Self-Lubricating Components

Self-Lubricating Components Supplier

DGMF Mold Clamps Co., Ltd is the Self-Lubricating Components supplier and mould clamps manufacturer in China.

What is Solid self-lubricating material?

Solid lubricating materials refer to the use of solid powders, films, or some integral materials to reduce the friction and wear between two bearing surfaces.

In the solid lubrication process, the solid lubricating material and the surrounding medium have to physically and chemically react with the friction surface to form a solid lubricating film to reduce friction and wear.

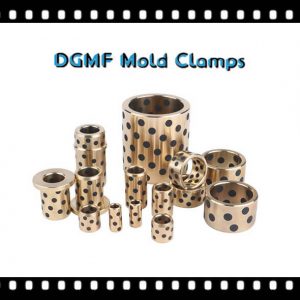

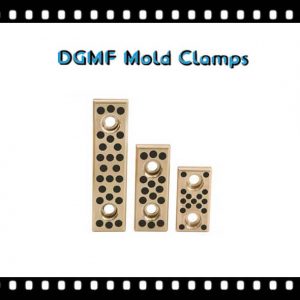

We have the Self-lubricating Guide Bushings For Injection Molding, Self-lubricating Bronze Wear Plate, etc.

Self-Lubricating Components Basic performance

1) It can adhere firmly to the friction surface and protect the surface.

The solid lubricant should have a good film-forming ability, can form a strong chemical adsorption film or physical adsorption film with the friction surface, and adhere to the surface to prevent relative movement between the surfaces Produce severe welding or mutual transfer of metals.

2) Lower shear strength.

Solid lubricants have lower shear strength so that the friction coefficient of the friction pair is small, the power loss is low, and the temperature rise is small. And its shear strength should not change in a wide temperature range so that it has a wider application field.

3) Good stability, including physical thermal stability, chemical thermal stability and aging stability, no corrosion, and other harmful effects.

Physical thermal stability means that without active substances, temperature changes will not cause phase changes or lattice changes. This kind of change will not cause a change in the shear strength, resulting in a change in the friction properties of the solid.

Chemical thermal stability means that temperature changes in various active media will not cause strong chemical reactions.

The physical and chemical thermal stability of solid lubricants is required to take into account that the performance of high temperature, ultra-low temperature, and use in chemical media will not change much, and aging stability means that solid lubricants are required to be stored for a long time without deterioration for long-term use.

In addition, it is required to be non-corrosive to bearings and related parts, non-toxic to humans and animals, and not pollute the environment.

4) Solid lubricants are required to have a high load-bearing capacity.

Because solid lubricants are often used in severe working conditions and environmental conditions such as low speed and high load, it is required to have a high load-bearing capacity and easy to cut.

Self-Lubricating Components Instructions

1) Use certain engineering plastics such as polytetrafluoroethylene, polyacetal, polyoxymethylene, polycarbonate, polyamide, polysulfone, polyimide, chlorinated polyether, polyphenylene sulfide, and polyp.

The friction coefficient of phthalate esters is low, the forming processability and chemical stability are good, the electrical insulation is excellent, the impact resistance is strong, and it can be made into integral parts.

If ring glass fiber, metal fiber, graphite fiber, These plastics are reinforced by boron fiber and have better overall performance. Gears, bearings, guide rails, cams, rolling bearing cages, etc. are used more frequently.

2) Making various covering films to apply solid lubricants to the friction interface or surface to make it a dry film with certain self-lubricating properties. This is one of the more commonly used methods.

There are many film-forming methods, and various solid lubricants can be formed by sputtering, electrophoretic deposition, plasma spraying, ion plating, electroplating, adhesive bonding, chemical generation, extrusion, dipping, rolling, and other methods.

3) The so-called composite (combined) material is used to make composite or combined materials, which refers to a material system that is used by combining or compounding two or more materials.

The physical and chemical properties and shapes of these materials are different, and they are insoluble in each other.

The ultimate goal of combination or compounding is to obtain a new material with better performance, which is generally called composite material.

4) Use as a solid lubricating powder. Add solid lubricating powder (such as MoS2) to lubricating oil or grease in an appropriate amount to increase the carrying capacity of the lubricating grease and improve the lubrication state, such as MoS2 oil, MoS2 ointment, MoS2 grease, and MoS2 water agent, etc.

Self-Lubricating Components Function and performance

1) Molybdenum disulfide

(1) Low friction characteristics.

(2) High carrying capacity.

(3) Good thermal stability

(4) Strong chemical stability

(5) Radiation resistance

(6) High vacuum resistance

2) Graphite

In the friction state, graphite can slide along the crystal layers and oriented along the friction direction. Graphite has good adhesion to the surface of steel, chromium, and rubber. Therefore, under normal conditions, graphite is an excellent lubricant.

However, when the adsorption film is desorbed, the friction and wear properties of graphite will deteriorate. Therefore, it is generally inclined to use graphite as a lubricant on the surface of oxidized steel or copper.

3) Graphite fluoride

Compared with graphite or molybdenum disulfide, it has better wear resistance, which is due to the stronger binding energy of fluorocarbon bonds. The distance between layers is much larger than graphite, so it is easier to shear between layers.

Due to the introduction of fluorine, its performance under high temperature, high speed, and high load conditions are better than graphite or molybdenum disulfide, which improves the lubricating performance of graphite in the absence of moisture.

4) Boron nitride

Boron nitride is a new type of ceramic material that can be sintered under high temperature and high pressure.

The density of boron nitride is 2.27g/cm3 and the melting point is 3100~3300℃;

The Mohs hardness is 2; the coefficient of friction in air is 0.2, while in a vacuum is 0.3; the thermal stability in the air is 700°C, and in a vacuum is 1587°C.

It is corrosion-resistant, has good electrical insulation, and has a specific resistance greater than 10-6Ω. cm; The compressive strength is 170MPa;

The coefficient of thermal expansion in the c-axis direction is 41×10-6/℃ and in the d-axis direction is -2.3×10-6;

The maximum operating temperature is 900°C in an oxidizing atmosphere, while it can reach 2800°C in an inactive reducing atmosphere.

But the lubrication performance is poor at room temperature, so it is often mixed with fluorinated graphite, graphite, and molybdenum disulfide as a high-temperature lubricant.

Dispersing boron nitride powder in oil or water can be used as a lubricant for drawing or pressing. Used as a lubricant for sliding parts in high-temperature furnaces, boron nitride sintered bodies can be used as materials for bearings and sliding parts with self-lubricating properties.

5) Silicon nitride

Silicon nitride belongs to the hexagonal crystal system and is a ceramic material. It does not have a layered structure like graphite, nor does it have the plastic fluidity like lead oxide. Because of the high particle hardness, it does not have lubricity in the powder state.

However, the surface of the formed body is properly finished, and the number of micro-protrusions in contact with it is reduced, which can exhibit a low friction coefficient. According to the research results, the friction coefficient can reach 0.01 when the surface is finished to 0.05~0.025μm.

The grindability of silicon nitride varies with conditions such as ambient atmosphere, load, speed, and surface roughness. Good abrasion resistance under dry friction conditions.

6) PTFE

Teflon has good chemical stability and thermal stability. It does not react with concentrated acids, concentrated alkalis, and strong oxidants at high temperatures. Even if it is boiled in aqua regia, its weight and performance will not change.

Moreover, it can maintain good chemical stability, thermal stability, and lubricity in a wide temperature range and almost all environmental atmospheres.

Polytetrafluoroethylene has anisotropic properties, and it can also be well oriented under sliding friction conditions.

Its friction coefficient is lower than graphite and MoS2. Generally, the friction coefficient of PTFE to steel is often cited as 0.04. Under high load conditions, the friction coefficient will be reduced to 0.016.

7) Nylon

The friction coefficient of nylon decreases with the increase of load. Under high load conditions, the friction coefficient can be reduced to about 0.1 to 0.15; when there is oil or water on the friction surface, the friction coefficient has a greater downward trend.

The friction coefficient of nylon also decreases with the increase of speed or surface temperature.

Nylon has good abrasion resistance, especially in an environment with a large amount of dust and mud, and its abrasion resistance is unmatched by other plastics.

When there is mud, sand, dust, or other hard materials on the friction surface, the wear resistance of nylon is better than that of bearing steel, cast iron, or even carbon steel with a chrome-plated hardened surface.

When applying nylon materials, special attention should be paid to the selection of materials that oppose each other. When there are hard particles in the friction interface, the wear resistance of nylon is not comparable to that of ordinary steel.

For example, when nylon bushings are used to replace watch copper bushings, the shaft is worn out, and the shaft is not easy to replace parts. It will bring serious consequences if it is worn out.

The disadvantages of nylon are strong moisture absorption, high water absorption, and poor dimensional stability, which is more prominent in cast nylon.

Nylon has a small thermal conductivity coefficient, a large thermal expansion coefficient, and the friction coefficient is not low, so it is best used under the conditions of oil lubrication and special cooling devices.

8) POM

Polyoxymethylene is an opaque milky white crystalline linear polymer. It has a high melting point and high crystallinity thermoplastic engineering plastic with good comprehensiveness and color difference. It is one of the varieties of plastics whose mechanical properties are closer to those of metals.

It has good dimensional stability, water resistance, impact resistance, oil resistance, chemical resistance, and abrasion resistance.

Its coefficient of friction and wear is low, and it is suitable for parts that have been subjected to friction and sliding for a long time, such as machine tool rails. When used in moving parts, no lubricant is required, and it has an excellent self-lubricating effect.

9) Polyimide

The long-term use temperature of phenylene polyimide is 260°C, and it has excellent friction resistance, wear-resistance, and dimensional stability.

It has excellent oil resistance and organic solvent resistance and can withstand general acids, but it will undergo oxidative degradation under the action of strong oxidants such as concentrated sulfuric acid and fuming nitric acid, and still has excellent dielectric properties at high temperatures.

But it is not alkali-resistant and the cost is higher. It has very little wear under high load and high speed in an inert medium.

10) Polyparaben

Polyparaben is a fully aromatic polyester resin. The molecular structure is linear molecules, but the crystallinity is high (greater than 90%), making it difficult to melt and flow, so it has the molding properties of thermosetting resin.

It is similar to metal in performance and has the highest thermal conductivity and thermal stability in the air in plastics. It also presents a non-viscous flow similar to metal at high temperatures.

It is a self-lubricating material with an extremely low friction coefficient, which can reach 0.005, which is even lower than when lubricating oil or grease.

It can be used as a coating material for corrosion-resistant pumps and titanium alloys for supersonic aircraft shells.

However, its thermoforming is more difficult because it requires high-speed high-energy forging, or plasma spraying, and general metal processing methods.

11) Soft metal

Soft metals such as gold, silver, tin, lead, magnesium, and indium can be used as solid lubricants. Soft metals can be used alone or together with other lubricants.

There are two application methods. One is the application in the form of thin films, which uses low-melting soft metals such as lead, zinc, tin, and alloys as dry films. Although copper and bronze are not low-melting, they can sometimes be used in this way.

Another method of use is to add soft metals to alloys or powder alloys as lubricating ingredients to take advantage of their lubricating effects.

For example, general white alloys (bearing alloys), oil film bearing alloys (Kelmet), etc. contain soft metals such as lead, antimony, zinc, tin, and indium, as well as sintered alloy friction materials and brush materials, collecting rings and contacts, etc. Can be used containing soft metals such as silver, gold, and other ingredients.

The coefficient of friction of soft metal is relatively large, but when used with lubricating oil, its friction coefficient and wear can be reduced. The film thickness has a greater impact on the lubrication of soft metal.

If the thickness of the smoke film is less than 0.1m, the lubricating film is easy to break. When it is thicker than 0.01mm, the friction coefficient increases, so it should have an appropriate thickness.

DGMF Mold Clamps Co., Ltd manufactures the mold clamps, supplies the injection mold components, such as Clamps, Toggle Clamps, C Clamps, Pins, Bushings, Positioning Components, Lock Mold Components, Reset Extrusion, Cavity, and Core Components, Coolings, Die Press Components, Punch And Die, Guide Components, Self-lubricating Components, Springs, Machine Tools, gate valves, Machine Mounts, Vises, Fasteners, Lifting, Bolts, Nuts, Washers, etc.

Contact the DGMF Mold Clamps teams for more details about the Self-Lubricating Components such as Self-Lubricating Components specifications, Self-Lubricating Components pricing, Self-Lubricating Components inventory, etc.

Showing all 2 results