and screws and bolts are different from each other. Screws are generally called wood screws; they are those with a pointed tip and have a larger pitch. They are generally used to fasten wooden and plastic parts.

The bolt is a machine screw, which has a flat front end, with a small pitch and uniform pitch, and is generally used to fasten metal and machine parts.

Screw classification

The main categories include ordinary screws, machine screws, self-tapping screws, and expansion screws.

Machine screws are generally screws with a diameter of smaller than 14 inches (4#~12#), usually full-threaded and rotated by a screwdriver, such as slotted, cross, or hexagon socket.

Wood screws and machine screws; but according to different uses, they can be divided into many categories; machine screws can be divided into longitudinal fastening screws and horizontal expansion screws;

According to threads, they can also be divided into:

A: Triangular thread (60 degrees): combination/locking/expansion

B: Triangular thread for pipe (55 degrees): Combine/lock 3)

C: Trapezoidal thread (30 or 29 degrees): power transmission

D: Square thread (90 degrees): power transmission

Stainless steel screw

Stainless steel drop-resistant screws

Screws And Shafts For Motorcycle Or Bicycle

Screws And Shafts For Sewing Machining

Socket Set Screws

Stainless Steel Coarse Thread Screws

Stainless Steel High-Low Thread Screws

Stainless Steel Machine Screws

Stainless Steel Self Drilling Screws

Stainless Steel Self Tapping Screws

Stainless Steel Thread Cutting Screws

Stainless Steel Tri-Lobular Thread Screws

Model Description

P refers to the head type is PAN head;

A refers to pointed tail teeth;

B refers to flat tail teeth, that is, PA round head pointed steel teeth, PB round head flat teeth.

Self-tapping category:

◆Roundhead tapping screws PA

◆Roundhead and flat tail tapping screws PB

◆Roundhead cutting tail self-tapping screw PT

◆PWA with a round head and self-tapping screws

◆Roundhead with flat tail self-tapping PWB

◆Roundhead belt with medium cut tail self-tapping PWT

◆ Countersunk head tapping screws KA

◆ Countersunk head flat tail self-tapping screw KB

◆ Countersunk self-tapping screws KT

◆Half countersunk head tapping screw OA

◆Bighead tapping screw BA

◆Bighead flat tail tapping screw BB

◆Big flathead tapping screw TA

◆Big flathead and flat tail tapping screws TB

◆Large flat head self-tapping screw TT

◆Thin head tapping screw CA

◆Thin head flat tail self-tapping screw CB

◆Cup head hexagon socket self-tapping HA

◆Drywall nails/wallboard nails/fiber nails

Machine wire category:

◆Roundhead machine screw PM

◆ Roundhead with medium machine screw PWM

◆Large Flat Head Machine Screw TM

◆Counter head machine screw KM

◆Half countersunk head machine screw OM

◆Bighead machine screw BM

◆Thin head machine screw CM

◆Cup head machine screw HM

Common screw categories

Various common screws

Various common screws (20 sheets)

a. Slotted: One word (Minus)

b. Phillips: Cross (Plus)

c. Phil-Slot: One word/cross

d. Hex Socket: Hex socket

e. One Way: one way (only lock-in, not exit)

A-4: Head Code/ Head shape.

a. Flat: Flathead (after locking, the top is flush with the workpiece)

b. Oval: Salad head, O head, semi-sunk head

c. Round: Roundhead

d. Pan: round flat head

e. Truss: Big round flat head

f. Hex: Hexagon head.

Industrial screw applications

The main purpose is to make industrial products integrated and fixed. In use, it often happens that the teeth cannot be closely attached to the teeth, the screw heads are broken if the tightening is too strong, or the teeth are not locked and the conditions are not met.

These are all accuracy problems. Screws are quantity products, not hand-made artworks. In mass production, they are supplied to consumers for the purpose of achieving high precision, stable quality, and popular prices.

The accuracy of screws is usually 6g (level 2, American standard “IFI” is 2A thread), and the rough screw used in construction engineering is 8g (level 3, “IFI” is 1A thread).

Common screw types

A: Machine Screw: Machine Screw

B: Tapping Screw: Self-tapping screw (for metal and plastic)

B-1: Sheet Metal Tapping Screw. (Self-tapping screw)

B-2: Plastic Tapping Screw. (for plastic, self-tapping screw)

C: Wooden Screw: Woodworking Screw

D: Drywall Screw: Cement wall screw

E: Self Drilling Screws (Stainless Steel Drilling Screws, Composite Drilling Screws)

F: Expansion screw, a four-piece expansion screw is also known as a four-piece gecko. The grades of expansion bolts are divided into 45, 50, 60, 70, 80,

The material of expansion screws: mainly divided into austenite A1, A2, A4,

1. Stainless steel plate, metal steel plate, galvanized steel plate, engineering installation.

2. Indoor and outdoor installation of metal curtain wall, metal light partition, etc.

3. General angle steel, channel steel, iron plate, and other metal materials are combined and installed.

4. Assembling projects for automobile trunks, container boxes, shipbuilding, refrigeration, and screw machine equipment.

Screw Features:

1. Drilling and tapping, locking can be completed at one time, strong binding force.

2. Save construction time and improve work efficiency.

E-1: STAINLESS STEEL SELF DRILLING SCREWS

E-2: Bi-Metal Self Drilling Screws

Common screw materials

a.Low Carbon Steel:

Carbon steel is divided into low carbon steel, medium carbon steel, high carbon steel, and alloy steel.

b. SS-304: Stainless Steel 304, 316

c. SS-302: Stainless Steel 302

d. Aluminum 5052

d. Brasse

e. Bronze

f. UNS C11000 Copper

Bolts And Screws Types:

Hex Head Cap Screws(Hex Bolts)

Hex Head Machine Bolts

Hex Lag Bolts

Square Head Bolts

T Head Bolts

Carriage Bolts

Eye Bolts

Hex Socket Cap Screws

Set Screws

Stud Bolts

Screw Studs

Wheel Bolts

Wing Screws

Self Tapping Screws

Thread Cutting Screws

Self Drilling Screws

Drive Screws

Machine Screws

Wood Screws

Furniture Screws

Chipboard Screws

Drywall Screws

Foundation Bolts

U Bolts

Hook Bolts

Toggle Bolts

Flange Bolts

Track Bolts(Fishtail Screws)

Corten Steel Heavy Hex Bolts

T.C.bolts(Torque Control Bolt )

High Strength Bolts

Welding Studs(Shear Nails/Welding Screws)

Screws And Washers Assembled(SEMS)

Big Size Bolts

Stainless Steel Sheet Metal Screws

Stainless Steel Bolts

Brass Screws

Aluminum Screws

Alloy Steel Screws

Electronic Screws

Micro Screws

Plastic Screws

Particle Board Screws

Titanium Alloy Bolts

Ti, Zr, Mo, Nb Pare Metal Bolts Parts(Titanium, Zirconium, Molybdenum, Niobium, And Other Screws, Parts, Materials)

Thumb Screws

Double End Screws Hanger Bolt

Automotive Fasteners(vehicle/Automotive Screws, Nuts)

Aerospace Fasteners

Source Control Bolts(Aircraft Special Fasteners)

Blind Bolts(Pull Bolt)

Panel Fasteners(Panel Screws)

Elevator Bolts(Elevator Screws)

Square Set Screws

Step Bolts

One Way Lag Screws

Hose Clamp Screws

Stainless Steel Hex Socket Cap Screws

Hinge Screws

Container Screws

Bi-metal Self Drilling Screws(Composite Self-drilling Screw)

Tri lobular Thread Screws

High Low Screws

Particle Board Screws

Toilet Closet Bolts

Special Longer Screws

Building Fasteners

Stainless Steel Hex Socket Cap Screws

Special Stainless Steel Screws

Coarse Thread Screws(Wide Thread Screw)

Collated Screws

Concrete Screws

Construction Bolts(Formwork Screws)

Die-cast Wing Screws; Zinc Alloy

Heavy-duty Wheel Hub Bolts

Hex Socket Set Screws

Particle Board Screws(Screws For Composite Materials For Splints)

Plow Bolts

Screws And Shafts For Motorcycle Or Bicycle

Screws And Shafts For Sewing Machine

Socket Set Screws

Stainless Steel Coarse Thread Screws

Stainless Steel High-low Thread Screws

Stainless Steel Machine Screws

Stainless Steel Self Drilling Screws

Stainless Steel Self Tapping Screws

Stainless Steel Thread Cutting Screws

Stainless Steel Tri-lobular Thread Screws

Stainless Steel Wood Screws

Toggle Bolts

Titanium Alloy Expansion Bolts

DGMF Mold Clamps Co., Ltd manufactures the mold clamps, and supplies the injection mold components, such as Clamps, Toggle Clamps, C Clamps, Pins, Bushings, Positioning Components, Lock Mold Components, Reset Extrusion, Cavity, and Core Components, Coolings, Die Press Components, Punch And Die, Guide Components, Self-lubricating Components, Springs, Machine Tools, Gate Valves, Machine Mounts, Vises, Fasteners, Lifting, Bolts, Nuts, Washers, etc.

Contact the DGMF Mold Clamps teams for more details about the bolts & screws such as bolt specifications, bolt pricing, bolt inventory, etc.

Showing 1–16 of 26 results

-

12.9 Grade Square Head T Bolt

Read more -

Ball Plungers Ball Nose Spring plungers

Read more -

Ball Screw Set Smooth Ball Plunger Spring Plunger

Read more -

CD Weld Standoffs

Read more -

Chicago Binding Screws Sex Bolt

Read more -

Forged and Hardened Mold Clamp Bolts

Read more -

Forged and Hardened Mold Clamping Stud

Read more -

High-Pressure Plugs Tapered Screw Plugs

Read more -

Jack Nuts Petal Nuts Threaded Insert Screw Anchors

Read more -

Knurled Head Thumb Screws With Shoulder

Read more -

Lifting Eyebolts Screw Type Lifting Points

Read more -

Mold Clamping Stud With Spanner

Read more -

Saw Blade Bolt Left-hand Screw

Read more -

Scrap Breakers for Cam Pierce Dies CPSBR Srew Plug

Read more -

Sefl-clinching Fasteners Captive Panel Screws

Read more -

Self-clinching Blind Fasteners Blind Press Nuts

Read more