Clamps

-

ZHUSHI Mold Clamp

Read more -

U-Type Mold Clamps

Read more -

U Mold Clamps For Injection Molding

Read more -

Threaded Rod Extension Nuts

Read more -

Tapped End U-Clamp

Read more -

T Slot Clamps

Read more -

T Slot Bolts

Read more -

T Bolts For Milling Machine

Read more -

T Bolts And Nuts

Read more -

T Bolt Mould Clamp Set

Read more -

Stepped Strap Clamps

Read more -

Step Block Mold Clamps

Read more -

Stamping Die Clamp

Read more -

Quick-release Toggle Clamps

Read more -

Quick-Change Mold Clamps

Read more -

Quick-change Arching Mold Clamps

Read more -

Push-pull Type Toggle Clamps

Read more -

Pipe Vices

Read more -

Pipe Clamp Bracket

Read more -

Open-Toe Mold Clamps

Read more -

Open Slot Mold Clamp

Read more -

No-Twist Mold Washer

Read more -

Mould Clamps For Injection Moulding

Read more -

Mold Clamps for Injection Molding Machine

Read more -

Mold Clamps For Injection Molding

Read more -

Mold Clamping Stud With Spanner

Read more -

Mold Clamp Washers

Read more -

Mold Clamp M16

Read more -

Mold Clamp Assembly

Read more -

Mold Base Clamp

Read more -

Milling Machine T-Slot Nuts

Read more -

Latch Acting Type Toggle Clamps

Read more -

Injection Moulding Die Clamp

Read more -

Injection Mould Clamp

Read more -

Injection Mold Toe Clamps

Read more -

Injection Mold Clamps

Read more -

Hose Clamps Hose Fittings

Read more -

Horizontal Acting Toggle Clamps

Read more -

Hold Down Clamps

Read more -

High-Quality 58pc T-slot Clamping Kit

Read more -

High-Quality 58pc Deluxe Steel Clamping Kit

Read more -

Heavy-duty Mold Clamp

Read more -

Heavy Hex Nuts

Read more -

Hand Tool Toggle Clamp Handle Clamp

Read more -

Gooseneck Mold Clamp

Read more -

G Clamp

Read more -

Forged U-clamp For Injection Molding

Read more -

Forged U Clamps

Read more -

Forged T Slot Clamps

Read more -

Forged Mould Clamps

Read more -

Forged Mold Clamp For Injection Molding

Read more -

Forged Gooseneck Clamp

Read more -

Forged Goose Neck Mold Clamps

Read more -

Forged Flange Nuts

Read more -

Forged and Hardened Mold Clamping Stud

Read more -

Forged and Hardened Mold Clamp Bolts

Read more -

Extra Long Coupling Nuts

Read more -

Easy Clamps

Read more -

Dongbo High-Quality 58pcs Clamping Sets

Read more -

DIN 508 T Nuts For Milling Machine

Read more -

CNC Wire Stainless Steel EDM Clamps

Read more -

Closed-Toe Mold Clamps

Read more -

Closed End Mold Clamps

Read more -

Clamps for Fixing Mold

Read more -

Clamping Stud Mould Clamp Set

Read more -

C-Clamp

Read more -

C Type Mould Clamp For Injection Moulding

Read more -

Arching Mold Clamps

Read more -

Arching C Type Mold Clamps

Read more -

Adjustable Clamp Universal Mold Clamp

Read more -

58 pcs Steel Clamping Kit

Read more -

12.9 Grade Square Head T Bolt

Read more

Clamps Supplier Mould Clamps Manufacturer

DGMF Mold Clamps Co., Ltd is the clamps supplier and mould clamps manufacturer in China.

What is a clamp?

Clamp refers to a device used to fix the processed object in the process of mechanical manufacturing so that it can occupy the correct position for accepting construction or inspection.

It is also called the clamping element.

Broadly speaking, in any process in process, a device used to quickly, conveniently, and safely install a workpiece can be called a fixture.

The clamp usually consists of a positioning element (to determine the correct position of the workpiece in the clamp), a clamping device, a tool setting guide element (to determine the relative position of the tool and the workpiece or to guide the direction of the tool), an indexing device (to make the workpiece in a single installation to complete the processing of several workstations, it consists of two types of rotary indexing device and linear moving indexing device), connecting elements and clamp body (clamp base).

Clamp Introduction

For example, welding fixtures, inspection fixtures, assembly clamps, machine tool clamps, etc., of which machine tool clamps are the most common, often referred to as fixtures for short.

When processing a workpiece on a machine tool, in order to make the surface of the workpiece meet the technical requirements of the size, geometry, and mutual position accuracy with other surfaces specified in the drawing, the workpiece must be installed (positioned) and clamped (fixtured) before processing.

Clamp Classifications

The types of fixtures can be divided into:

①Universal clamp

Such as machine vise, chuck, suction cup, indexing head, and rotary table, etc., have great versatility, can better adapt to the transformation of processing procedures and processing objects, its structure has been finalized, size and specifications have been series Most of them have become a standard accessory of machine tools.

②Special clamp

It is specially designed and manufactured for the clamping needs of a certain product part in a certain process. The service object is specific and highly pertinent. It is generally designed by the product manufacturer.

Commonly used are lathe clamps, milling machine clamps, drilling dies (machine tool clamps used to guide the tool to drill or ream holes on the workpiece), boring molds (machine tool clamps for guiding the boring bar to bore holes on the workpiece), and accompanying fixtures (use Mobile fixture on the automatic line of modular machine tools).

③Adjustable clamp

A special fixture that can replace or adjust components.

④Combined fixture

Jigs composed of standardized components of different shapes, specifications, and uses are suitable for single-piece, small-batch production, and temporary tasks where new products are trial-produced and products are frequently replaced.

In addition to vices, chucks, indexing heads, and rotary tables, there is also a more common tool holder. Generally speaking, when the term tool holder appears at the same time, most of this holder refers to a tool holder.

Lathe clamp

The clamps used to process the inner and outer rotating surfaces and end faces of the workpiece on the lathe are called the lathe clamp. Most of the lathe clamps are installed on the spindle, and a few are installed on the saddle or bed.

Milling machine clamp

They are all installed on the milling machine table, and the machine table is used for feed motion. It is mainly composed of a positioning device, clamping device, clamp body, connecting element, and tool setting element.

During milling, the cutting force is relatively large, and the cutting is interrupted, and the vibration is relatively large. Therefore, the clamping force of the milling machine clamp is relatively large, and the rigidity and strength of the clamp are relatively high.

Bearing seat clamp

In order to ensure the production quality of the bearing seat and improve the production quality of the bearing seat, in addition to the use of machine tools and other mechanical equipment, a large number of process equipment will be used, including bearing seat clamps, molds, cutting tools and related auxiliary tools.

Bearing seat clamp is a production tool specially used to ensure the quality of bearing seat products, which can make the production process of bearing seats more convenient.

Different bearing seat clamps are different according to their different structures and forms, working conditions, and design principles.

Therefore, there are many types and styles of bearing seat clamps, which occupy a large proportion in both quantity and style.

This kind of bearing holder clamp can be used to accurately determine the relative position of the processed workpiece and the props, that is, the workpiece to be processed can be tightened, so that the movement that needs to be performed during the processing of the workpiece can be completed.

Since the bearing seat clamp plays a very important role in the production process of the bearing seat, the drawing of the bearing seat clamp design drawing is also very important.

Three coordinate clamp

Used on the measuring machine, using its modular support and reference device to complete the flexible fixation of the measured workpiece.

The device can be automatically programmed to support the workpiece and establish unlimited reference points for workpiece configuration.

The advanced special software can directly pass the geometric data of the workpiece and generate the clamping program of the workpiece in a few seconds.

Industrial robot clamp

All are installed on industrial robots and used in industrial automation equipment. It is one of the new advanced technologies of modern industrial automation equipment. The main form of cooperation with robots appears in modern industrial production. The common usage is in automatic unmanned factories such as machine tool loading and unloading, workpiece destacking, welding, and grinding.

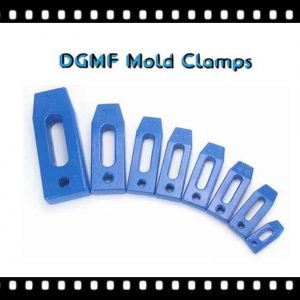

Mold clamps

There are two processing standards for mold clamps. National Standard Machinery Standard: GB∕T 699-1988. The second type of machinery department standard JB∕T 8044-1999.

Die pressing includes a U-shaped mold clamp, universal mold clamp, forged mold clamp, easy clamp, open-end mold clamp, closed-end mold clamp, machined mold clamp, injection mold clamp, stamping mold clamp, etc.

A mold clamp is a kind of auxiliary fixture often used in injection molding processing. Its main function is to make the workpiece not vibrate or shift during processing. To ensure the accuracy of the molded workpiece and a good finish.

Therefore, the quality of the mold pressing plate directly affects the product quality of the mold. Therefore, the mold platen plays a vital role in the mold manufacturing process. The die plate has high strength, is small in size, is flexible, and has a simple operation.

Toggle clamp

A toggle clamp is a mechanical device that is operated manually to locate equipment and objects. Sometimes called a quick clamp, you can understand that it is a clamping part, the clamping force is as small as tens of N, as large as several thousand N, choose the appropriate clamp according to your needs.

It can be used for all workpiece stations that require positioning and clamping for mass production. It is usually used in welding, inspection tools, molds, etc.

The basic divisions are as follows. Horizontal toggle clamps, vertical toggle clamps, push-pull toggle clamps, linear motion toggle clamps, precision toggle clamps, heavy-duty self-locking toggle clamps, extrusion toggle clamps.

DGMF Mold Clamps Co., Ltd manufactures the mold clamps, supplies the injection mold components, such as Clamps, Toggle Clamps, C Clamps, Pins, Bushings, Positioning Components, Lock Mold Components, Reset Extrusion, Cavity, and Core Components, Coolings, Die Press Components, Punch And Die, Guide Components, Self-lubricating Components, Springs, Machine Tools, gate valves, Machine Mounts, Vises, Fasteners, Lifting, Bolts, Nuts, Washers, etc.

Contact the DGMF Mold Clamps teams for more details about the clamp such as clamp specifications, clamp pricing, clamp inventory, etc.